Shifting shaft structure of motorcycle

A technology for shifting shafts and motorcycles, which is applied to bicycle gear transmission mechanisms, bicycle accessories, transportation and packaging, etc. It can solve the problems of inflexible shifting and slow return of shift arms, and achieve flexible shifting and return The effect of easy and flexible scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

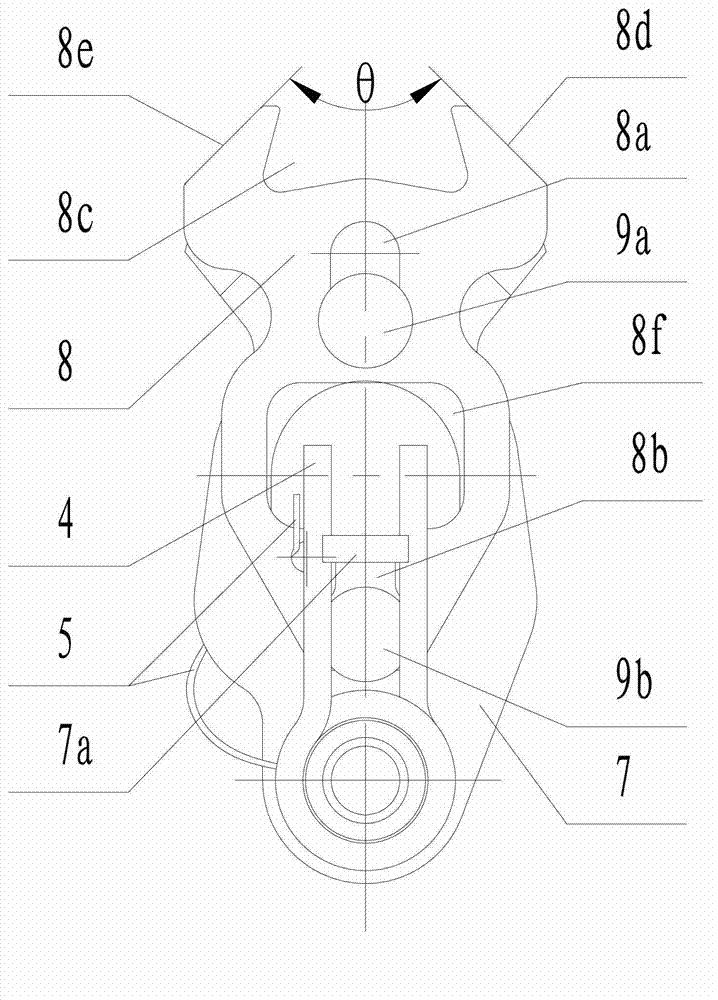

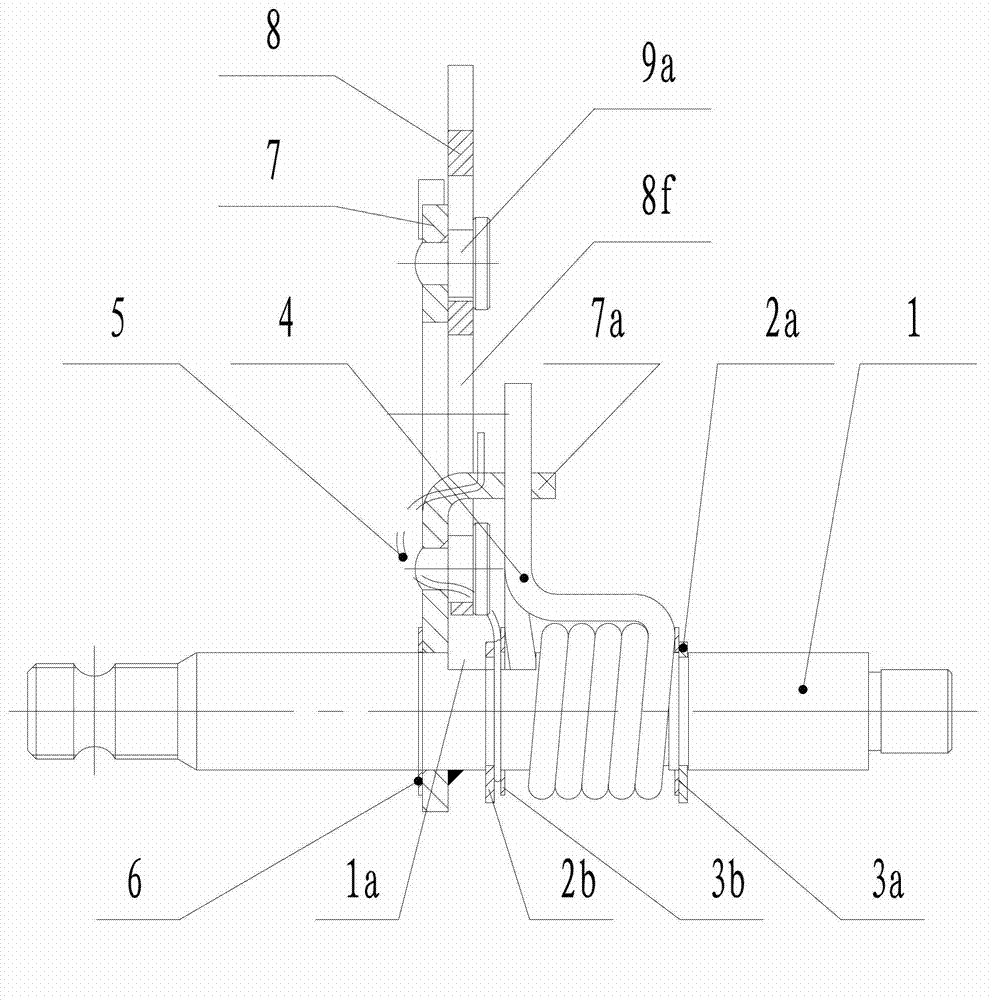

[0025] Such as Figure 1 to Figure 3 As shown, a motorcycle shift shaft structure includes a shift shaft 1 on which a first retaining ring 2a and a second retaining ring 2b are arranged at intervals. The shift shaft 1 is provided