Hydraulic center rotary joint

A central rotary joint, hydraulic technology, applied in the direction of load hanging components, earthmovers/shovels, construction, etc., can solve problems such as oil circuit obstruction, influence of rotary body and rotary shaft, and easy leakage of rotary joint oil. , to achieve the effect of reducing labor intensity, improving applicability and ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

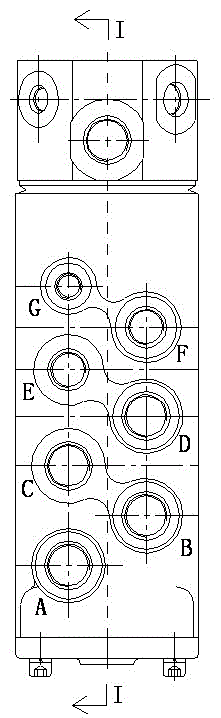

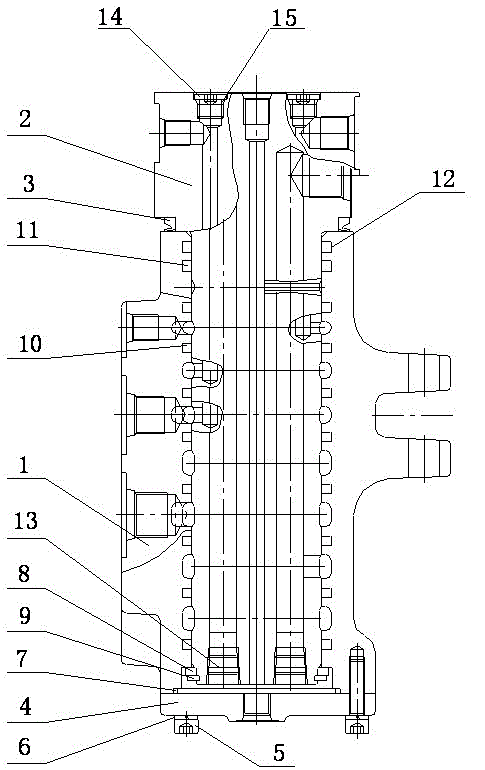

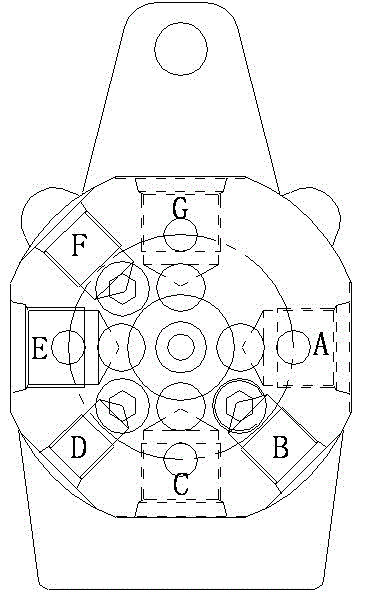

[0019] see Figure 1 to Figure 5 , the present invention relates to a hydraulic central rotary joint, comprising a rotary body 1 and a rotary shaft 2, the lower end of the rotary shaft 2 is axially inserted into the rotary body 1 from the upper end of the rotary body 1, and the upper end of the rotary shaft 2 is exposed to the rotary shaft body 1, a water sealing ring 3 is provided between the upper end of the rotating body 1 and the rotating shaft 2, the water sealing ring 3 is used to prevent gas from leaking or entering, the lower end of the rotating shaft 2 and the lower end of the rotating body 1 Horizontally aligned, the lower end of the revolving body 1 is provided with an end cover 4, and the end cover 4 is fixed on the lower end of the revolving body 1 through bolts 5 and flat washers 6, and the lower end of the revolving body 1 and the end cover 4 are provided with O-ring I7, a retaining ring 8 and a shaft elastic retaining ring 9 are provided between the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com