Air leak detection method in air jet loom

An air-jet loom and leakage detection technology, which is applied to looms, liquid-tightness measurement using liquid/vacuum, textiles, etc., can solve problems such as expensive flow meters, inability to detect air leakage of air-jet looms, and poor air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

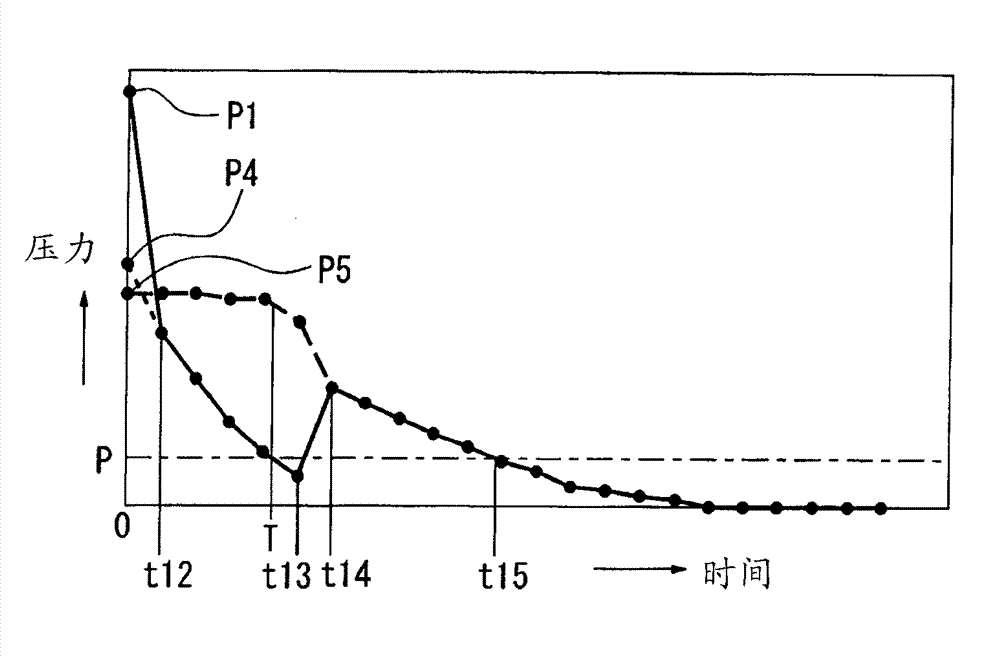

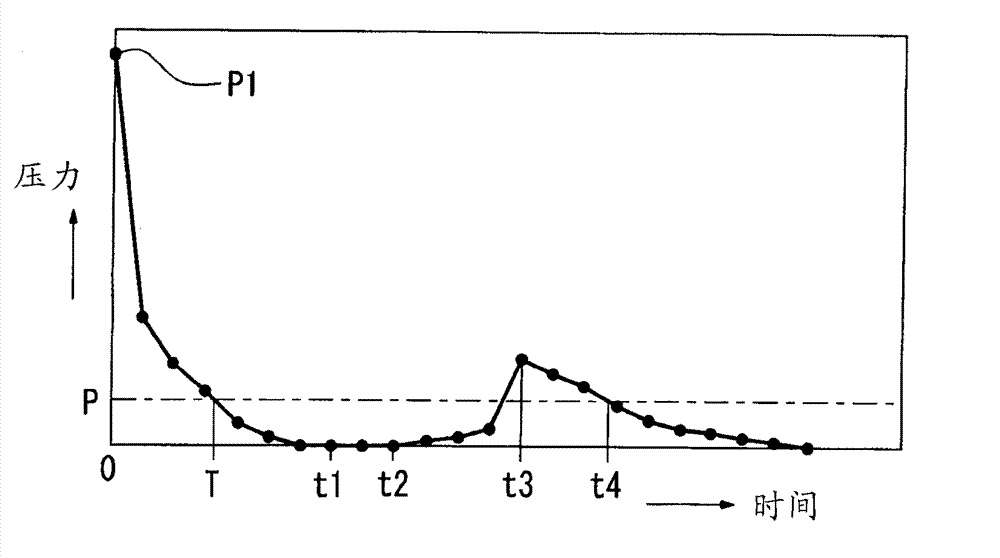

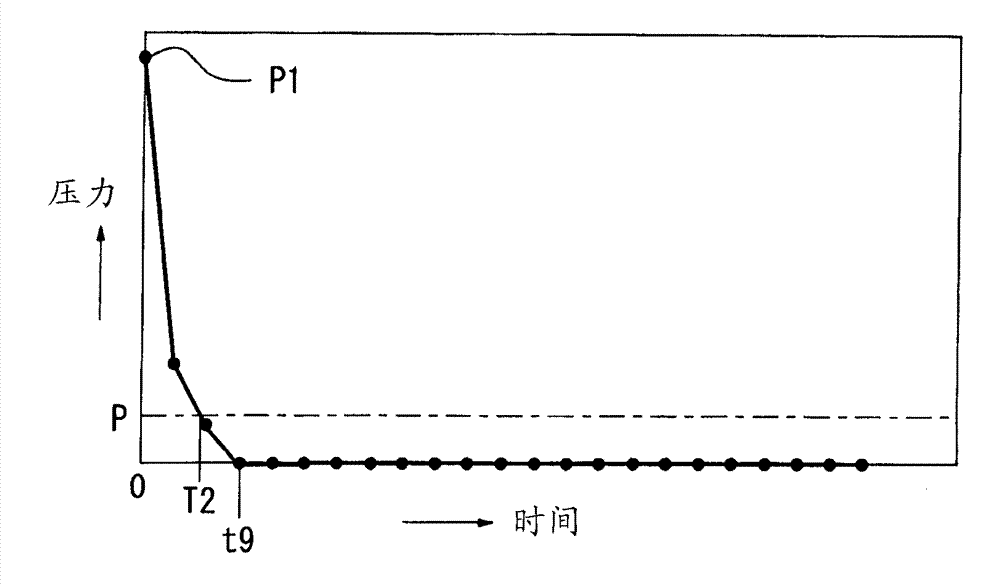

[0024] The following will refer to Figures 1 to 5C A first embodiment of the present invention is described. Reference is made to a schematic block diagram showing the weft insertion device of an air-jet loom figure 1 , the air supply source is indicated by reference numeral 1 and includes an air compressor (not shown) and a dryer (also not shown). Air supply source 1 via the corresponding conduit (in figure 1 Only one shown in and indicated by reference numeral 2) supplies compressed air to a plurality of air-jet looms, one of which is shown in figure 1 and is indicated by reference numeral 3 . The air supply source 1 and the air jet loom are placed in the weaving mill. Conduit 5 is connected to conduit 2 via a valve 4 that allows or stops the supply of compressed air.

[0025] A pressure gauge 7 is connected to the conduit 5 via a filter 6 for measuring the initial pressure P1 of the compressed air supplied from the air supply source 1 (cf. figure 2 ). The initial p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com