with a first flat pad 3a and a second flat pad 3b inside the first retaining ring 2a and the second retaining ring 2b, and the shift shaft is fitted between the first flat pad 3a and the second flat pad 3b There are torsion springs 4.

[0026] The middle part of the shift shaft 1 is provided with a square groove 1a, and the first retaining ring 2a and the first flat pad 1b are arranged at the square groove 1a.

[0027] The shift shaft 1 is welded with a fixed dial 7 close to the square groove 1a, and a shift shaft washer 6 is arranged on the side of the fixed dial 7 away from the square groove 1a.

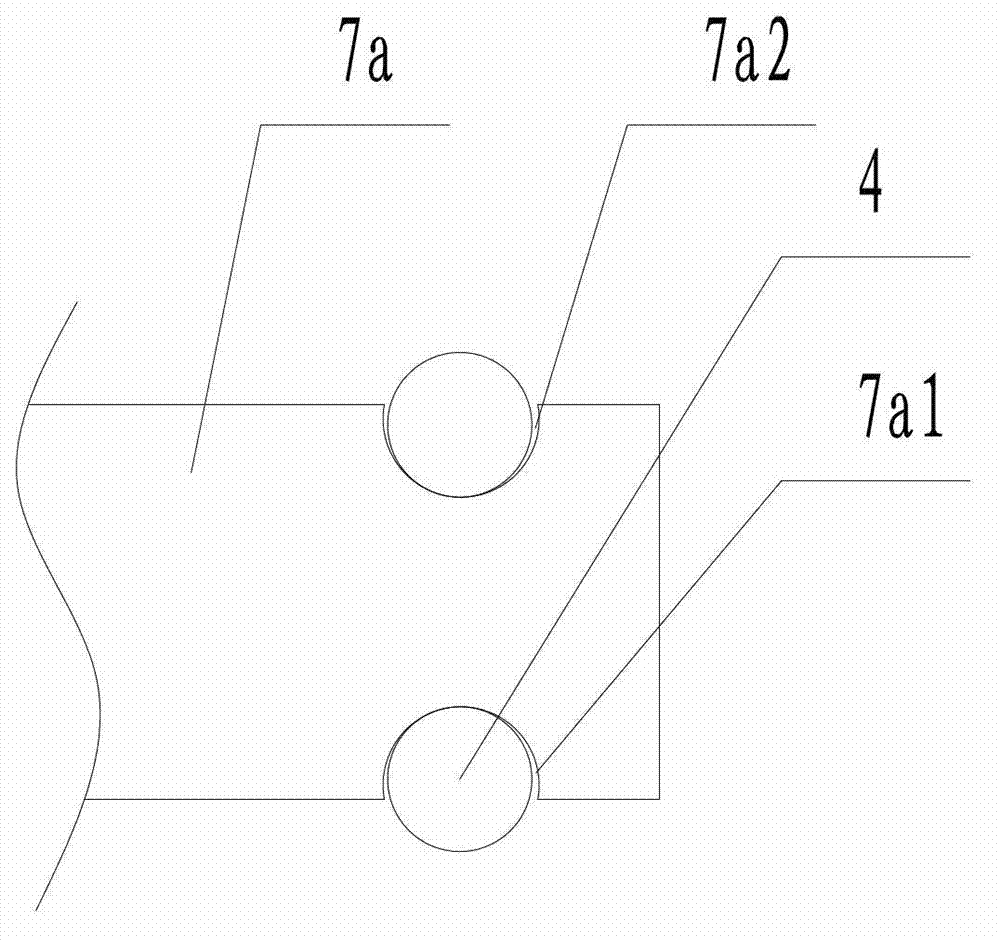

[0028] The fixed dial 7 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com