Method, system and engineering machinery for synchronously controlling multiple oil cylinders

A synchronous control, engineering machinery technology, applied in mechanical equipment, servo motors, servo motor components, etc., can solve the problem of insufficient synchronization of multiple oil cylinders, and achieve the effects of easy adjustment, simple and convenient maintenance, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

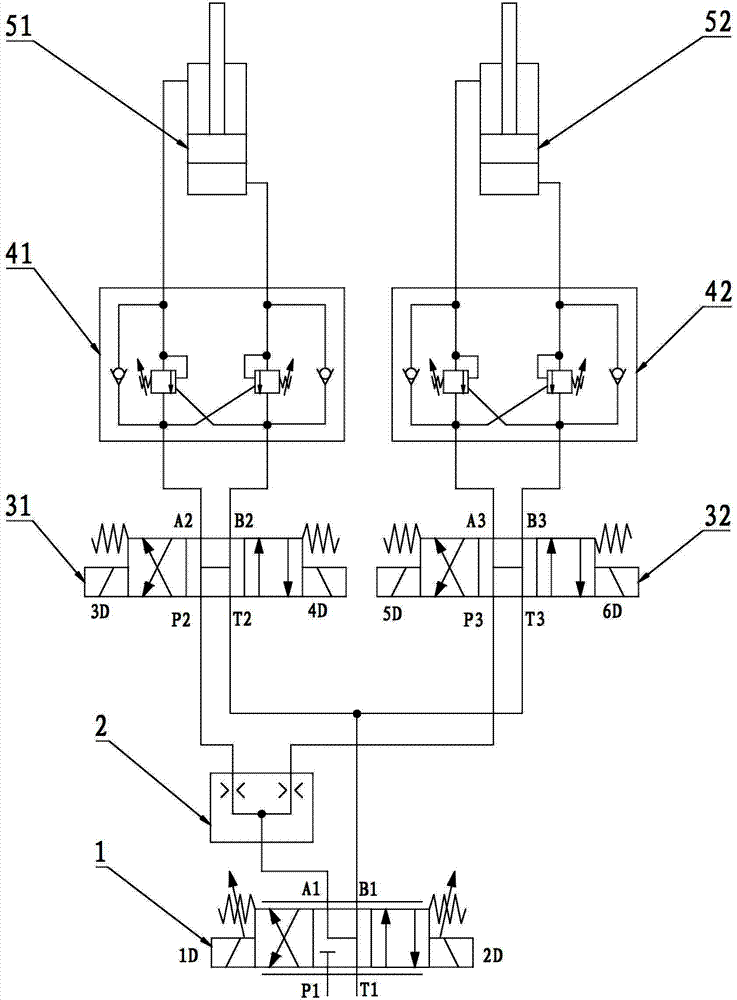

[0023] The multi-oil cylinder synchronous control method described in the embodiment of the present invention is to connect the parallel oil cylinders in series with the balance valve and the reversing valve respectively, and then connect them in series with a diverter valve 2 and a load-sensing valve 1, and the diverter valve 2 The oil inlet is communicated with one working oil port of the load sensing valve 1, the oil outlet of the diverter valve 2 is respectively communicated with the oil inlet of the reversing valve of each oil cylinder, and the other working port of the load sensing valve 1 is The oil port is connected with the oil return port of the reversing valve of each oil cylinder at t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap