Method for producing a control element for an air-diffuser, control element for an air-diffuser, and air-diffuser

一种排风装置、操作元件的技术,应用在气流控制元件、应用、加热方式等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following description of the preferred embodiment of the invention, the descriptions of "front", "rear", "horizontal", "vertical", etc. refer to the installation situation of the air exhaust device which is common in automobiles and known to the person skilled in the art , where for example the term "front side" denotes the side facing the interior to be ventilated.

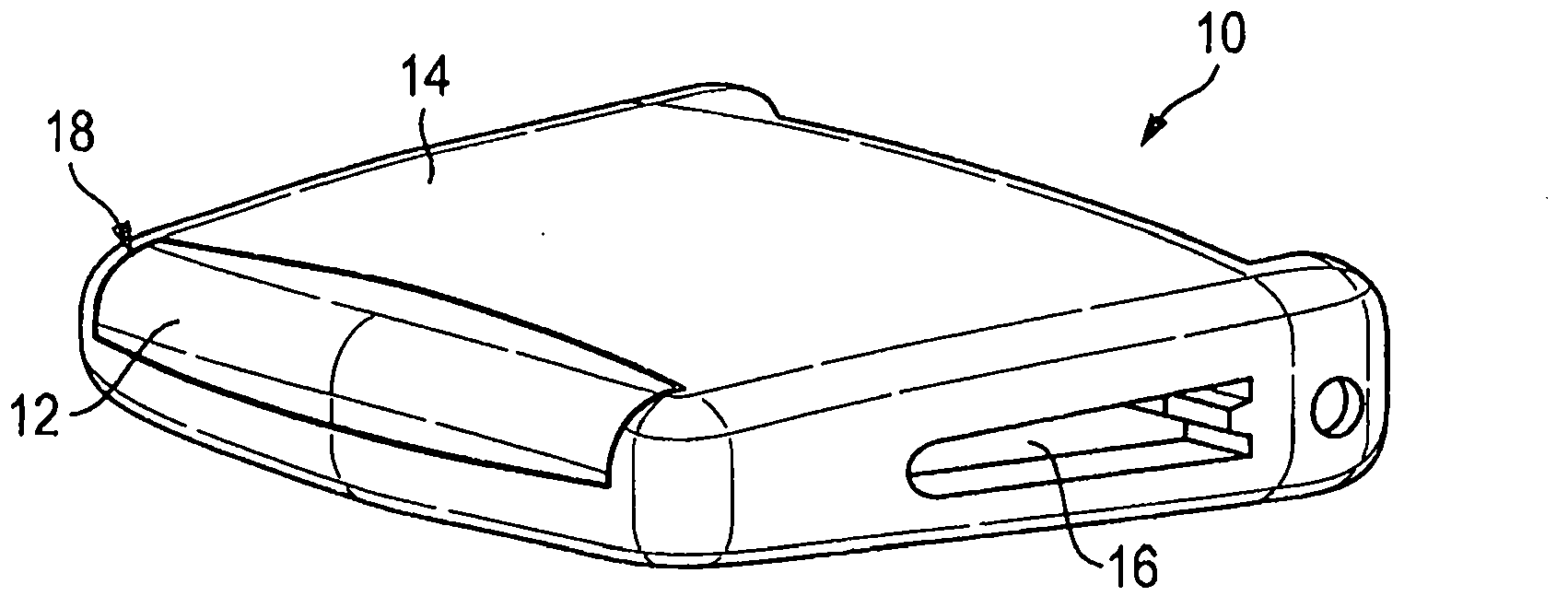

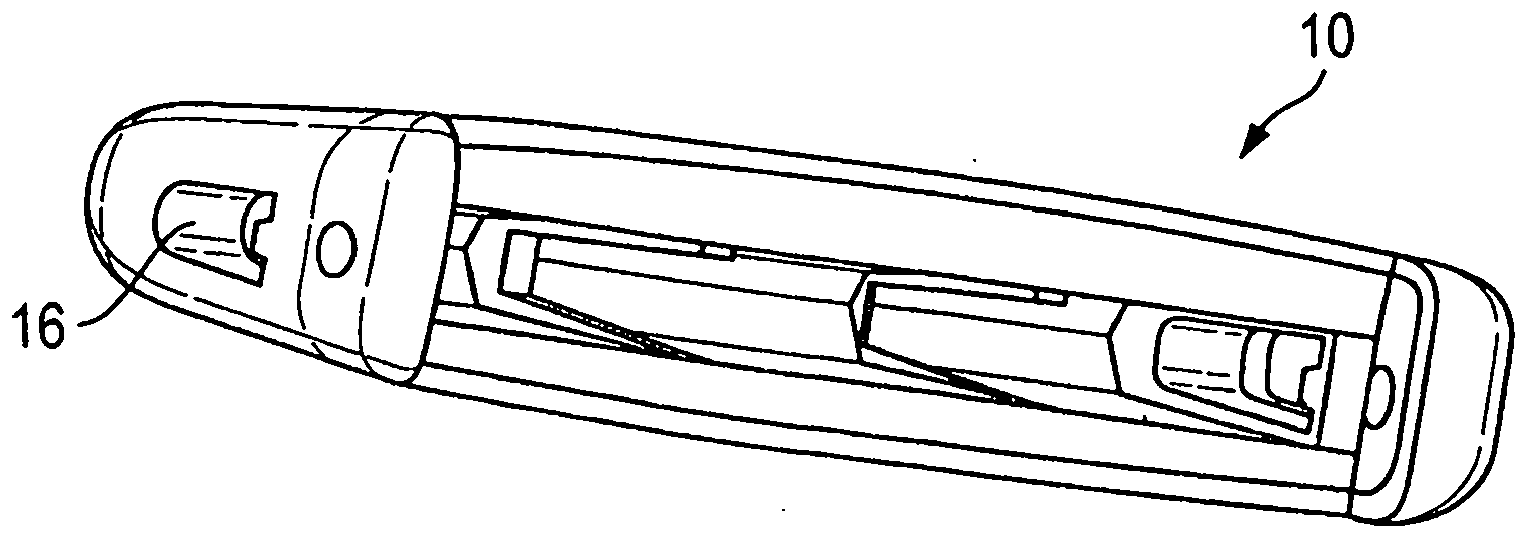

