Tire contour measurement data correction method and tire visual inspection device

一种外观检查装置、测量数据的技术,应用在测量装置、采用光学装置、仪器等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below by referring to the drawings.

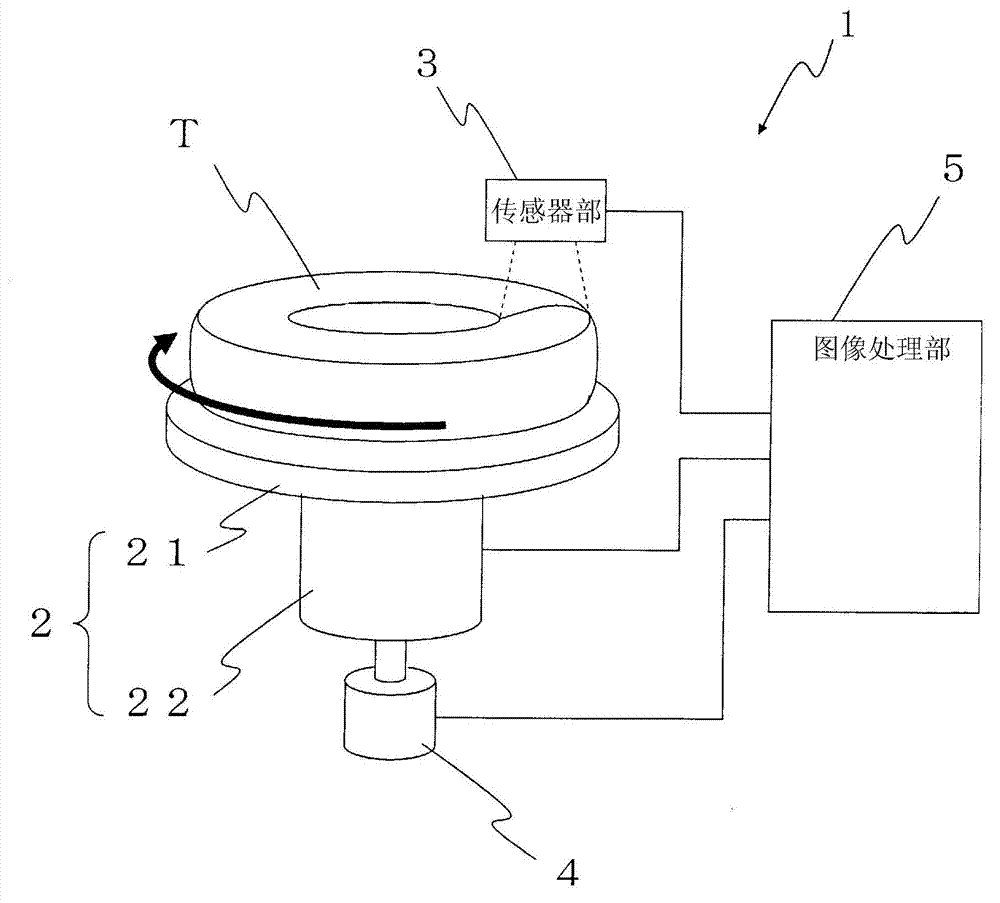

[0030] figure 1 is a block diagram showing the configuration of a tire appearance inspection device according to one embodiment of the present invention.

