Mounting structure of machine tool centre and centre shaft

An installation structure and tip shaft technology, which is applied in the direction of tailstock/tip, toolholder accessories, turning equipment, etc., can solve the problem of difficulty in ensuring the matching accuracy of tip 1 and tip shaft 2, easy relative displacement, troublesome adjustment of tip 1, etc. Problems, achieve the effect of overcoming the defects of the installation structure, convenient correction, and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

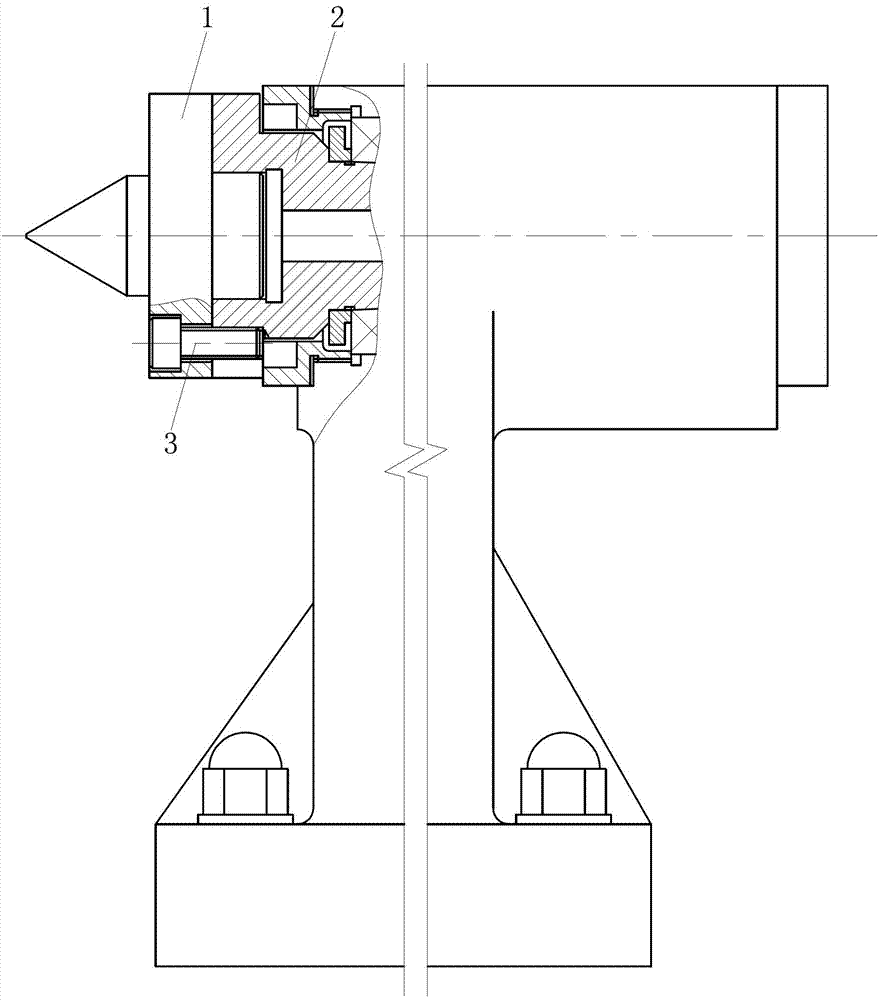

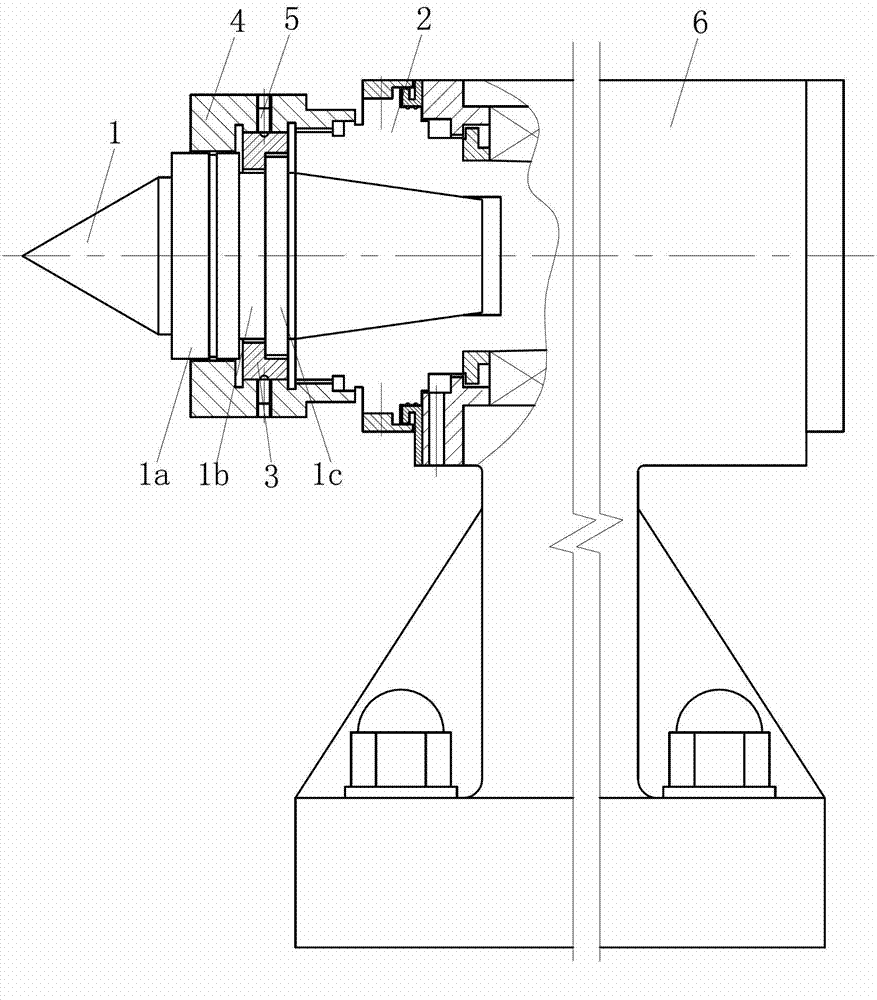

[0019] Such as Figures 2 to 6 As shown, the installation structure is composed of the top 1, the top shaft 2, the retaining ring 3, the nut sleeve 4, the locking screw 