[0040] exist figure 1 and 2 A first embodiment of an operating element 10 for a fan is shown in . The operating element 10 is essentially formed from two interconnected subelements 12 , 14 . A flat channel 16 extends transversely through the entire operating element 10 from one side to the opposite side.

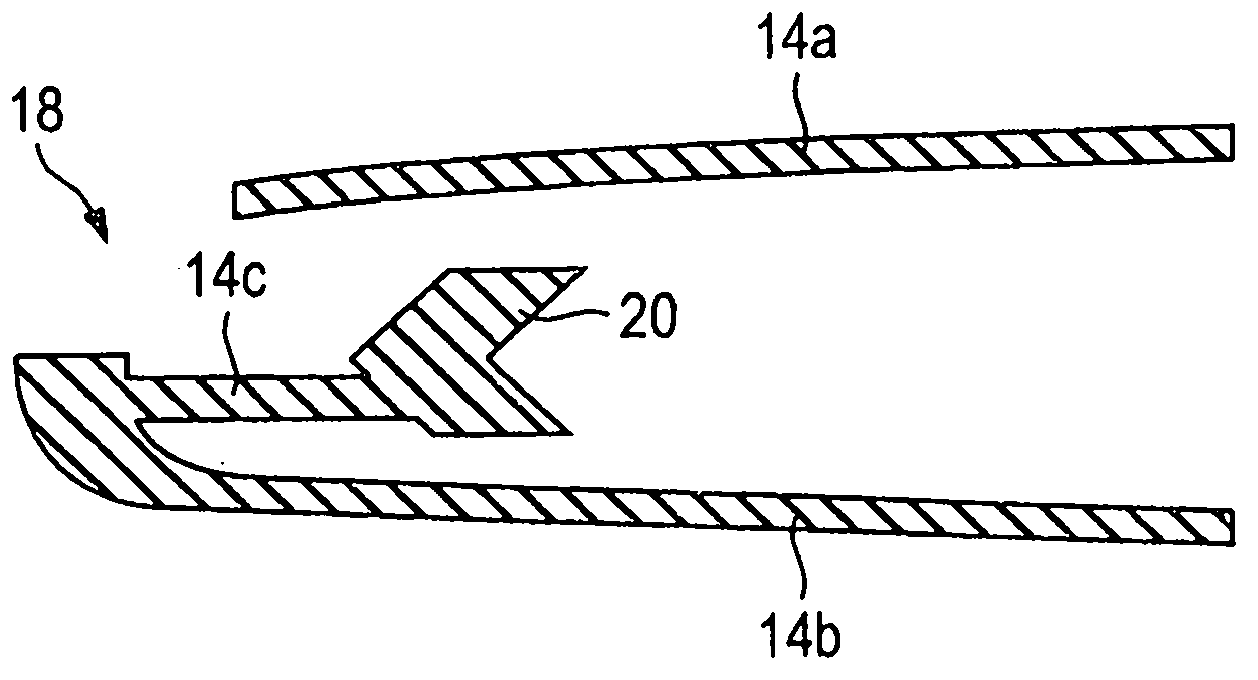

[0041] The first sub-element 12 is almost completely surrounded by the second sub-element 14 , in particular in the region where the user grips during handling. However, the front end of the first partial element 12 is visible through the recess 18 of the second partial element 14 on the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com