a shaft sleeve

A technology of shaft sleeves and cylinders, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of inconvenient fastening installation, increase of installation size and weight, poor coaxiality, etc., to increase feedback function, overcome Effect of adding weight and reducing product weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better illustrate the present invention, it will be described in detail below in conjunction with the accompanying drawings.

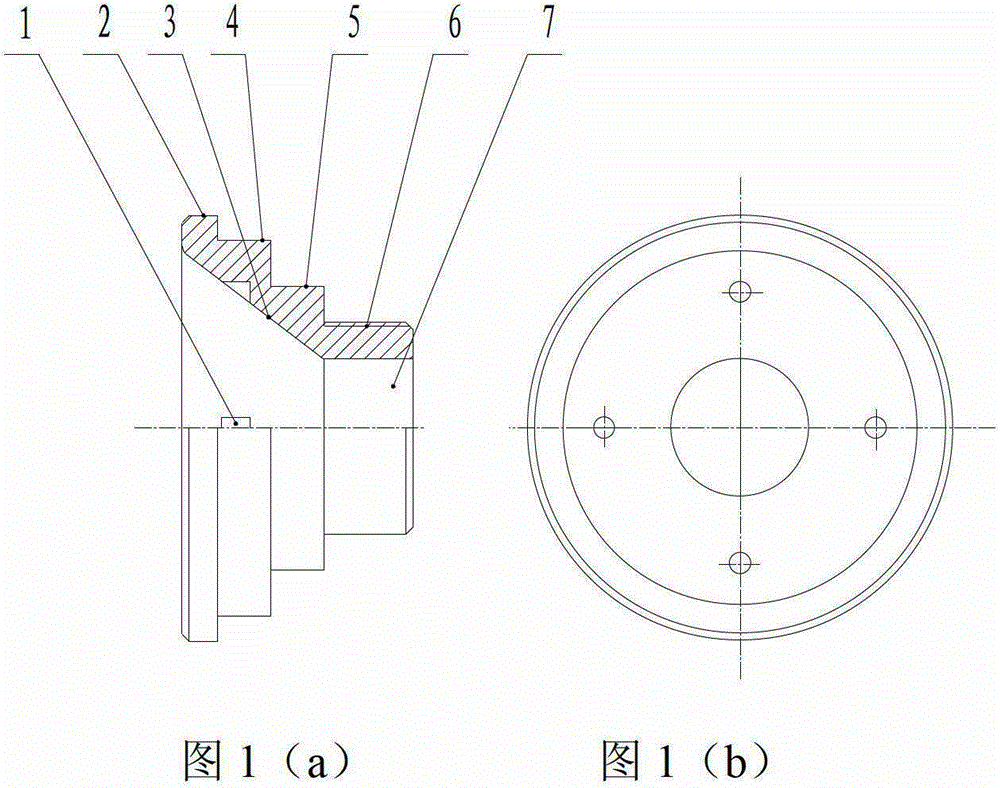

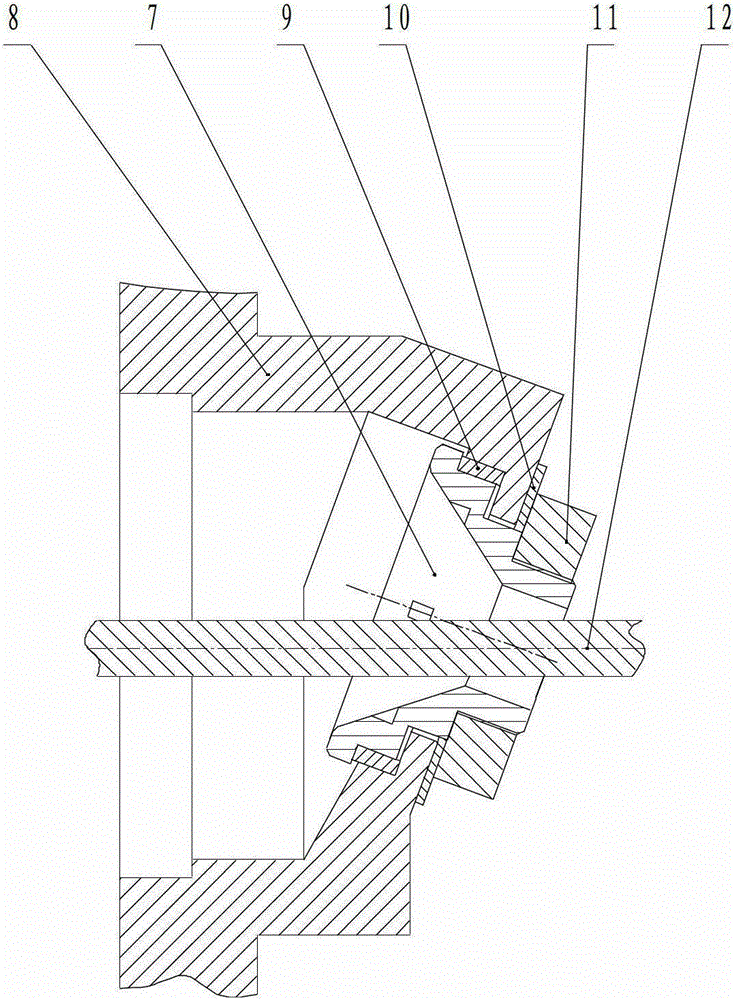

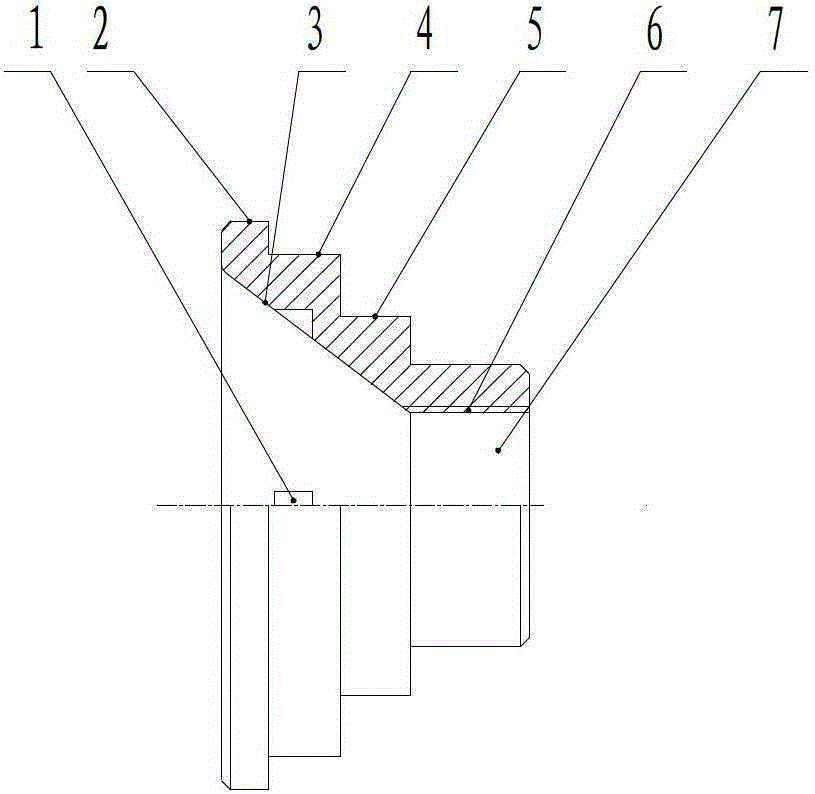

[0015] Please refer to Figure 1~ figure 2 , which is the first structural diagram and structural implementation of the bushing of the present invention.

[0016] A shaft sleeve includes a cone part and a cylinder part. The hollow cone part is provided with a flange surface 2, a positioning shoulder 4 and a matching shoulder 5. The inner surface of the hollow cone is a cone surface, and the inner surface is provided with a tightening The direction of the pin hole 1 and the fixing pin hole 1 are parallel to the axis of the cone, and the cylindrical part cooperates with the housing 8. In this embodiment, the thread 6 is located on the outer surface of the cylindrical part. The shaft sleeve 7 is installed in an inclined plane housing 8, and is positioned by the flange surface 2 and the positioning sleeve 9. When installing, insert the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com