Roll changing template and roll changing positioning method for straightening machine

A positioning method and technology for straightening rolls, applied in the field of metallurgy, can solve the problems of spline tooth collision, misalignment, damage, etc., to reduce roll change time, improve work efficiency, and simplify the roll change preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

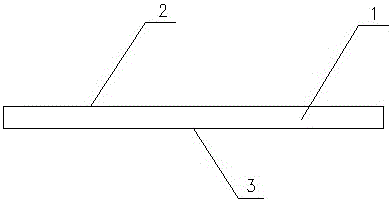

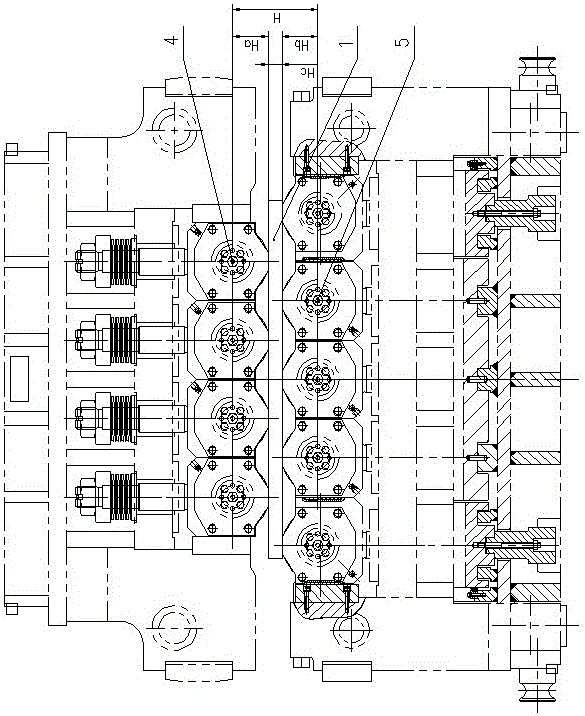

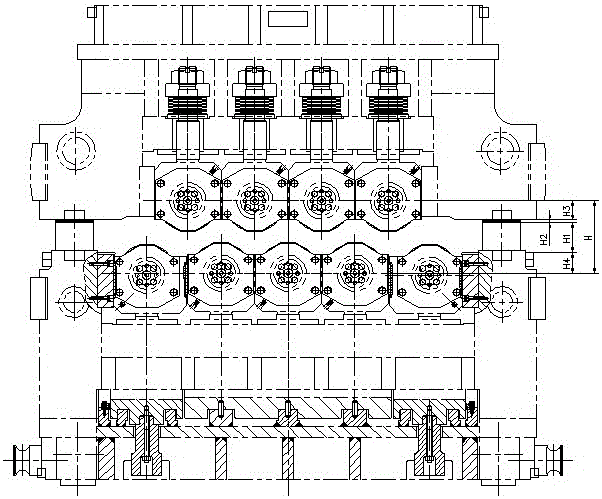

[0016] figure 2 It is a schematic diagram of the installation and positioning of the present invention. As shown in the figure, a method for positioning a roll changer of a leveler according to the present invention includes placing two roll change templates 1 on both sides of the leveler (transmission side and operation side) respectively. Between the upper straightening roller bearing seat 4 and the lower straightening roller bearing seat 5, the upper straightening roller bearing seat 4 is pressed against the lower straightening roller bearing seat 5 through the roll changing template 1, and the selected roller changing template 1 Thickness Hc=L-Ha-Hb, the center-to-center distance L between the upper straightening roller bearing housing 4 and the lower straightening roller bearing housing 5 is the center-to-center distance H between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com