5 and the top seat 6. Wherein, the tip shaft 2 is installed in the installation hole of the tip seat 6, and its installation structure adopts the existing structure, which will not be repeated here.

[0020] The right part of the tip 1 is inserted into the mounting hole on the left part of the tip shaft 2 . As one of the improvements of the present invention, the right part of the tip 1 is a Morse taper section, and the installation hole on the left part of the tip shaft 2 is a corresponding Morse taper hole.

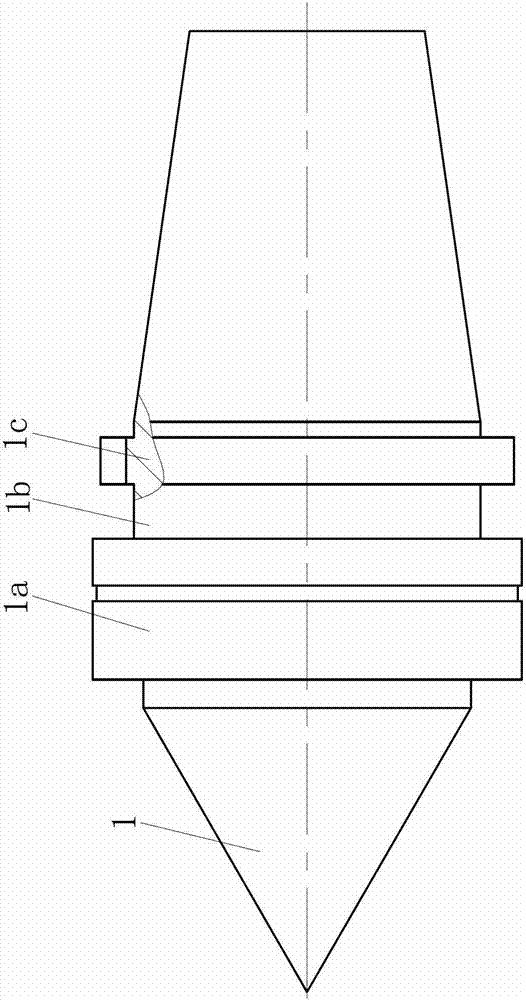

[0021] As the second improvement point of the present invention, the middle part of the shaft body of the tip 1 is sequentially composed of a large diameter section 1a, a small diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com