Elastic connecting device

An elastic connection and elasticity technology, applied in the direction of elastic coupling, supporting machine, mechanical equipment, etc., can solve the problem of difficult dismantling, inability to solve the problems of eccentricity between shafts, eccentric axial deviation, affecting the six-axis adjustment frame, etc. Easy to dismantle, multi-axis docking is simple and convenient, and the effect of low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Such as Figure 4 As shown in -5, it includes a motor device 3 and an elastic coupling 1. The elastic coupling 1 is connected to the motor output shaft of the motor device 3, and the motor output shaft drives the elastic coupling 1 to rotate.

[0020] Such as Figure 9 , 10 As shown, the elastic coupling 1 includes a connecting piece 11, an elastic structure 12 arranged in the connecting piece 11, an elastic shaft 13, and a limiting plate 14, the limiting plate 14 is fixed on the connecting piece 11, and one end of the elastic shaft 13 is arranged on In the connecting piece 11 , the other end passes through the limiting plate 14 . The limit shaft sleeve 2 is provided with a clamping structure 21, which can clamp the elastic coupling 1, the elastic shaft 13 is clamped into the clamping structure 21, the elastic coupling 1 is connected with the adjustment shaft 7, and the motor The output shaft drives the adjustment shaft 7 to rotate.

[0021] Such as Image 6 As sho...

Embodiment 2

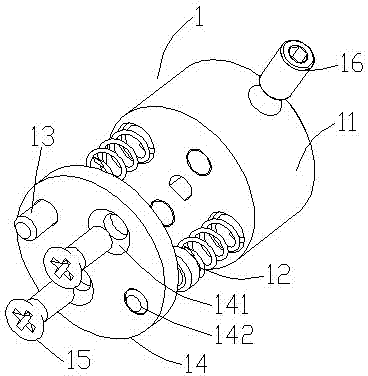

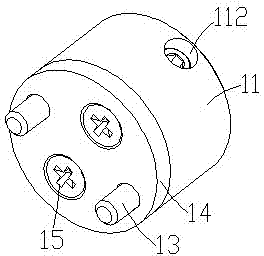

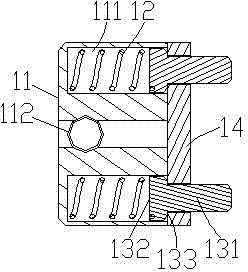

[0023] Such as figure 1 -3, on the basis of Embodiment 1, the specific elastic coupling 1 includes a connecting piece 11, an elastic structure 12 arranged in the connecting piece 11, an elastic shaft 13, a limit plate 14, and the limit plate 14 is fixed on On the connecting piece 11 , one end of the elastic shaft 13 is disposed in the connecting piece 11 , and the other end passes through the limiting plate 14 . The connecting piece 11 includes a blind hole 111 and a circumferential threaded hole 112. The elastic structure 12 is arranged in the blind hole 111. The elastic coupling 1 also includes a fixing piece 16. The fixing piece 16 connects the connecting piece 11 and the motor through the circumferential threaded hole 112. output shaft connection. The elastic coupling 1 also includes a limiting plate fixing member 15, the limiting plate 14 includes a fixing member through hole 141 and an elastic shaft through hole 142, and the limiting plate fixing member 15 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com