Rocker switch forcibly disconnected by rotating button cover

A rocker switch and button technology, applied in the direction of electrical components, etc., can solve problems such as arcing, high temperature, silver point sintering, etc., achieve the effect of wide application range, prevent equipment failure and safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

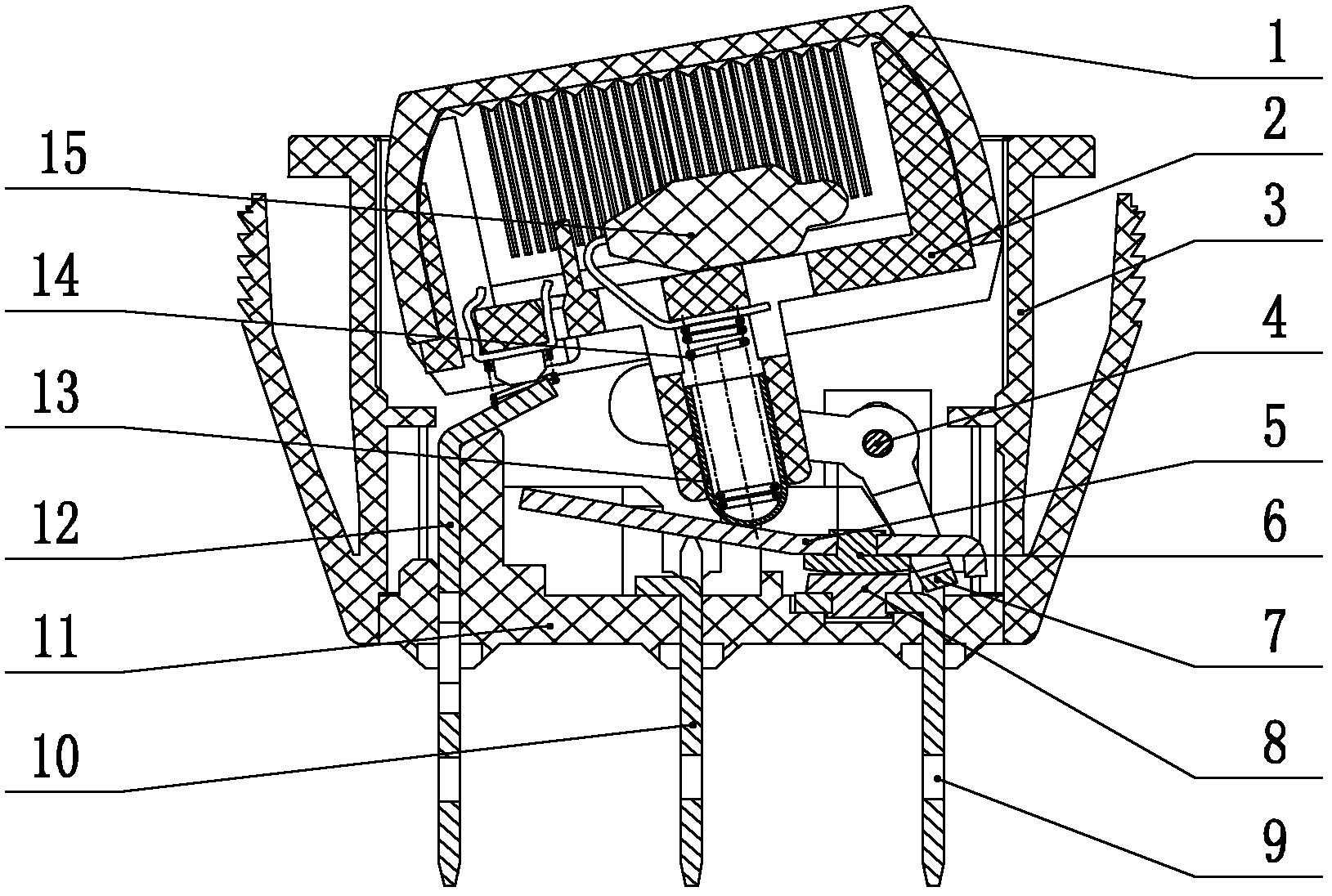

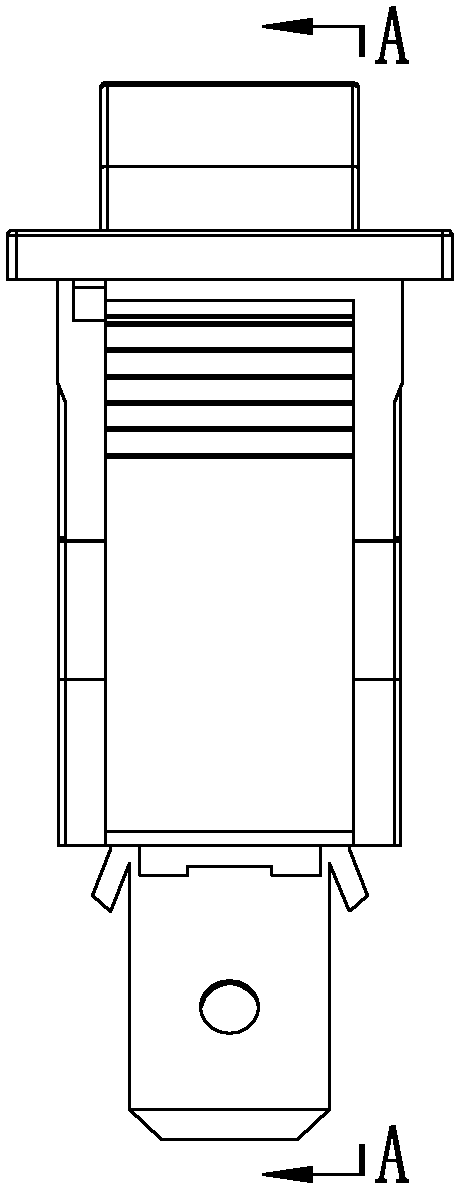

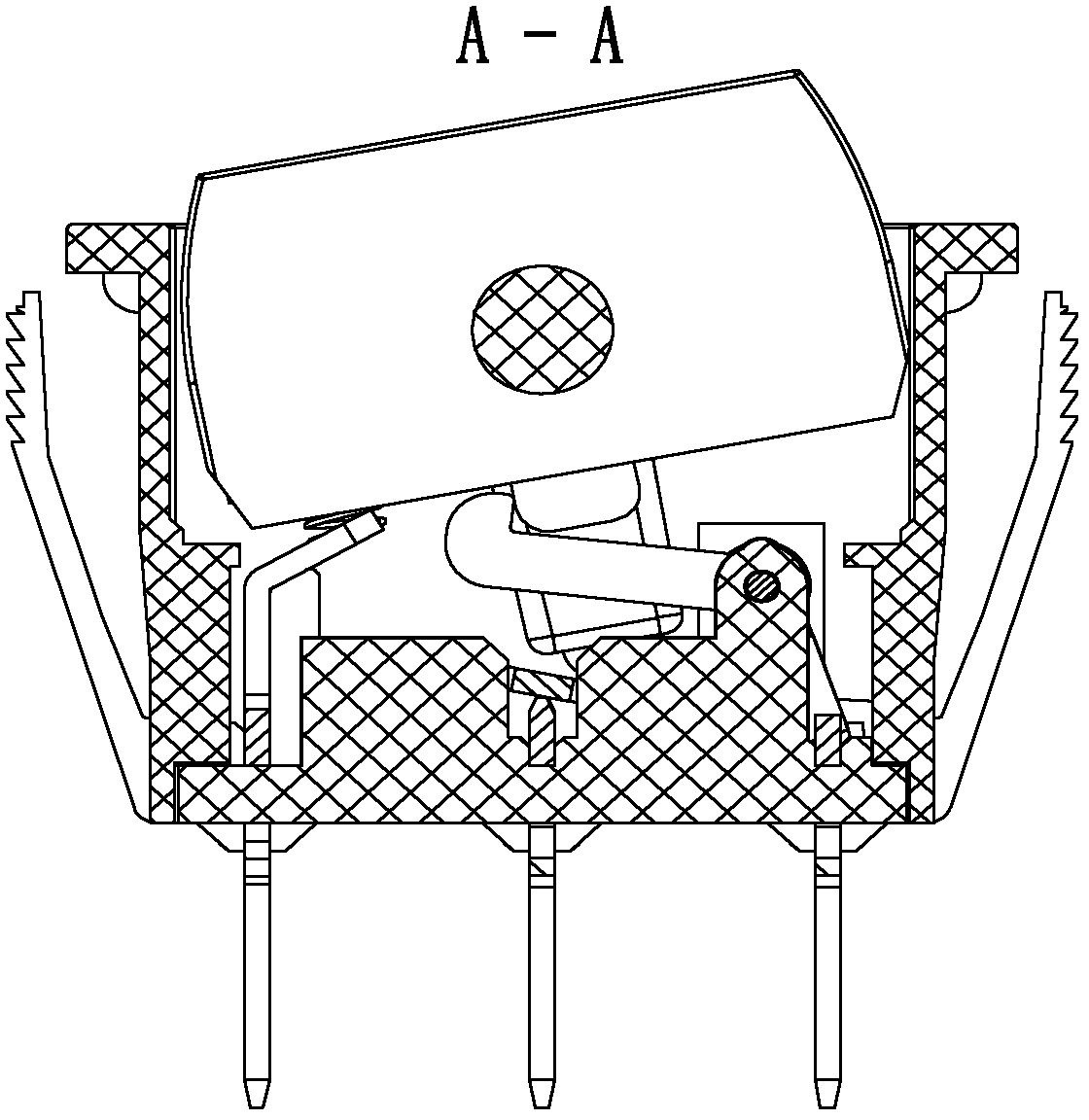

[0024] like Figure 1-3 , 5a, a rocker switch that is forced to disconnect when the button cover rotates. 7. Edge contact pin 9, static contact 8, middle contact pin 10, base 11, slide tube 13, spring 14, illuminant 15, the button cover 1 is covered on the button seat 2, the button cover 1 and the button The seat 2 is located in the shell 3, and the button seat 2 is provided with a sliding cylinder 13, the lower end of the sliding cylinder 13 touches the moving contact piece 5, and can slide on the moving contact piece 5, and the center of the forcing rod 7 is set on the On the rotating shaft 4, the forcing rod 7 can rotate on the rotating shaft 4. There is a boss below the button seat 2. One end of the forcing rod 7 is connected to the button seat 2, and is closely matched with the boss below the button seat 2. The contact pieces 5 are in clearance fit, the movable contact 6 is arranged on the movable contact piece 5, and can move up and down with the movable contact piece, ...

Embodiment 2

[0028] like Figure 4b As shown, the top of the exposed part of the button cover is a V-shaped surface, and the middle movable part of the button cover part adopts a steel ball structure, such as Figure 5b shown. All the other are with embodiment 1.

Embodiment 3

[0030] like Figure 4c As shown in , the top of the exposed part of the button cover is a curved surface. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com