Heat dissipation method and structure of an array LED light source panel

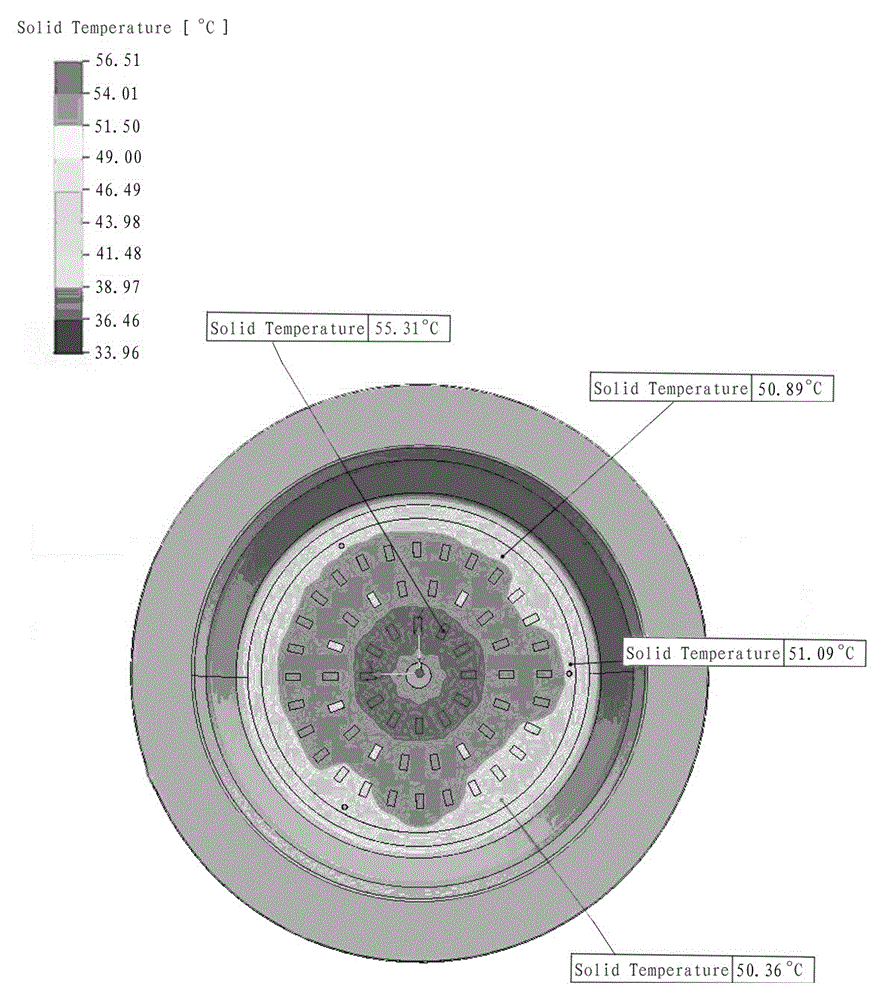

A technology of LED light source and heat dissipation method, which is applied in the direction of light source, plane light source, point light source, etc., can solve the problems of increasing panel production cost and complicated process, and achieve uneven heat distribution, prolong service life, and reduce temperature rise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

