Bunching type horizontal loading follow-up weight deducting device

A horizontal loading and tare technology, applied in the testing of measuring devices, instruments, mechanical parts, etc., can solve problems such as the inability to guarantee the correct weight deduction, the inability to meet the requirements of the follow-up tare, and the difficulty in setting the key points of the fixed buckle. The effect of strong performance, low cost and simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

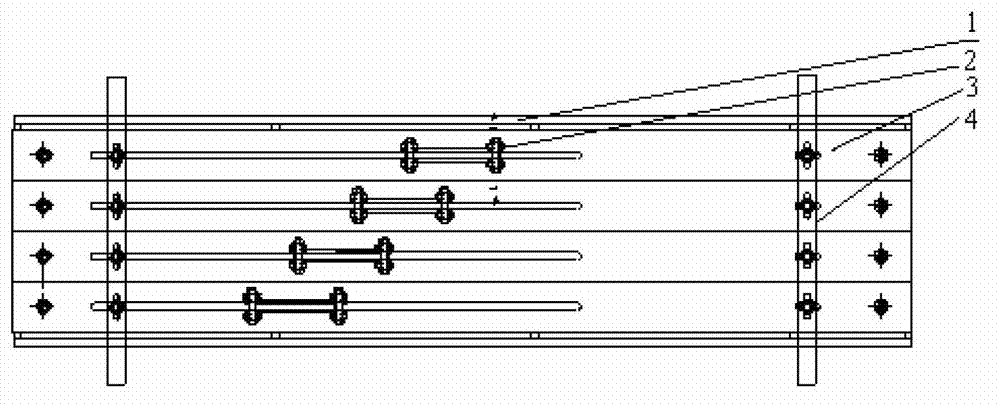

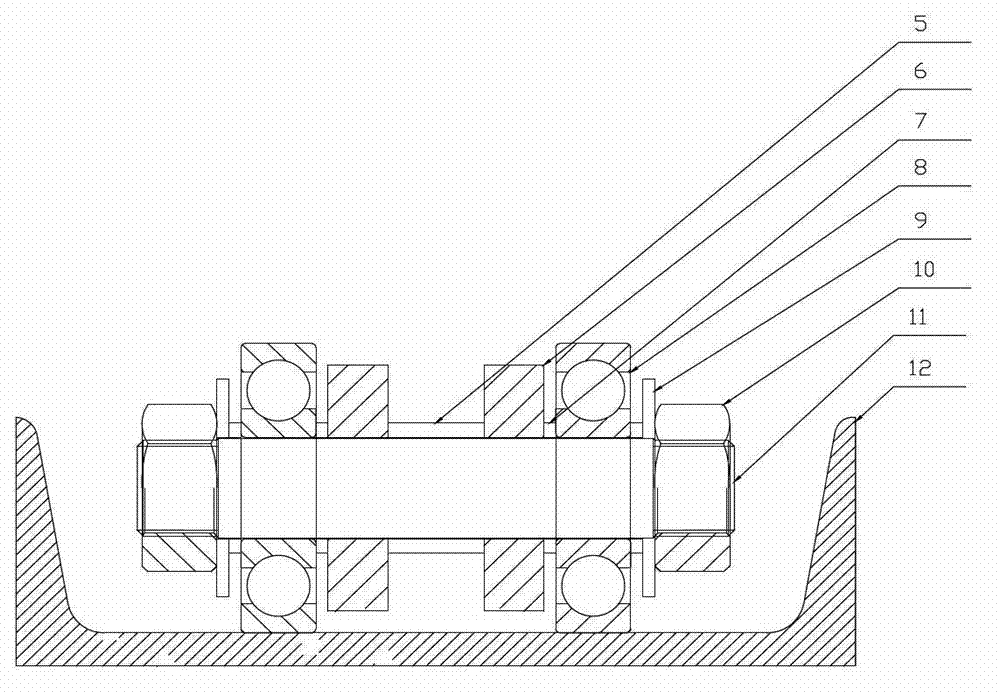

[0024] Please also see figure 1 and figure 2 , the present invention's grouped horizontal loading follow-up tare device comprises a sliding trolley 1, a trolley track 3 and a buckle connector (the connector generally adopts a steel cable); , bushings 7 and 9, and rolling bearings 7 arranged at both ends of the pull plate; the trolley track 3 is spliced by a number of sub-tracks 12, and each sub-track is preset with the follow-up deformation and motion track of the sliding trolley, and is composed of The fixed plate 4 is connected and can be assembled or disassembled according to the usage conditions.

[0025] In this embodiment, the grouped horizontal loading follow-up buckle device of the present invention is mainly realized through the following technical solutions:

[0026] a) The sliding trolley composed of rolling bearings and the trolley track composed of channe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap