Active energy ray-curable inkjet ink composition

一种活性能量射线、喷墨油墨的技术,应用在油墨、复制/标记方法、印刷等方向,能够解决吐出油墨困难、粘度高等问题,达到低粘度、射出特性优异、高颜色再现性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Hereinafter, the present invention is further described in detail through examples, but the following examples do not limit the scope of rights of the present invention in any way. In addition, "part" in an Example means a "weight part."

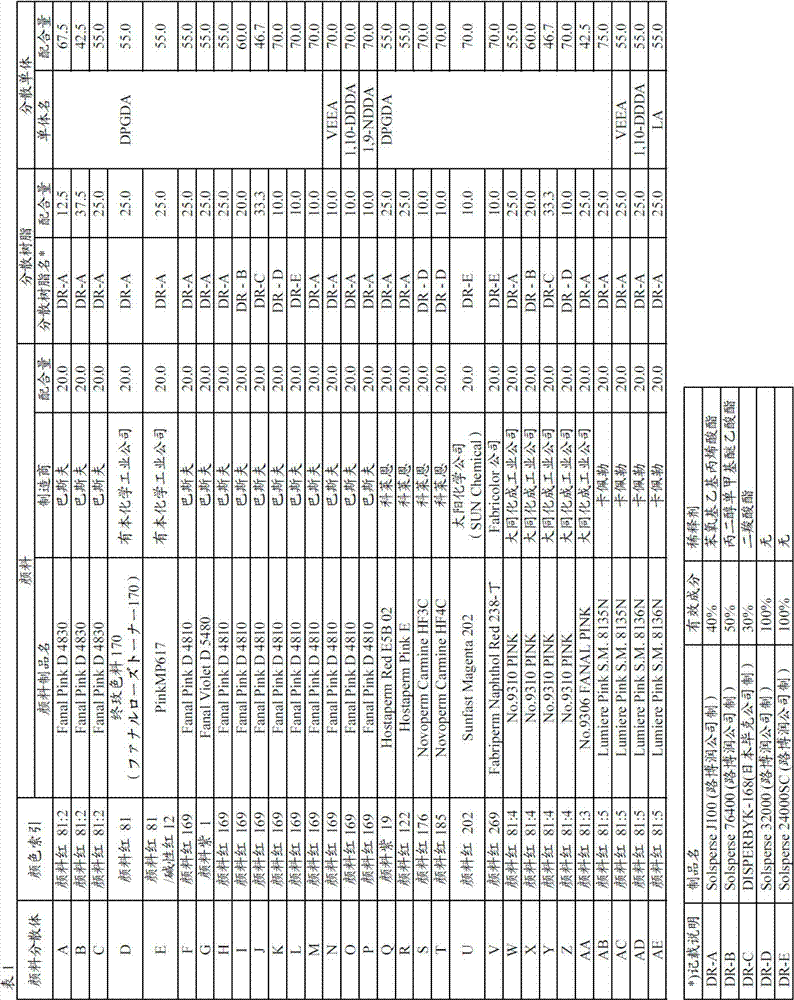

[0059] (Preparation of Pigment Dispersion)

[0060] As described in Table 1, after mixing pigments, dispersing resins (resin-based pigment dispersants) and monomers, disperse them with a bead-type disperser (DCP mill) for 1 hour to obtain pigment dispersions A~AE. Dispersion was performed using Zr beads of a diameter of 0.3 mm at a volume filling rate of 75%.

[0061] In addition, the description of the dispersion resin used is described below in Table 1. DR-A, DR-B and DR-C are dispersion resins having a urethane skeleton, and DR-D and DR-E are polyesteramine-based Disperse resin.

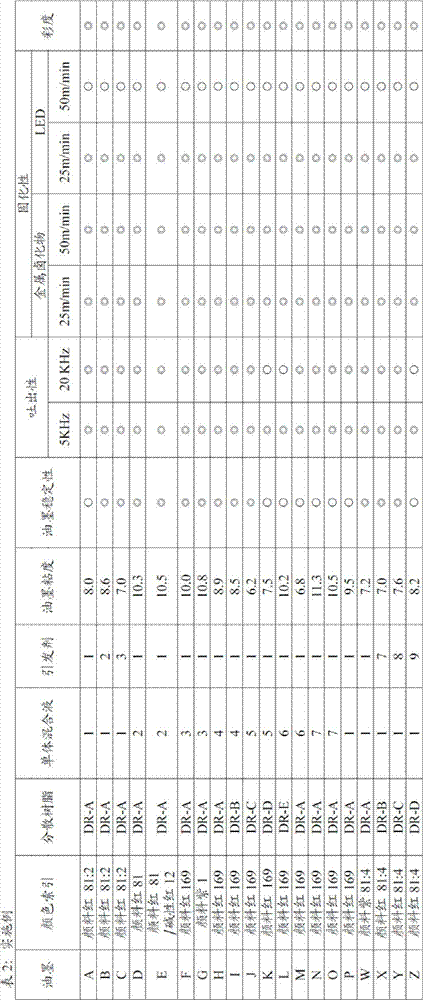

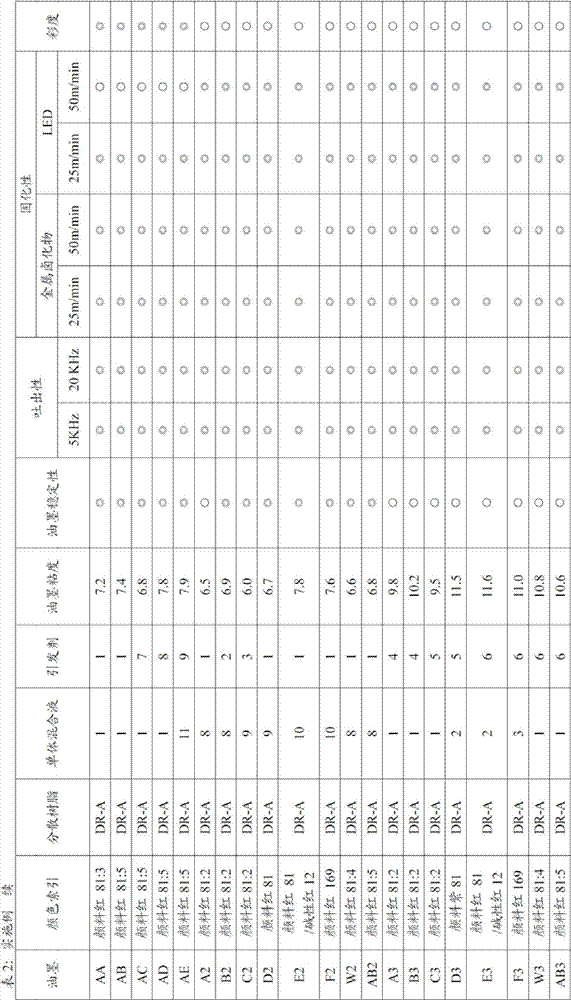

[0062] (preparation of ink)

[0063] As shown in Table 2 and Table 3, the monomer mixed liquid was slowly added to 20 parts of each obtained pigment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com