Handmade soap composition, handmade soap and preparation method thereof

A technology of handmade soap and composition, which is applied in the manufacture of soap detergent composition, detergent composition, soap solution, etc., which can solve the problems of nutrient loss, product pollution, low utilization rate, etc., and achieve dry and moisturizing effect Good effect and long shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

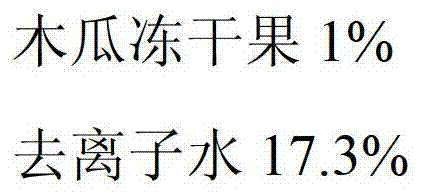

Embodiment 1

[0023] A kind of handmade soap composition, it is made up of the component of following percentage by weight:

[0024]

[0025]

[0026] Put the above-mentioned coconut oil, palm oil, olive oil, sweet almond oil, and shea butter into the reactor in sequence, turn on the agitator (10rpm) and stir evenly, raise the temperature to 31°C, and keep warm for later use;

[0027] Under rapid stirring (30rpm), dissolve sodium hydroxide in an appropriate amount of water, and cool to 31°C after completely dissolving;

[0028] Slowly add the above sodium hydroxide solution into the reactor and stir rapidly (30rpm) until the soap becomes thick (viscosity 6000mPa.s~8000mPa.s);

[0029] After dispersing the freeze-dried fruit of papaya with the remaining deionized water, add it into the reactor and stir evenly;

[0030] Pour the soap solution into the pre-prepared mold, cover the mold with a plastic film, and put it in a 31°C incubator to stand;

[0031] After 48 hours, demoulding is ...

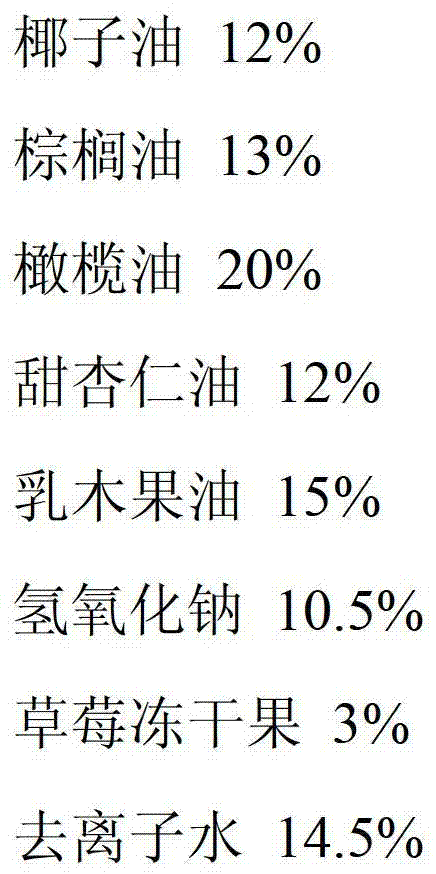

Embodiment 2

[0033] A kind of handmade soap composition, it is made up of the component of following percentage by weight:

[0034]

[0035] Put the above-mentioned coconut oil, palm oil, olive oil, sweet almond oil, and shea butter into the reactor in sequence, turn on the agitator (10rpm) and stir evenly, heat up to 33°C, and keep warm for later use;

[0036] Under rapid stirring (30rpm), dissolve sodium hydroxide in an appropriate amount of water, and cool to 33°C after completely dissolving;

[0037] Slowly add the above sodium hydroxide solution into the reactor and stir rapidly (30rpm) until the soap becomes thick (viscosity 6000mPa.s~8000mPa.s);

[0038] After the strawberry freeze-dried fruit is dispersed with the remaining deionized water, it is added to the reactor and stirred evenly;

[0039] Pour the soap liquid into the pre-prepared mold, cover the mold with a plastic film, and put it in a 33°C incubator to stand;

[0040] After 48 hours, demoulding is carried out, and th...

Embodiment 3

[0042] A kind of handmade soap composition, it is made up of the component of following percentage by weight:

[0043]

[0044] Put the above-mentioned coconut oil, palm oil, olive oil, sweet almond oil, and shea butter into the reactor in sequence, turn on the agitator (10rpm) and stir evenly, raise the temperature to 34°C, and keep warm for later use;

[0045] Under rapid stirring (30rpm), dissolve sodium hydroxide in an appropriate amount of water, and cool to 34°C after completely dissolving;

[0046] Slowly add the above sodium hydroxide solution into the reactor and stir rapidly (30rpm) until the soap becomes thick (viscosity 6000mPa.s~8000mPa.s);

[0047] After dispersing the freeze-dried pumpkin fruit with the remaining deionized water, add it to the reactor and stir evenly;

[0048] Pour the soap solution into the pre-prepared mold, cover the mold with a plastic film, and put it in a 34°C incubator to stand;

[0049] After 48 hours, demoulding is carried out, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com