Shaft-pin-type force sensor and method for detecting radial force stressed on shaft pin

A force sensor and radial force technology, applied in the sensor field to achieve high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

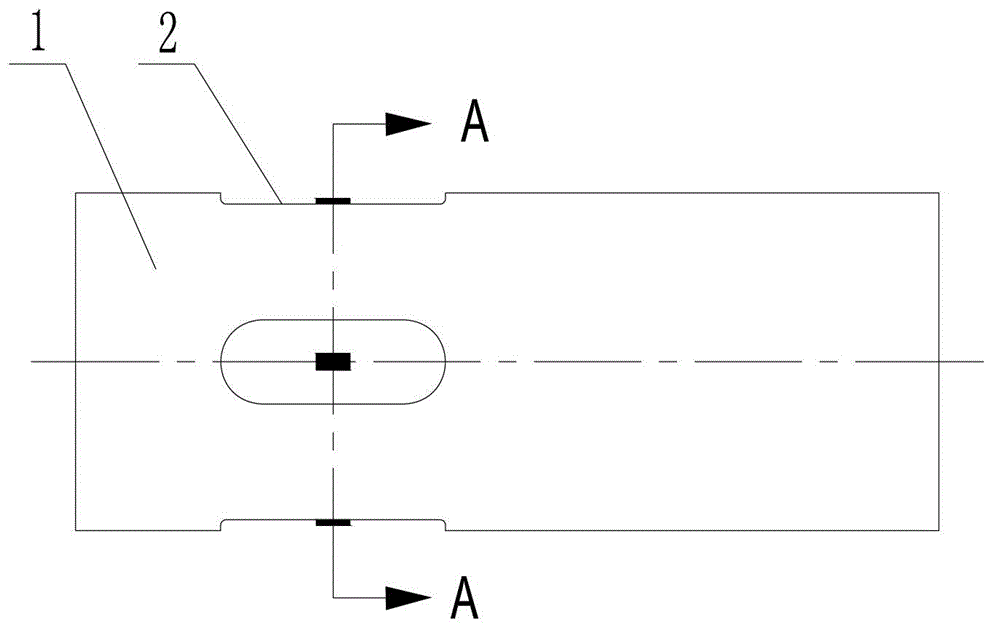

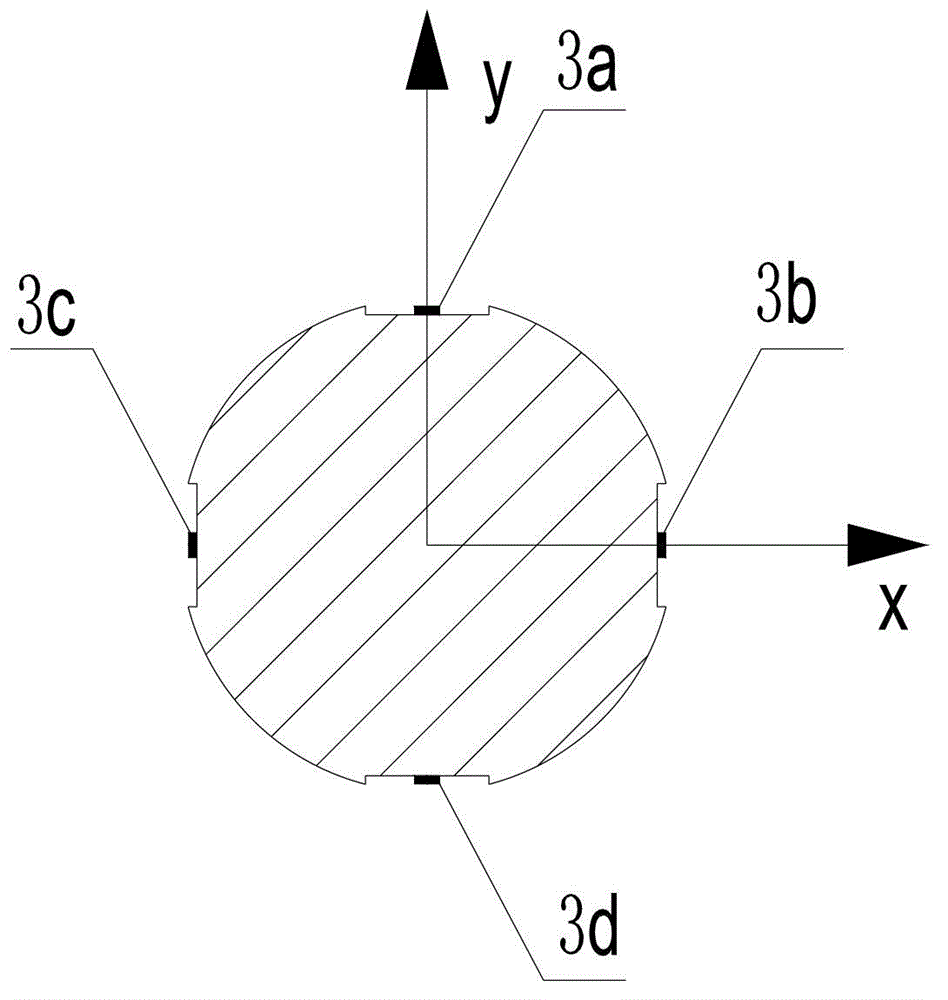

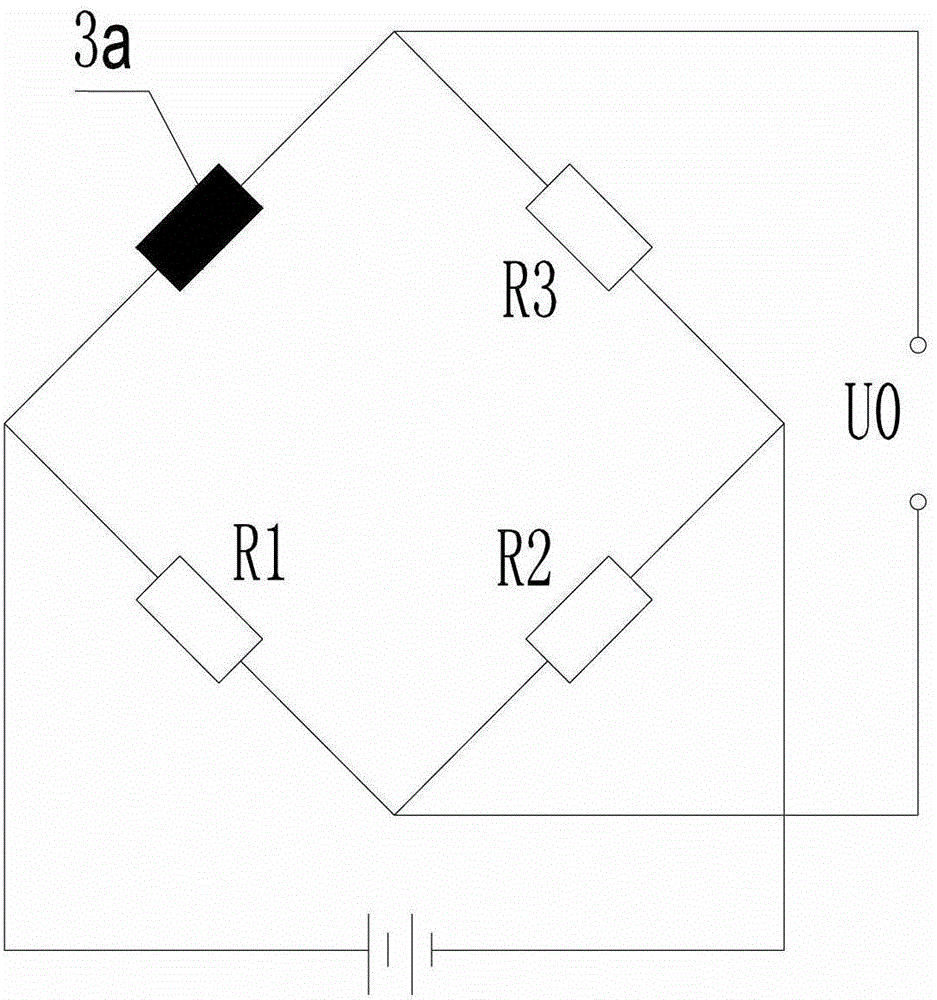

[0025] Combine below Figure 1 to Figure 3 , The preferred embodiment of the present invention will be further described in detail. Such as figure 1 with figure 2 As shown, a shaft pin sensor includes a shaft pin 1 and four strain gauges 3a, 3b, 3c, 3d, and the four strain gauges are evenly arranged in the same circumferential direction of the shaft pin. The four strain gauges 3a, 3b, 3c, and 3d are pasted in the four grooves 2 through a pasting process. The groove 2 is square, and the two ends adopt a semi-circular transition structure. The groove 2 structure can prevent the stress concentration at the groove 2 when the shaft pin 1 is elastically deformed, resulting in the measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com