Production method of brominated butadiene styrene rubber

A production method and technology of bromide, which are applied in the field of flame retardants, can solve the problems of insufficient substitution of hexabromocyclododecane, toxic environmental effects of aquatic plants, and lack of thermal stability to prevent application, and achieve environmental protection of production technology, The effect of high product yield and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

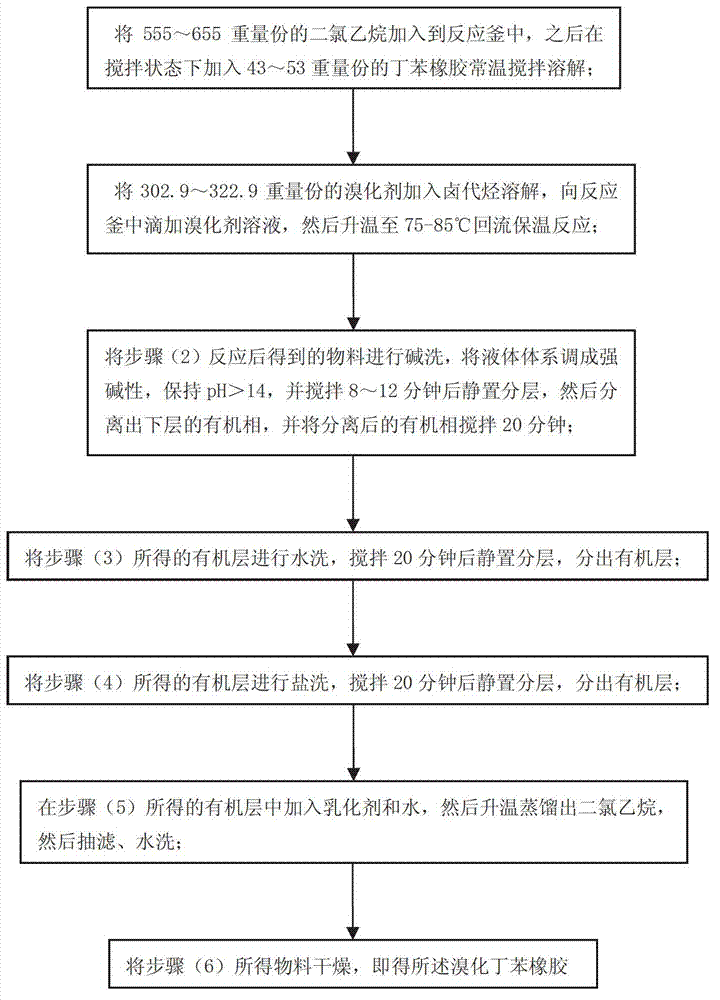

Method used

Image

Examples

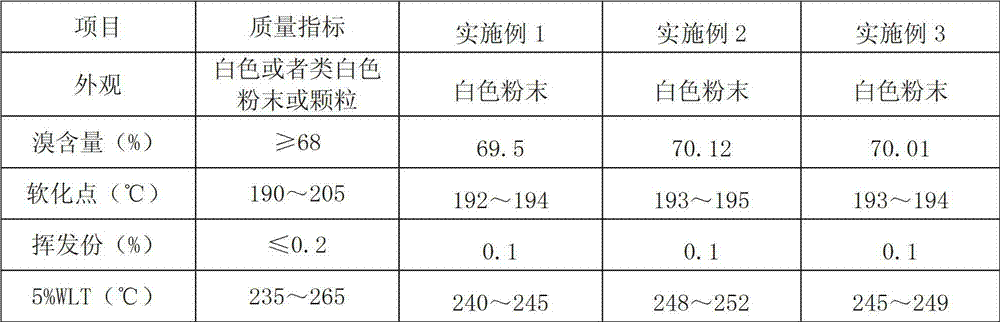

Embodiment 1

[0041] Put 555kg of dichloroethane into a 1000L reactor, turn on the mixer, add 48kg of styrene-butadiene rubber into the reactor under stirring, and stir at room temperature for 35 minutes to dissolve it completely.

[0042] Add 302.9 kg of tetrabutylammonium tribromide (dissolved in dichloroethane) dropwise to the reactor, and control the temperature at 40°C during the dropwise addition process, and the rate of addition can be controlled depending on the temperature.

[0043] The temperature was raised to 80°C, and the reaction was kept under reflux for 17 hours.

[0044] Alkali washing: transfer the material to the neutralization kettle, add 180kg of sodium bisulfite solution with a mass concentration of 20%, stir for 8 minutes, let stand to separate layers, and the pH value is >14.

[0045] Water washing: transfer the lower organic phase to a water washing kettle, add 180kg of water, stir for 20 minutes, wash with water, and let stand to separate layers.

[0046] Salt was...

Embodiment 2

[0051] Put 605kg of dichloroethane into a 1000L reactor, turn on the mixer, add 48kg of styrene-butadiene rubber into the reactor under stirring, stir at room temperature for 40 minutes, and dissolve it completely.

[0052] Add 350kg of bromosuccinimide (dissolved in dichloroethane) dropwise to the reaction kettle, and control the temperature at 50°C during the dropwise addition process, and the rate of addition can be controlled depending on the temperature.

[0053] The temperature was raised to 80°C, and the reaction was kept under reflux for 15 hours.

[0054] Alkali washing: transfer the material to the neutralization kettle, add 200kg of sodium bisulfite solution with a mass concentration of 20% (40kg of sodium bisulfite dissolved in 160kg of water), stir for 10 minutes, let stand to separate layers, and the pH value is > 14 .

[0055] Water washing: transfer the lower organic phase to a water washing kettle, add 200kg of water, stir for 20 minutes, wash with water, and...

Embodiment 3

[0061] Put 655kg of dichloroethane into a 1000L reactor, turn on the mixer, add 48kg of styrene-butadiene rubber into the reactor under stirring, stir at room temperature for 35 minutes, and dissolve it completely.

[0062] Add 305 kg tetrabromocyclone (dissolved in dichloroethane) dropwise to the reaction kettle, and control the temperature at 45°C during the dropwise addition process, and the rate of addition can be controlled depending on the temperature.

[0063] The temperature was raised to 80°C, and the reaction was kept under reflux for 20 hours.

[0064] Alkali washing: transfer the material to the neutralization kettle, add 220kg of sodium bisulfite solution with a mass concentration of 20%, stir for 12 minutes, let stand to separate layers, and the pH value is >14.

[0065] Water washing: transfer the lower organic phase to a water washing tank, add 220kg of water, stir for 20 minutes, wash with water, and let stand to separate layers.

[0066] Salt wash: transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com