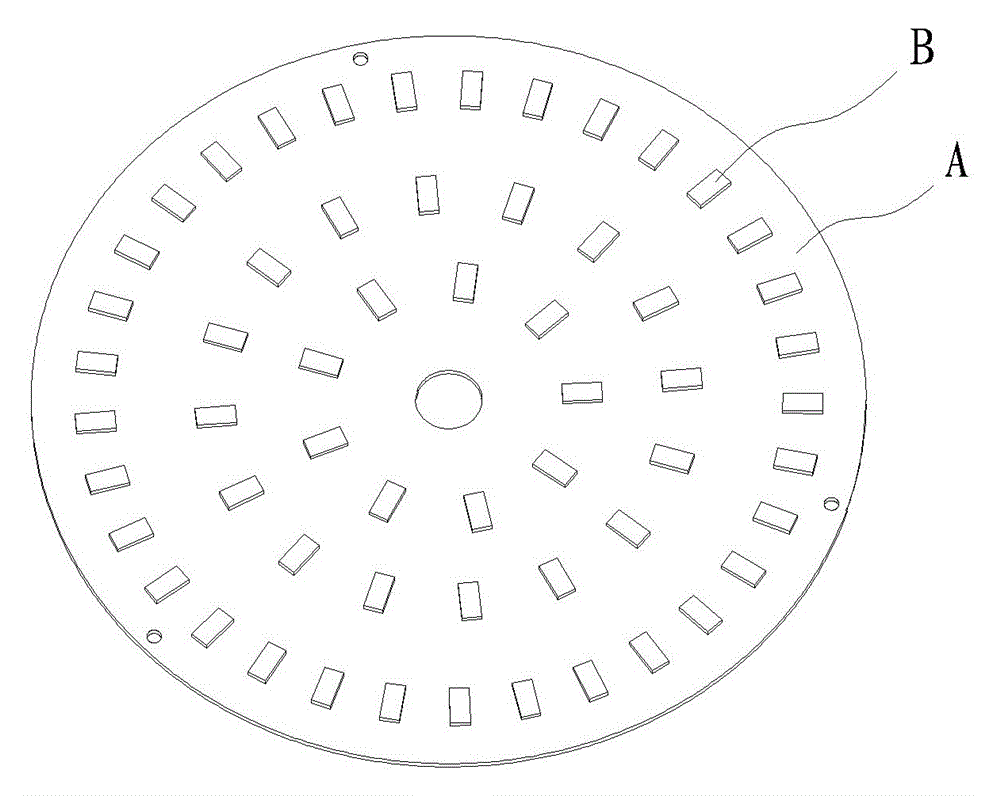

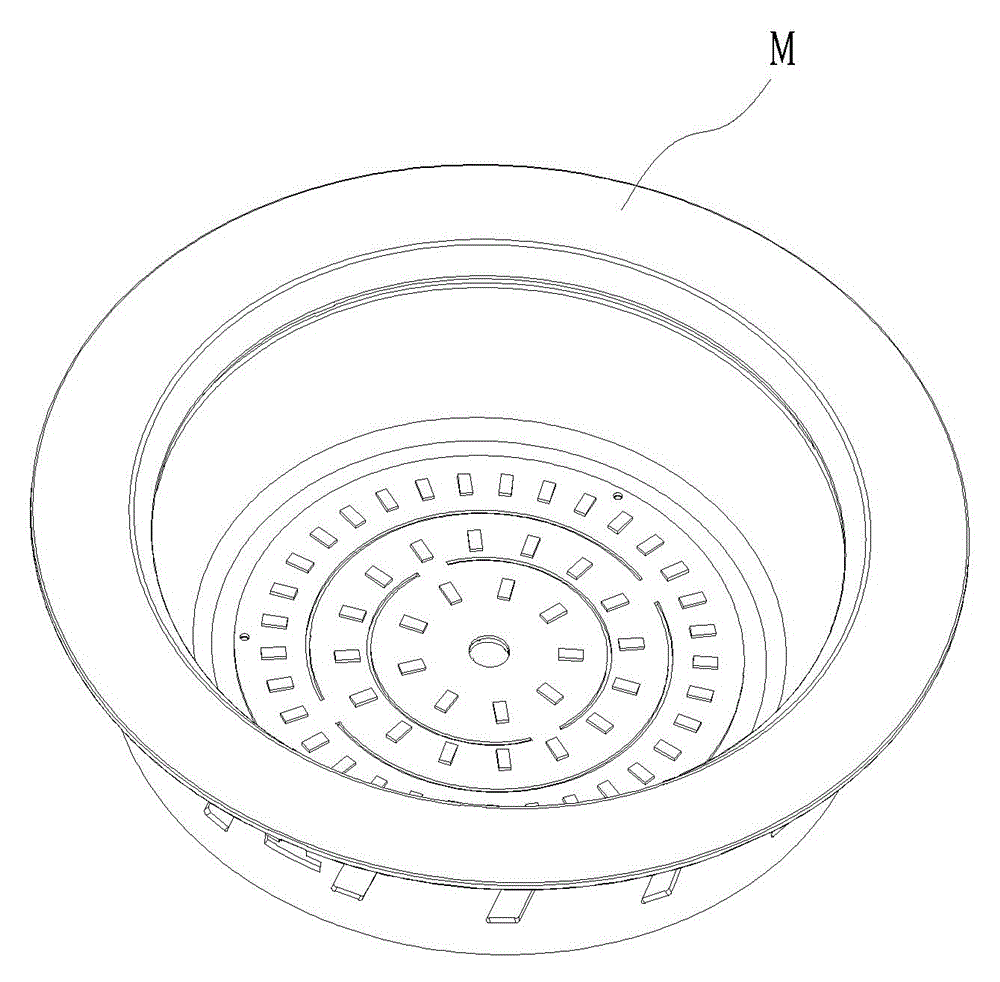

[0022] Example: see image 3 , Figure 4 or Figure 5 , A heat dissipation method for an array LED light source panel. A number of LEDs are provided on the light source panel 1 to form an LED ring with two or more arrays along the center and outwards. The heat dissipation panel 1 is provided between the adjacent inner and outer LED rings. In the matched heat insulation groove 3, each LED and the corresponding heat insulation groove form a heat dissipation channel so that heat can be quickly transferred to the back of the panel. The light source panel 1 is a printed board such as an aluminum substrate with a circular shape as a whole. image 3 , The LEDs on it are distributed in a circular array with the center of the substrate mounting hole as the center, the heat insulation grooves between adjacent LED rings are arranged at the above center, and the corresponding heat dissipation area of each LED is the same. The light source panel 1 may also be a printed board such as an alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com