Injection molding machine

A technology of injection molding machine and body, which is applied in the field of injection molding devices, can solve problems such as safety accidents, safety doors not installed, and inconvenient unloading of injection molding products, and achieve the effects of improving safety, improving work efficiency, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

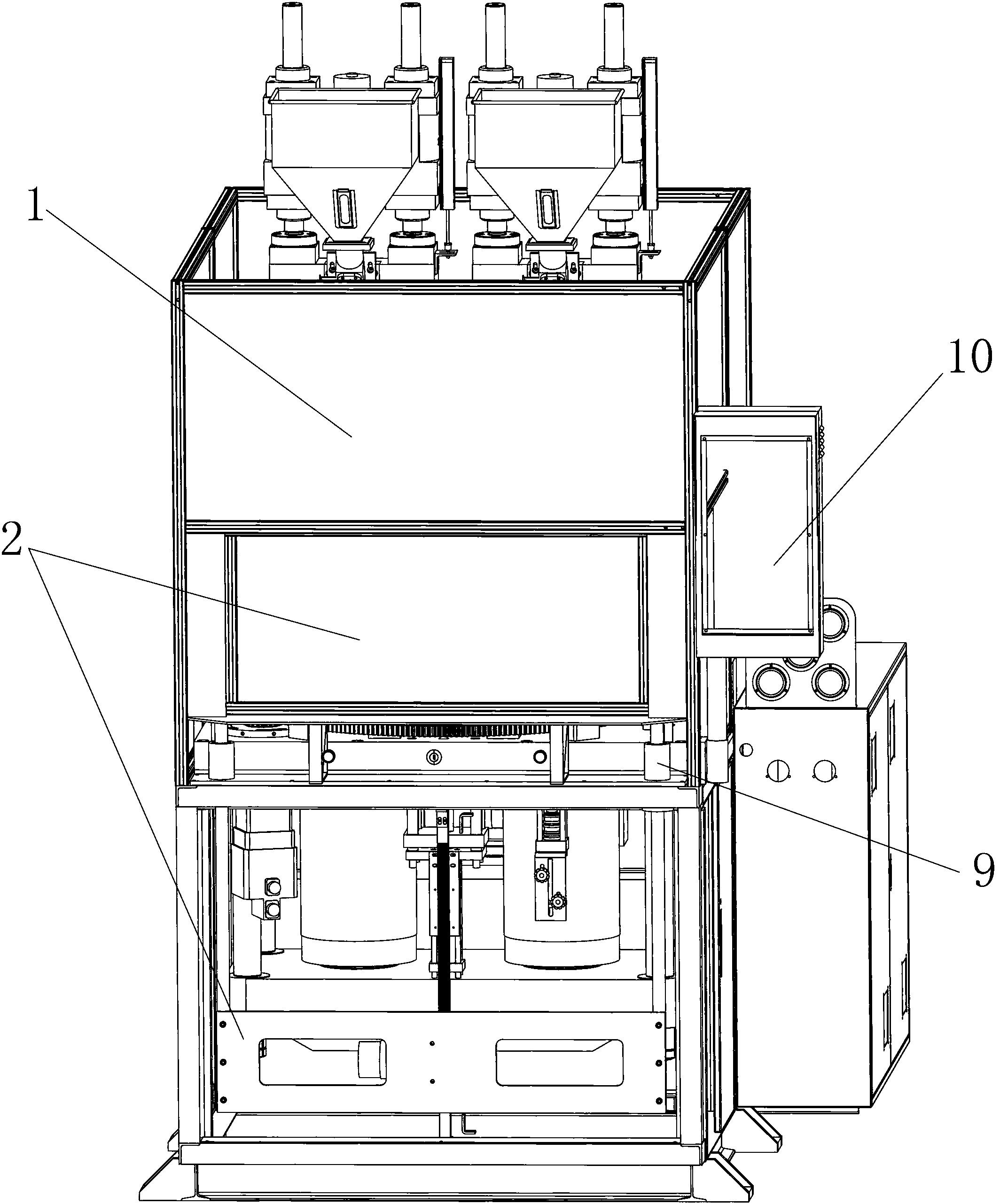

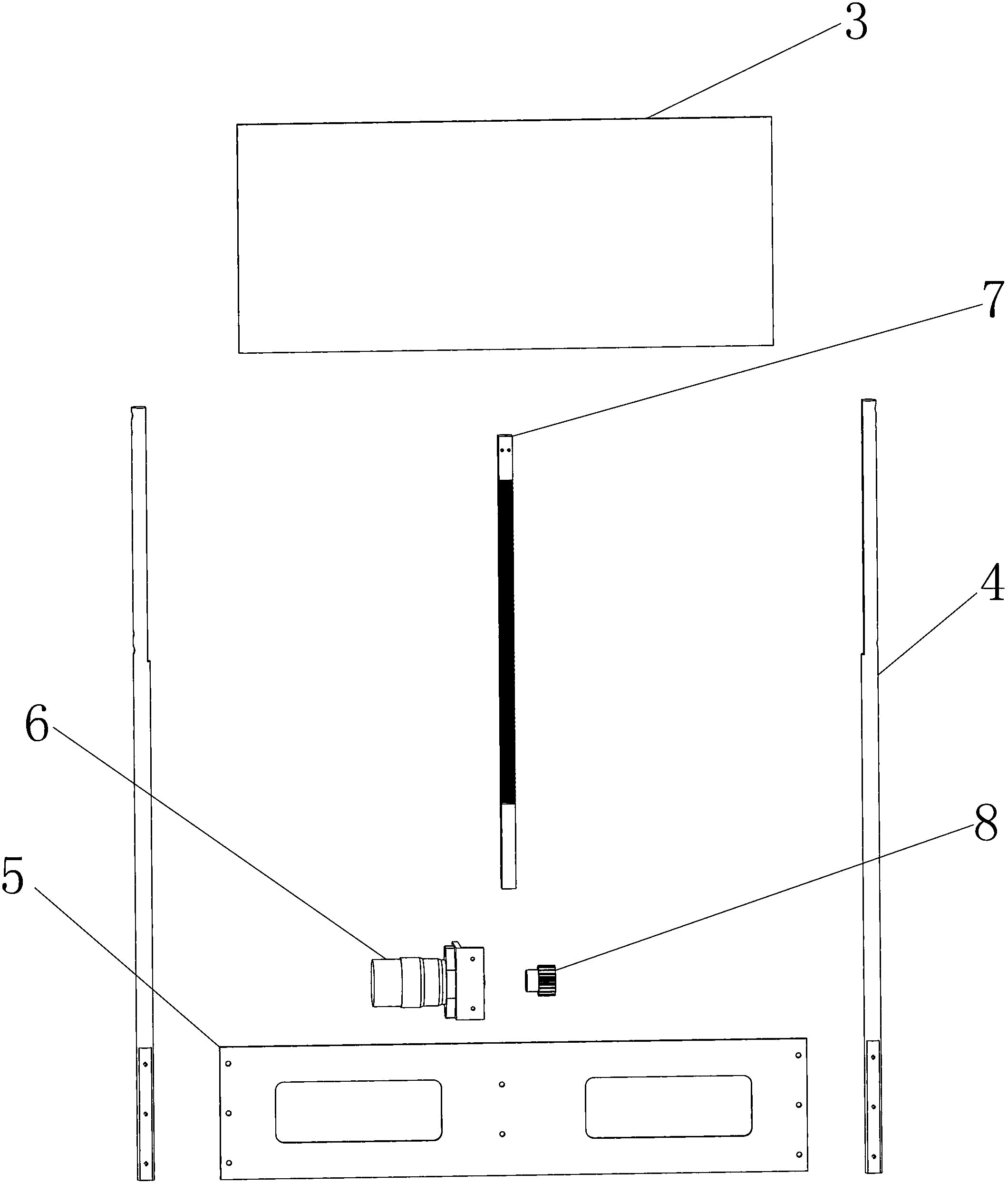

[0014] Example: such as Figures 1 to 2 As shown, the injection molding machine of the present invention includes an injection molding machine body 1, wherein a semi-automatic safety door device 2 is arranged on the above-mentioned injection molding machine body 1, and a controller 10 is installed on the above-mentioned injection molding machine body 1, and the above-mentioned controller 10 controls the semi-automatic safety door The device 2 moves up and down; the semi-automatic safety door device 2 includes a safety door 3, a lifting column 4, a lifting plate 5, a lifting motor 6 and a rack 7; the valve 3 is fixedly connected to the lifting column 4; the lifting column 4 is connected to the injection molding machine body 1 Sleeve fit, the lower end of the lifting column 4 is fixedly connected with the lifting plate 5; the lifting motor 6 is assembled on the lifting plate 5, and the lifting motor 6 is provided with a gear 8; the rack 7 is installed on the body 1 of the injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com