Gear shifting mechanism of manual transmission

A technology of manual transmission and shifting mechanism, which is applied to instruments, controlled components, mechanical equipment, etc., can solve the problems of complex shifting process, and achieve the effect of simplifying shifting process, reducing wear and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

[0045] A shift mechanism for a manual transmission, comprising:

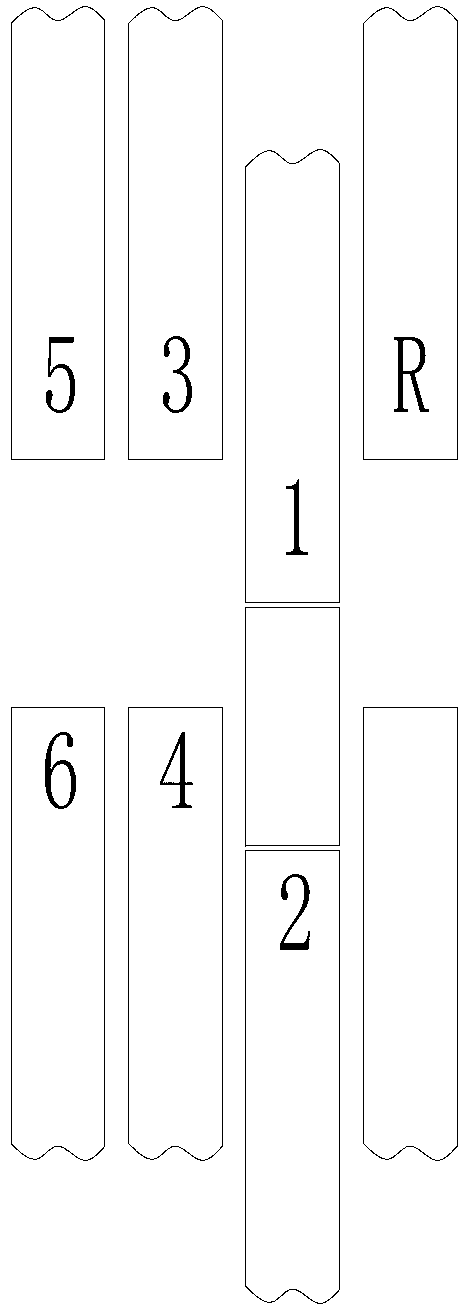

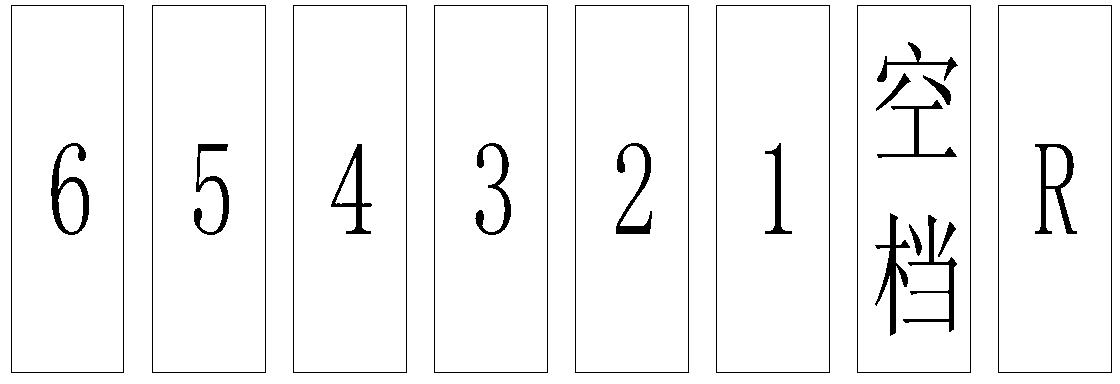

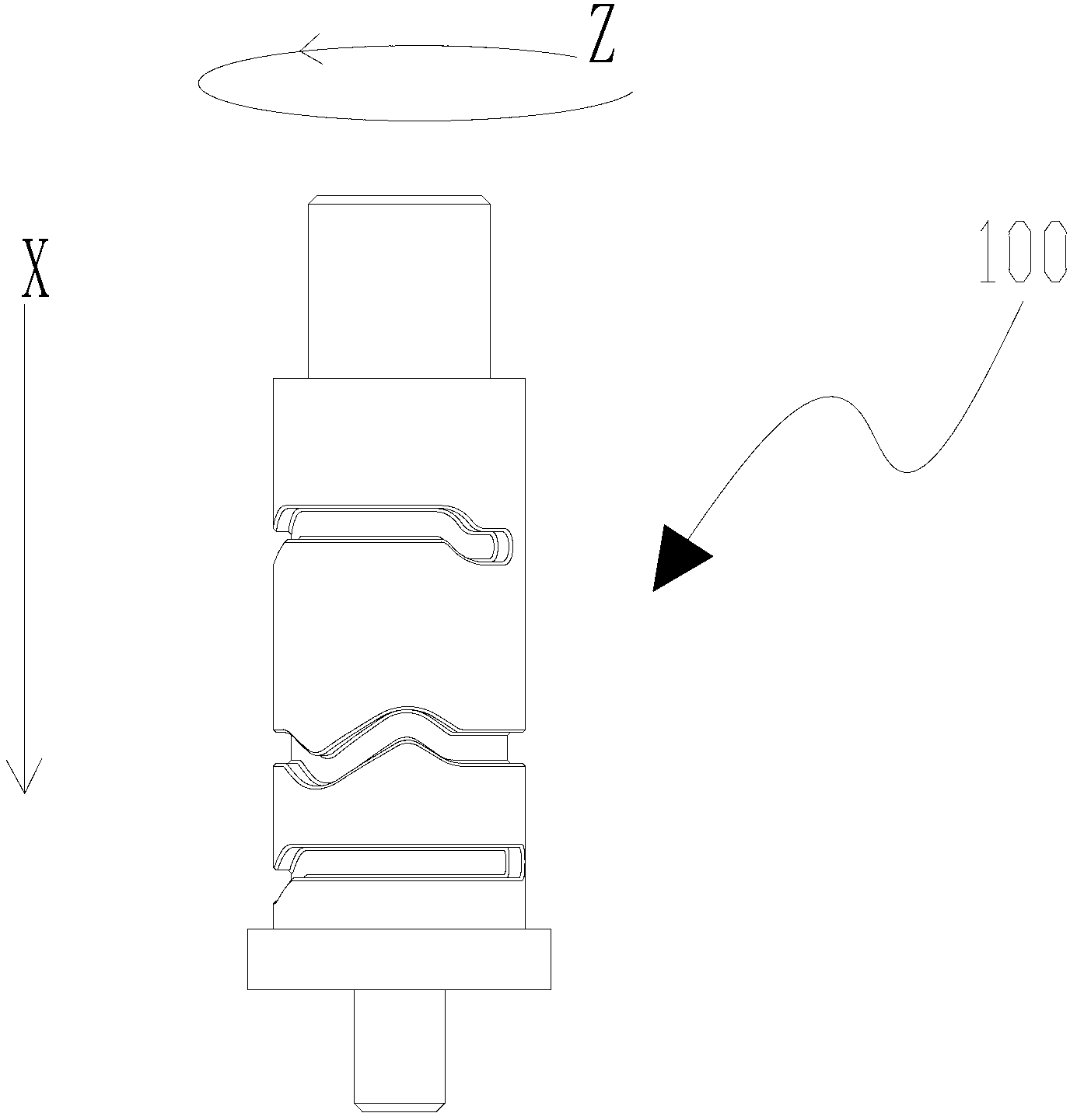

[0046] like image 3 The shift drum 100 shown, the top of the shift drum 100 is connected as Figure 4 The crank and rocker mechanism 500 is shown, the crank and rocker mechanism 500 drives the shift drum 100 to rotate, and the crank and rocker mechanism 500 is composed of a crank 501 and a rocker 502; the support surface 102 is located on the shift drum 100 bottom end, the shift drum 100 passes through as Image 6 The self-lubricating bearing 600 shown is connected to the transmission housing 200, thereby reducing the friction between the shift drum 100 and the transmission housing 200, thereby effectively reducing the thrust required to push the gear lever and reducing the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com