Electric vehicle gear shift control system and control method thereof

A technology for electric vehicles and control systems, applied in transmission control, control devices, vehicle components, etc., can solve the problems of high system cost, complex control process, low service life, etc., and achieve simple shifting process, good reliability, The effect of improving the ride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

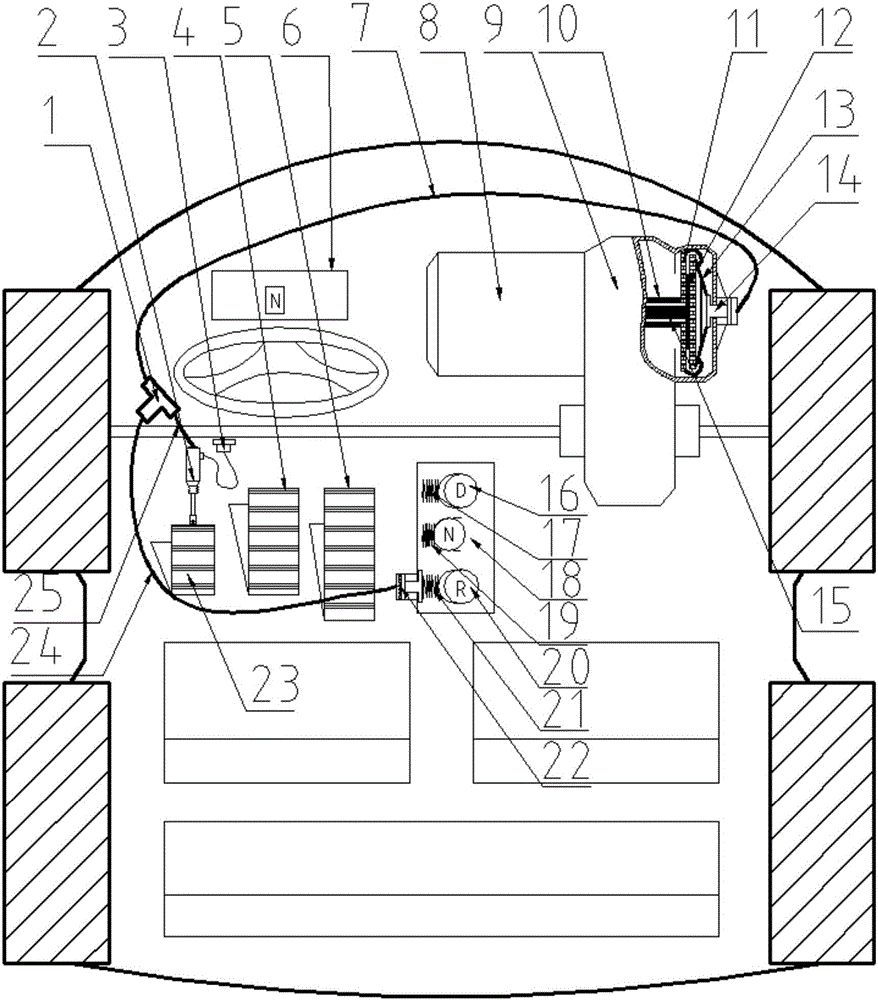

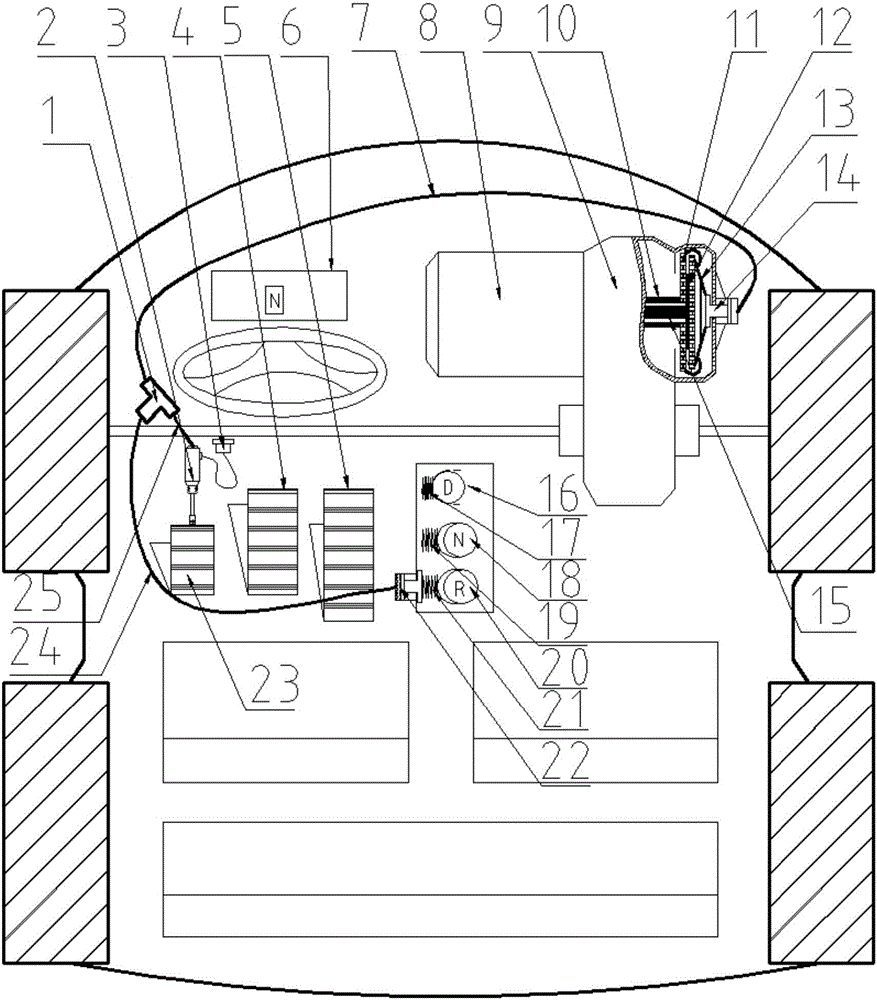

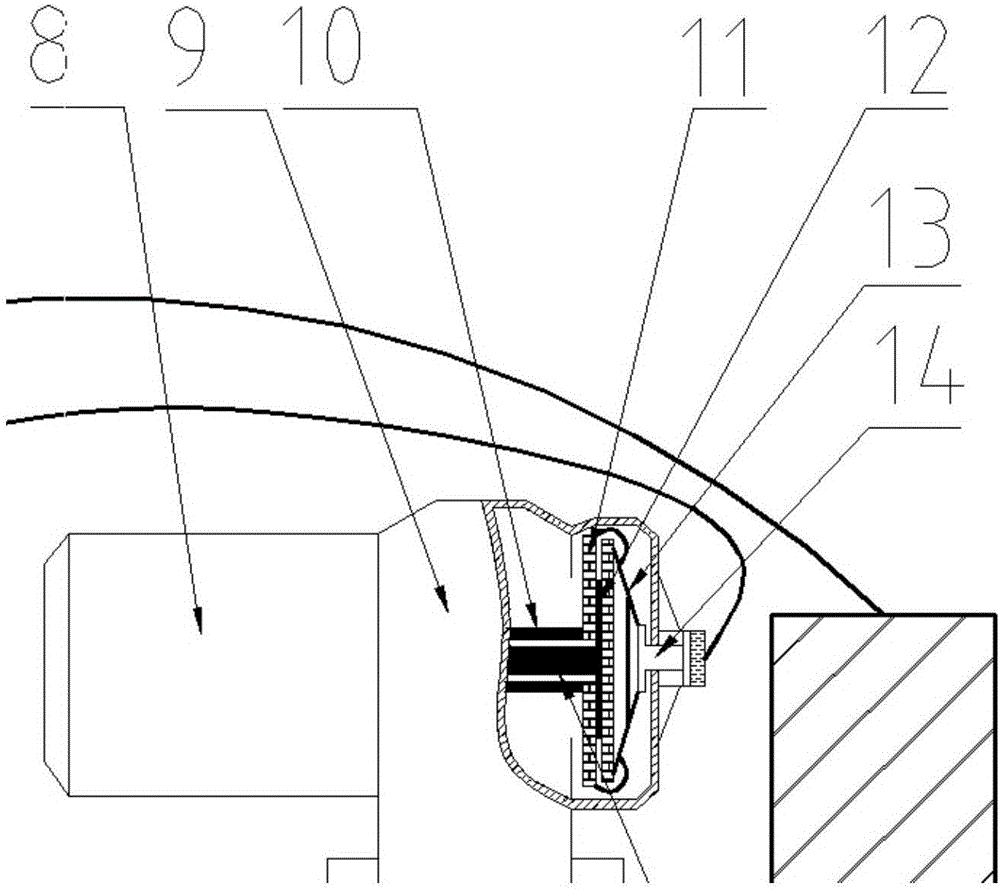

[0066] Such as figure 1 As shown, the present invention provides a gear shift control system for an electric vehicle, which is composed of a gear shift operating device and a hydraulic shift action transmission device. Described shift operation device is made up of shift pedal 23, shift rocker arm 26, return coil spring 27, guide rod 28, roller 29 and guide track 30. The hydraulic shift action transmission device is composed of the first oil pipe 7 and the hydraulic release bearing 14; in addition, the shift control system of the electric vehicle also includes an anti-mislocking reverse gear device, which is composed of the second oil pipe 24, the hydraulic cylinder 22 , a hydraulic master cylinder 2, an oil pot 3 and a third oil pipe 25;

[0067] The first oil pipe 7 , the second oil pipe 24 and the third oil pipe 25 are connected through the tee 1 . The oil outlet of the hydraulic master cylinder 2 is connected with the third oil pipe 25, the piston rod end of the hydrauli...

Embodiment 2

[0085] Such as Figure 11 As shown, on the basis of the shift control system described in the above-mentioned embodiment 1, a cable-type shift action transmission device can also be used as the shift action transmission device. , a fork type release bearing 32, a release rocker arm 33 and a release fork 34;

[0086] Such as Figure 12a with Figure 12b As shown, the release shift fork 34 is hinged in the two casting ears of the gearbox 9 housing, and can rotate around the casting ear axis, and at the same time, the release shifting fork end presses the release bearing 32 to move along its axial direction. The separation rocker arm 33 is connected with the shaft end of the separation shift fork 34 by spline transmission, so that the separation shift fork 34 also rotates when the separation rocker arm 33 swings. The two ends of the outer casing of the control cable 31 are respectively fixed on the car body and the gearbox casing, and the two ends of the inner steel wire of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com