Corner connecting device for rod-shaped supporting members in rest stand

A corner connection and support member technology, applied in the direction of rod connection, connection member, mechanical equipment, etc., can solve the problems of limited adaptability and inability to disassemble the shelf, and achieve strong material handling capacity, light weight, and flexible structure. changing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention are described with reference to the above drawings.

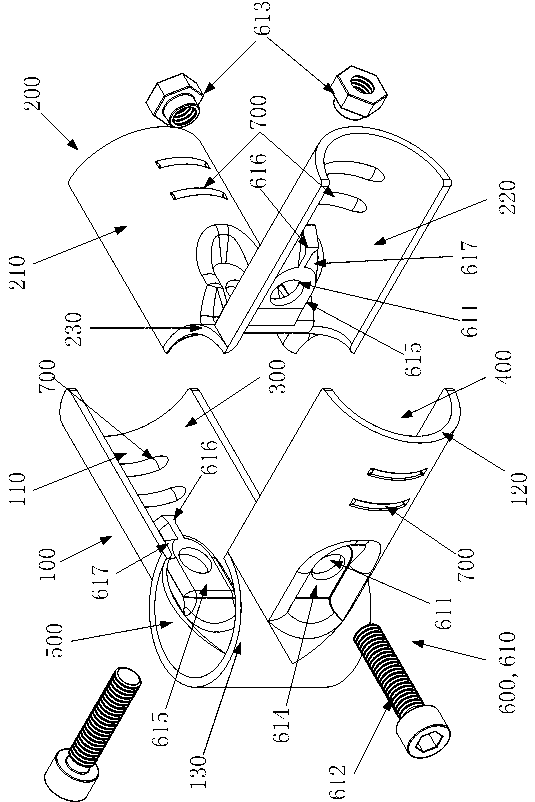

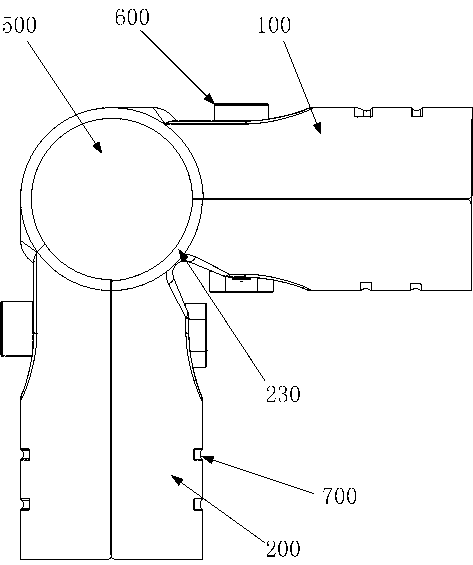

[0010] Depend on figure 1 and figure 2 As can be seen in the figure, the corner connecting device of the rod-shaped support member in the shelf includes an upper fastener 100 and a lower fastener 200 that are fastened to each other, and the upper fastener 100 includes a first fastener 110 that is partially tubular, The second fastener 120 and the third fastener 130 connected therebetween, the axes of the first fastener 110, the second fastener 120 and the second fastener 130 are perpendicular to each other, and the lower fastener 200 includes Part tubular fourth fastener 210, fifth fastener 220 and sixth fastener 230 connecting them, the axes of the fourth fastener 210, fifth fastener 220 and sixth fastener 230 are perpendicular to each other, so The first fastener 110 is fastened with the fourth fastener 210 to form a hollow first tunnel 300, the second fastener 120 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com