Low-torque linkage double-open fire hydrant

A low-torque, fire hydrant technology, used in fire rescue and other directions, can solve problems such as unfavorable safe use of fire hydrants, large opening torque, resonance, etc., to achieve the effect of eliminating resonance, eliminating noise, and light and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which exemplary embodiments of the invention are illustrated. In the drawings, the same reference numerals denote the same or similar components or elements.

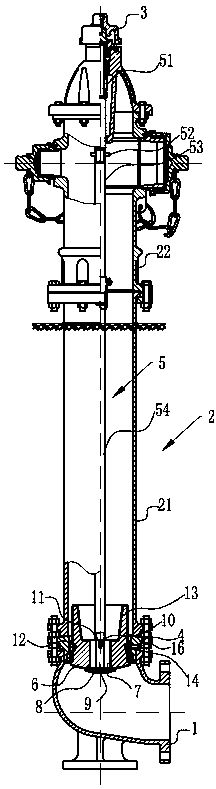

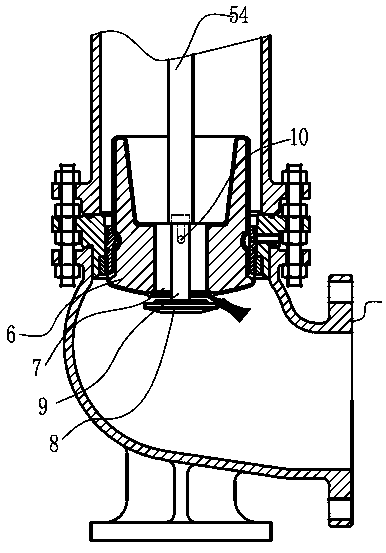

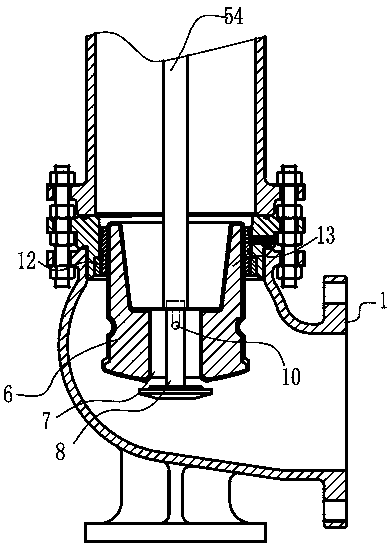

[0024] Such as figure 1 As shown, the low-torque linkage double-opening fire hydrant includes a bolt seat 1, a bolt body 2 is installed on the bolt seat 1, and a bolt cover 3 is packaged at the end of the bolt body 2, and the bolt seat 1 and the bolt A valve seat 4 is provided between the body 2, a valve cavity is provided in the valve seat 4, a valve core is provided in the valve cavity, an operating rod 5 is provided through the plug body 2 and the plug cover 3, the The valve core includes a valve plate 6 for blocking the valve cavity, and the valve plate 6 is provided with a pressure relief hole 7, and the area of the pressure relief hole 7 is one-sixth of the area of the valve plate 6 to one-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com