High pressure reduction-oxidation desulfurization process

A process and oxidizer technology, applied in the direction of absorption purification/separation, chemical instruments and methods, separation methods, etc., can solve problems such as foaming, poor quality, lower overall process economy and process operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

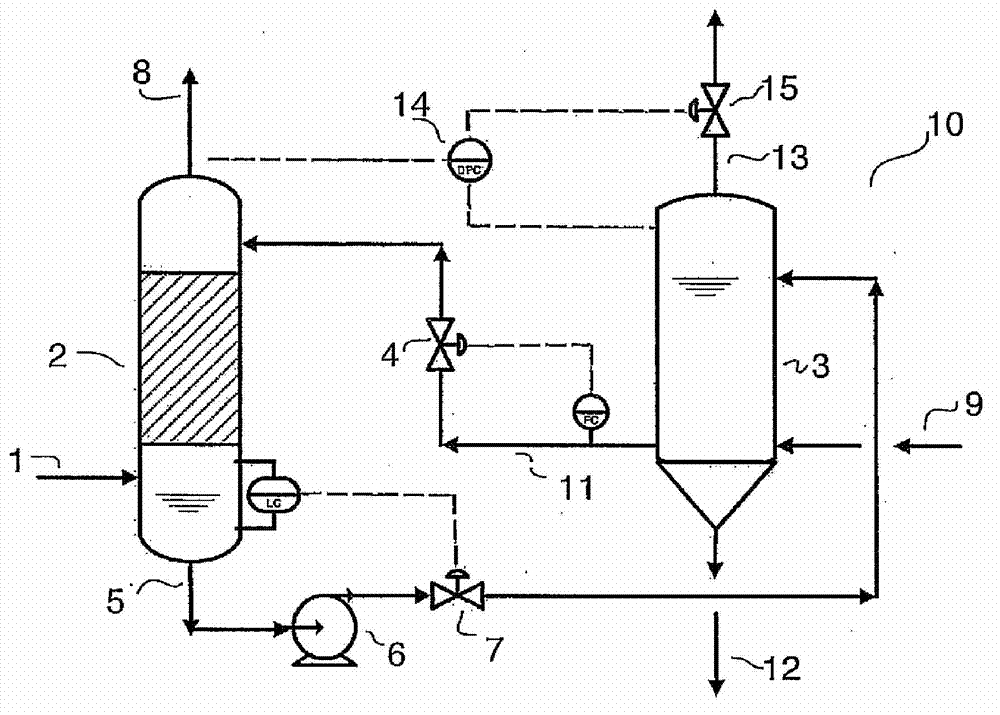

[0031] As mentioned above, the present invention relates to a novel high-pressure oxidizer that can be used to regenerate a liquid redox catalyst solution. This oxidizer can be used to provide a new process scheme for desulfurization of acid gas. The operating temperature of the oxidizer can range from about 25°C to about 55°C. The operating pressure is preferably higher than 100 psig and more preferably more than 5 psi higher than the operating pressure of the absorber in fluid communication with the oxidizer.

[0032] Now turn to the schematic illustration for handling the H 2 Diagram of this desulfurization process 10 of an S-contaminated gas stream. As shown, the exhaust gas stream (sour gas) is delivered via the feed line 1 to the absorber 2, where it is brought into contact with the chelated iron catalyst aqueous solution. Absorber 2 operates at a pressure higher than 100 psig. The catalyst solution is obtained from the high pressure oxidizer 3 via the fluid control valv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap