Digital master control system of mine hoist

A master control and hoist technology, which is applied in the direction of elevators, transportation and packaging, etc., can solve the problems of signal error, analog signal instability, increase the workload and labor intensity of hoist operators, and achieve the improvement of electrical science. Technical content, improve anti-jamming performance, and protect the user's interests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

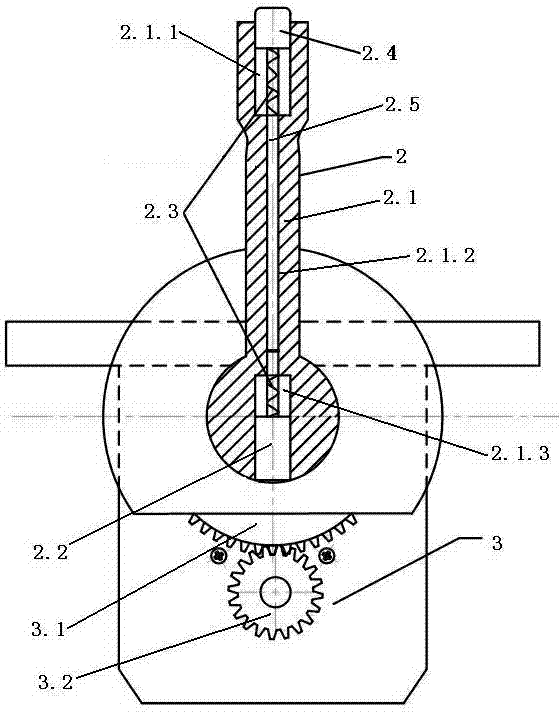

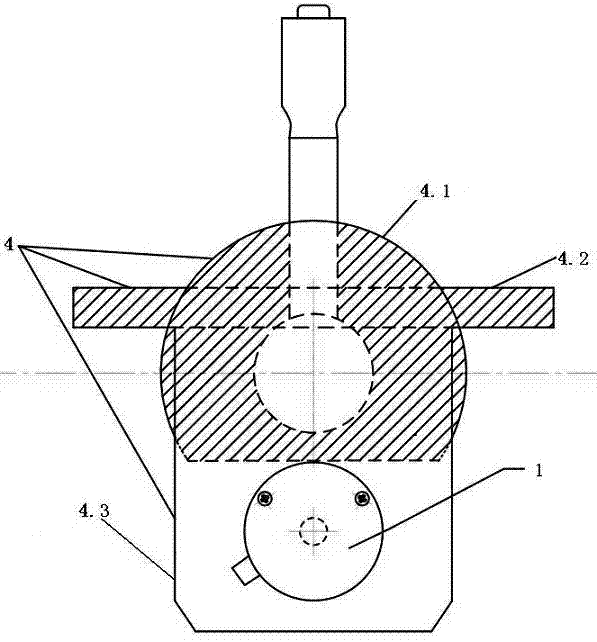

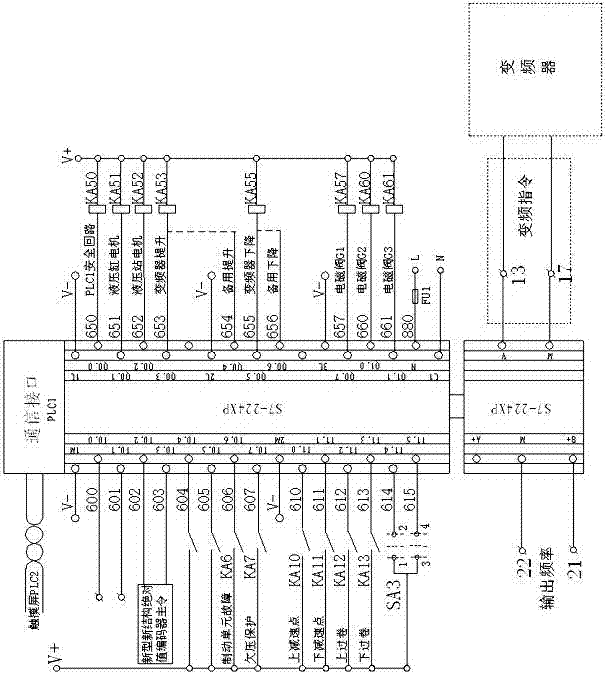

[0020] like figure 1 , 2 As shown, a digital mine hoist master control system includes an absolute value encoder 1, a zero self-locking handle mechanism 2, a transmission gear 3, and an encoder fixing device 4. The encoder fixing device 4 includes a rotary The circular body 4.1, the fixed panel 4.2, and the encoder fixed plate 4.3, the fixed panel 4.2 is fixed vertically on one side of the rotating circular body 4.1, the encoder fixed plate 4.3 is fixed on the lower bottom surface of the fixed panel 4.2, the The transmission gear 3 described above is composed of a gear one 3.1 and a gear two 3.2. The gear one and the zero position self-locking handle mechanism 2 are coaxially rotated and installed at the center of the rotating circle 4.1, and the gear two 3.2 is rotated and installed on the On the side of the encoder fixing plate 4.3 below the gear one 3.1, the gear one 3.1 and the gear two 3.2 mesh with each other, and the absolute encoder 1 is rotatably installed on the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com