Drum-type washing machine

A drum type washing machine, drum technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of difficulty in obtaining cleaning effect, inability to spray washing water, difficulty in spraying washing water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

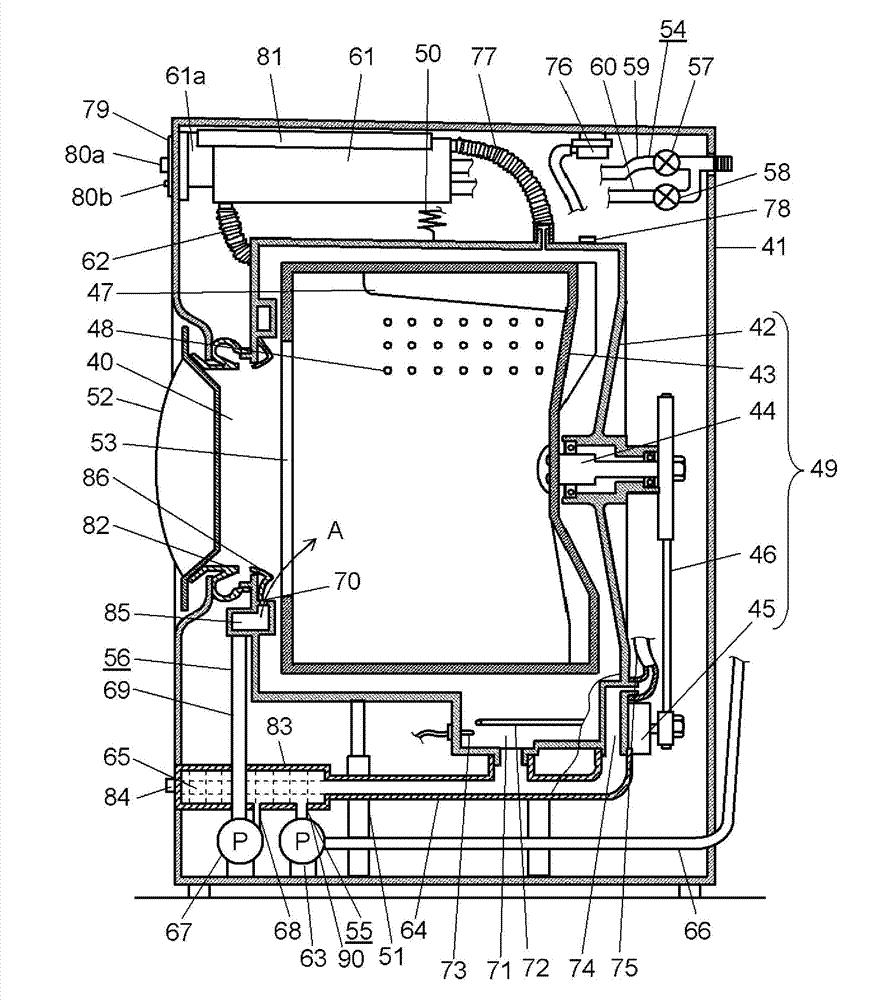

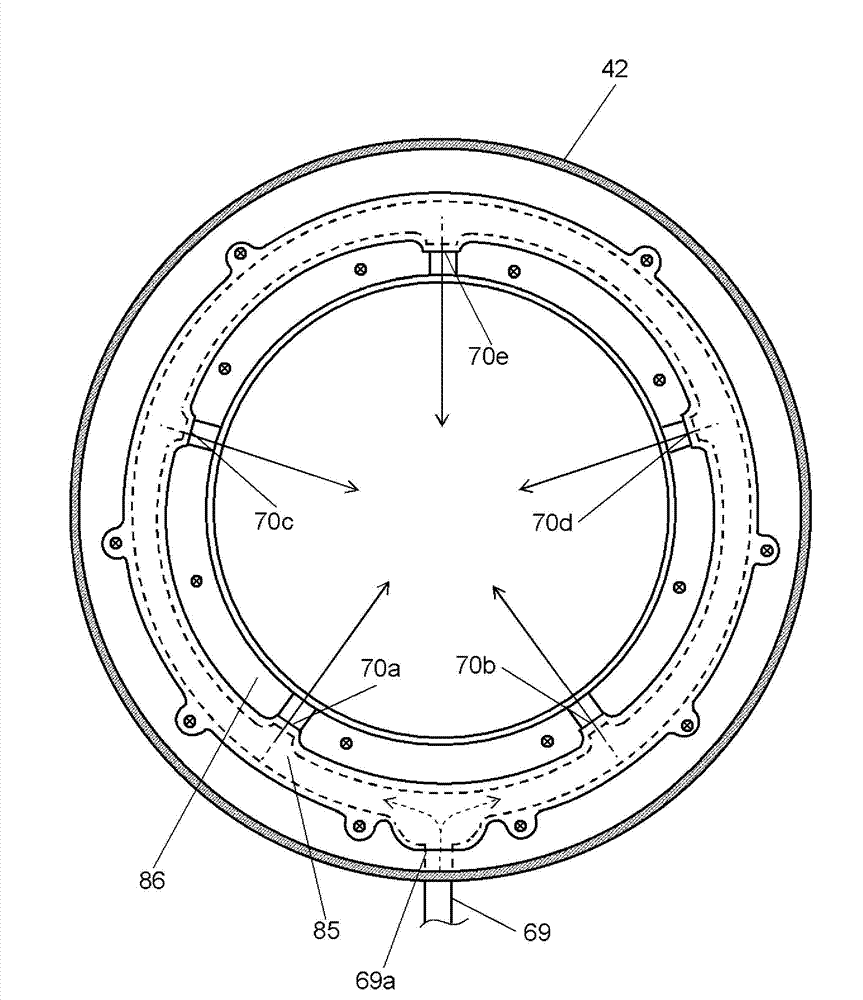

[0021] figure 1 It is a sectional view of the front-loading-type washing machine in embodiment of this invention.

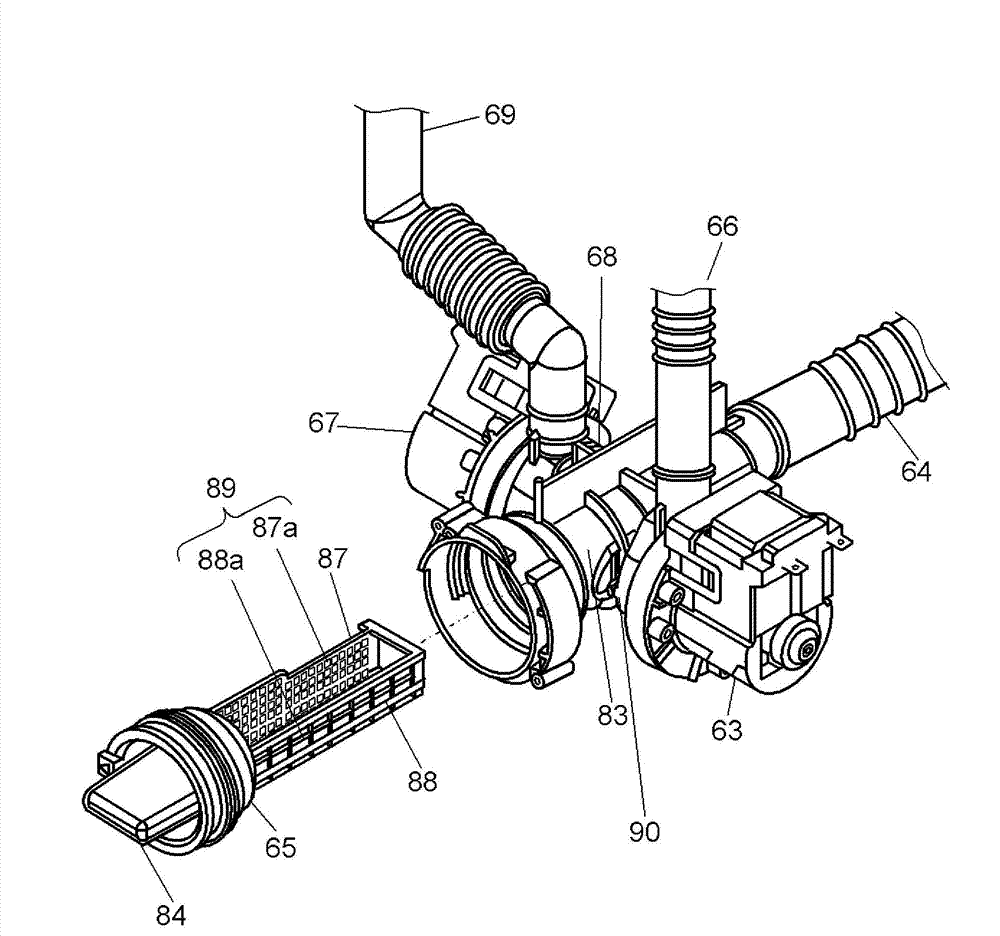

[0022] Such as figure 1 As shown, the front-loading washing machine of this embodiment includes a rotating drum 43, a water tank 42, a motor 45, a filter housing 83 communicated with the water tank 42, a circulation pump 67 communicated with the filter housing 83, and a The flow path 85, the discharge port 70 and the control device 81.

[0023] The water tank 42 is provided inside the main body 41 so that it can swing freely, and the rotating drum 43 is provided inside the water tank 42 so that it can rotate freely. Further, the rotary drum 43 is driven to rotate in the forward rotation and the reverse direction around the rotation shaft 44 which is connected to the motor 45 mounted on the lower part of the back side of the water tank 42 through the belt 46 and rotates in the horizontal direction. The center axis of rotation set on.

[0024] The inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com