Natural sea cucumber and processing method thereof

A processing method and sea cucumber technology, applied in the sea cucumber and its processing field, can solve the problems of loss of water-soluble substances of nutrients, inelasticity, etc., and achieve the effects of rich and delicate meat texture, strong elasticity and toughness, and a simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Take 1kg of live sea cucumbers collected from the sea, remove their viscera and spouts and clean them. Then place it in a constant temperature water bath at 40°C and heat for 2 hours. Put the above sea cucumber hydrolyzed by autolysozyme into 100° C. water and boil for 0.5 hour. Carry out vacuum nitrogen-filling packaging to the sea cucumbers that have been sterilized and deenzyme above, that is, use a fully automatic continuous vacuum packaging machine to evacuate, and simultaneously use a KY-2N nitrogen analyzer to fill nitrogen with 0.2 atmospheres for 1.1 seconds. Then place the packaging bag at -35°C for quick freezing for 40 minutes, take it out and freeze it at -18°C for storage, and place the obtained live sea cucumber in a vacuum nitrogen-filled package, undergo constant temperature hydrolysis with sea cucumber autolysin and then kill the enzyme, and then quickly freeze the live sea cucumber. It is the original sea cucumber.

example 2

[0019] Take 1kg of live sea cucumbers collected from the sea, remove their viscera and spouts and clean them. Then place it in a constant temperature water bath at 60°C and heat for 0.5 hours. Put the above sea cucumber hydrolyzed by autolysozyme into 100°C water and boil for 2 hours. Carry out vacuum nitrogen-filling packing to the sea cucumbers that have been deenzyme-killed and sterilized above, that is, use a full-automatic continuous vacuum packaging machine to evacuate, and simultaneously fill nitrogen with 0.2 atmospheric pressure for 1.0 second by a KY-2N nitrogen analyzer. Then place the packaging bag at -38°C for quick freezing for 20 minutes, take it out and freeze it at -20°C for storage, and place the obtained live sea cucumber in a vacuum nitrogen-filled package, undergo constant temperature hydrolysis with sea cucumber autolysin and then kill the enzyme, and then quickly freeze the live sea cucumber. It is the original sea cucumber.

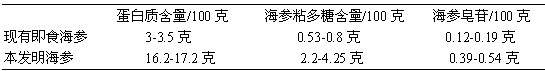

[0020] Product of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com