Continuous mill inlet threading auxiliary device

An auxiliary device and continuous rolling mill technology, applied in the field of steel rolling, can solve the problems of low efficiency, reduce the degree of automation of the unit, increase the production cost of production enterprises, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

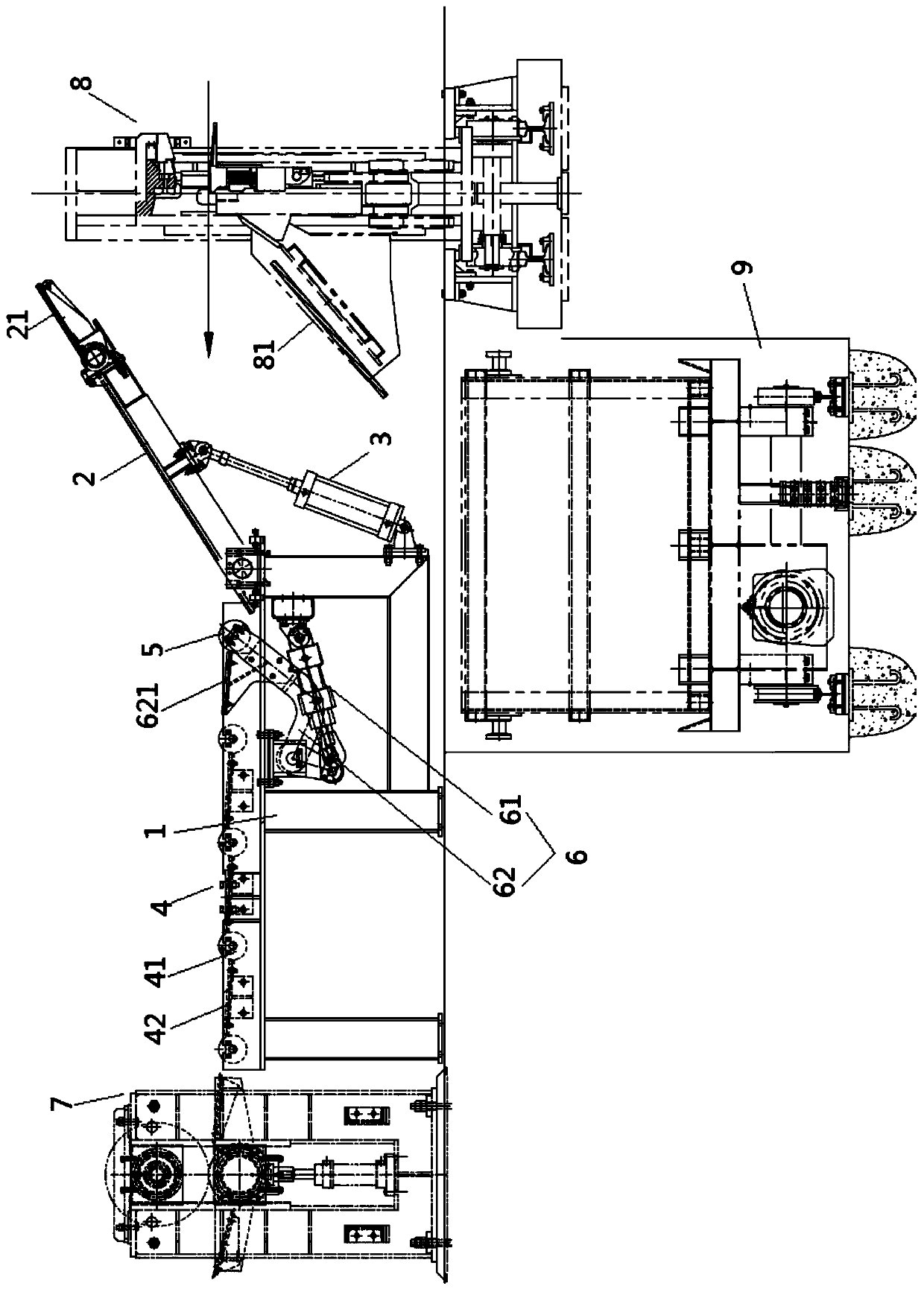

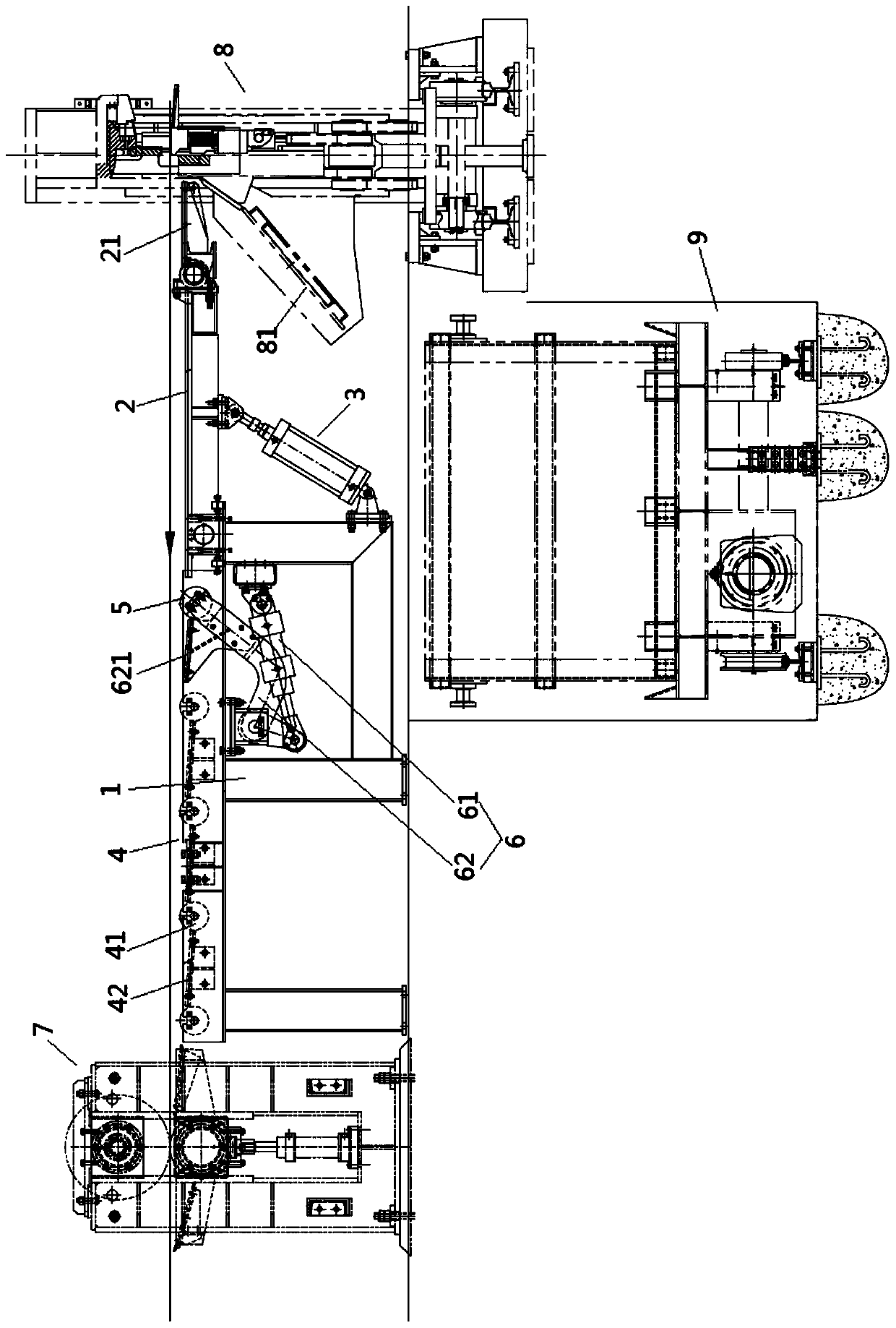

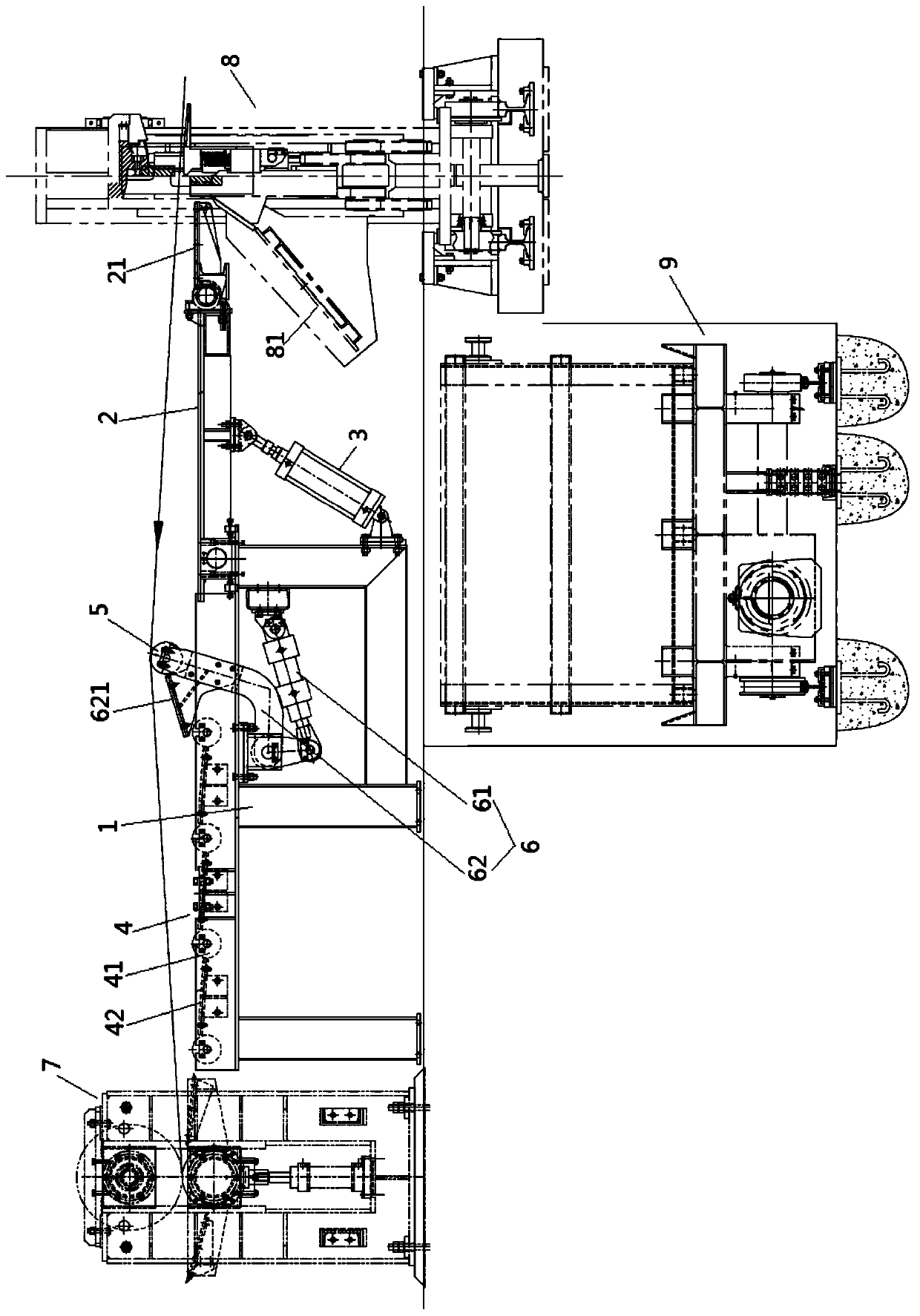

[0025] Example: such as Figures 1 to 3 As shown, the present embodiment provides a strip threading auxiliary device at the entrance of the continuous rolling mill. The entire strip threading auxiliary device is arranged on the steel strip pinch roller mechanism 7 distributed along the front and rear directions (the steel strip pinch roller mechanism 7 belongs to the continuous rolling mill. A part is between the prior art) and the hydraulic shear 8, wherein the belt threading auxiliary device includes a frame platform 1, and the above frame platform 1 is horizontally arranged between the steel strip pinch roller mechanism 7 and the hydraulic shear 8 along the front and rear direction; The guide plate 2, the above-mentioned guide plate 2 is hinged to the rear end of the above-mentioned frame platform 1; the swing driving mechanism 3, the above-mentioned swing drive mechanism 3 is connected with the above-mentioned guide plate 2, and can drive the above-mentioned guide plate 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com