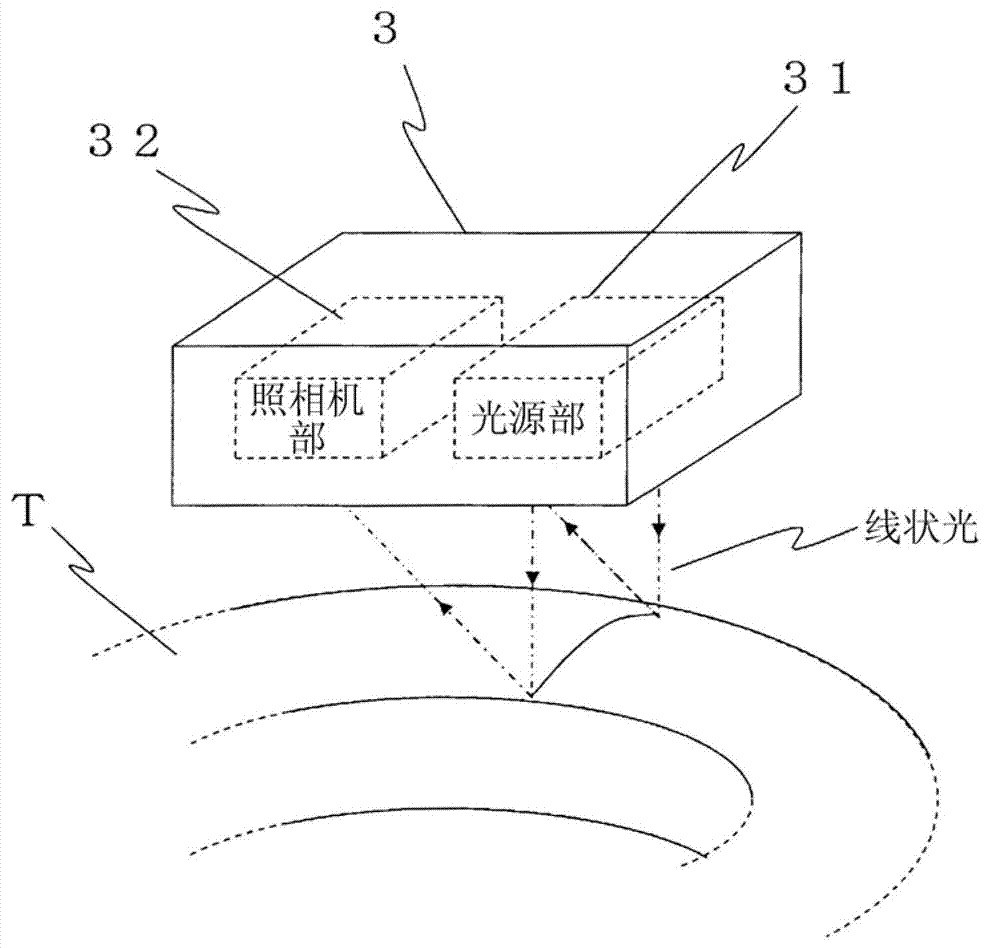

[0031] The tire appearance inspection device 1 has: a tire rotating unit 2 for rotating a tire T to be inspected by, for example, a stepping motor; a sensor unit 3 for irradiating the tire T with linear light and capturing an image of the linear light; The rotation angle detection unit 4 is used to detect the rotation angle of the tire rotation unit 2 ; and the image processing unit 5 is used to process the linear light image captured by the sensor unit 3 .

[0032] The tire rotating part 2 includes: a disc-shaped tire placing platform 21 for placing the tire T in a lateral direction; A stepping motor is built in to rotate and drive the tire placement table 21 .

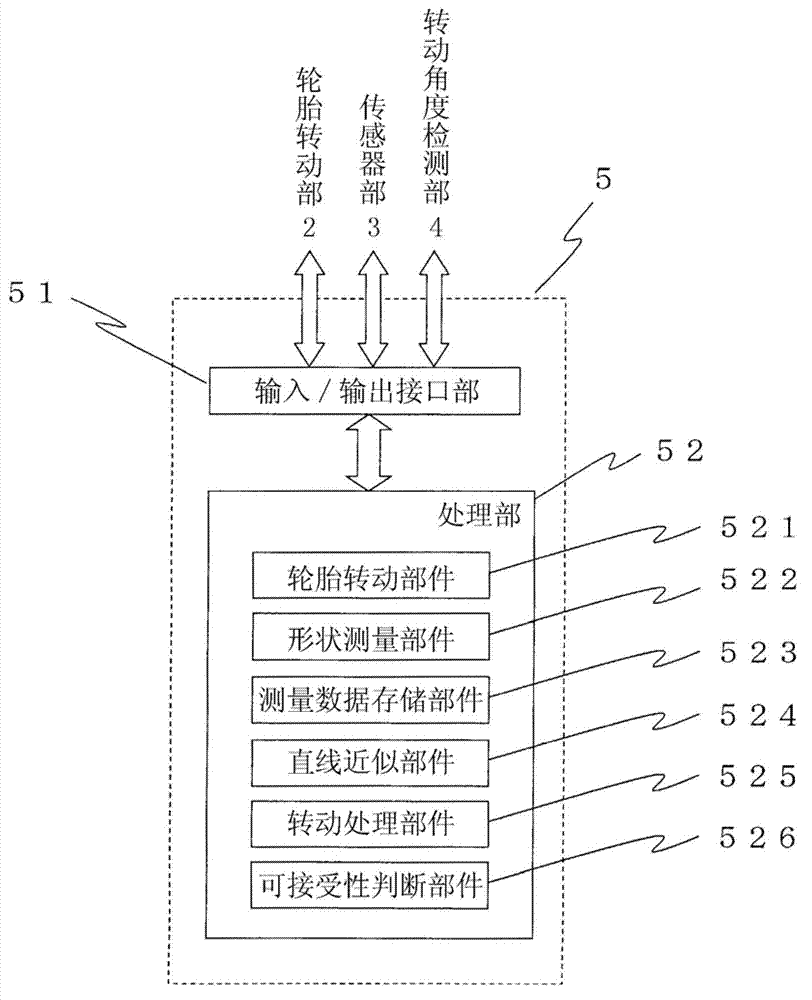

[0033] figure 2 It is a block diagram showing the config...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com