Rapid disassembly and assembly device of toilet bowl cover plate

A technology of toilet and cover, which is applied in the field of quick disassembly and assembly of toilet cover, can solve the problems of weak connection strength, poor connection strength, poor bearing torsion capacity, etc., and achieve quick disassembly, longitudinal connection strength and bearing capacity The effect of improving torsion ability and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

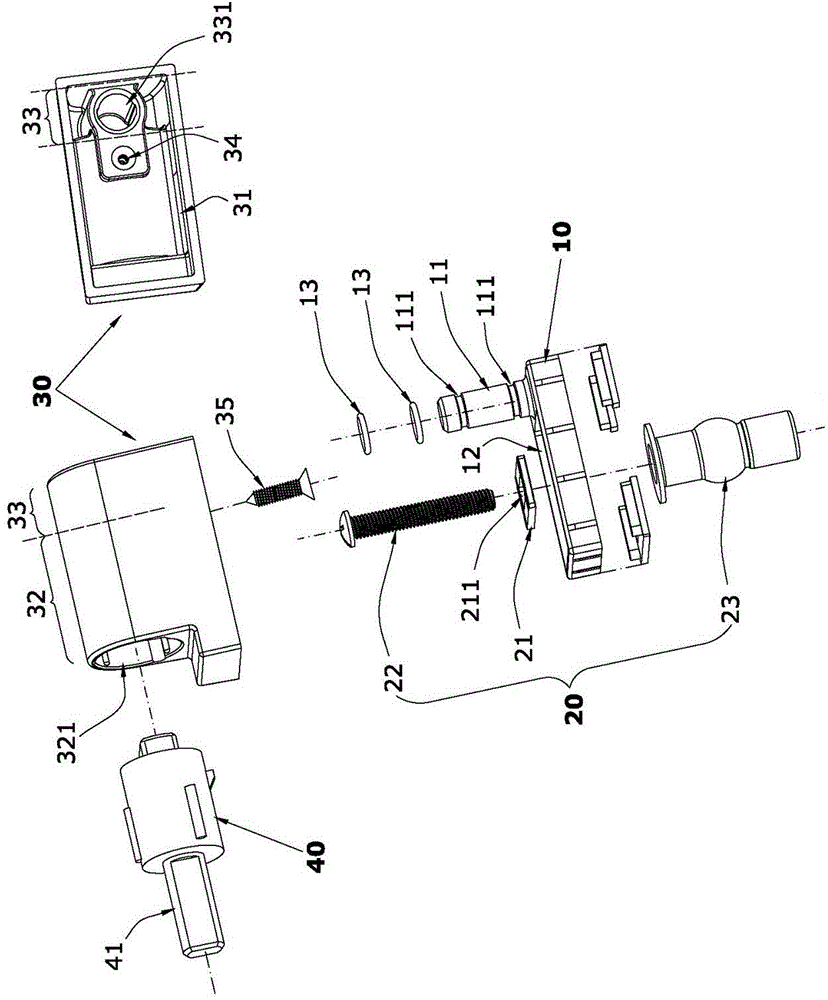

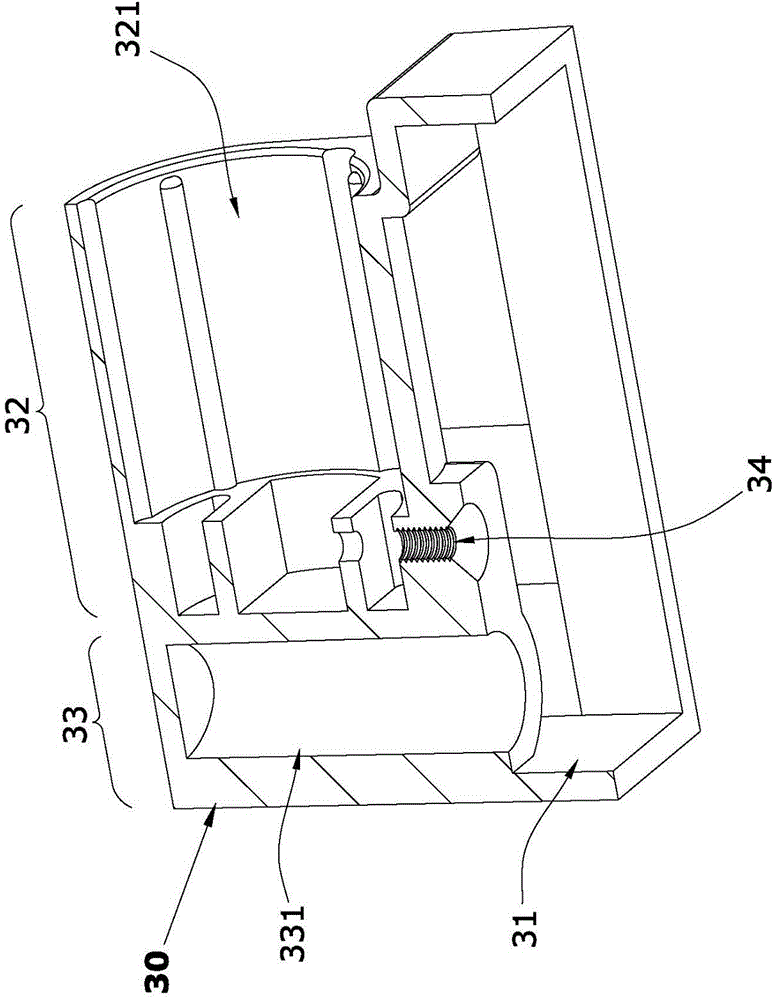

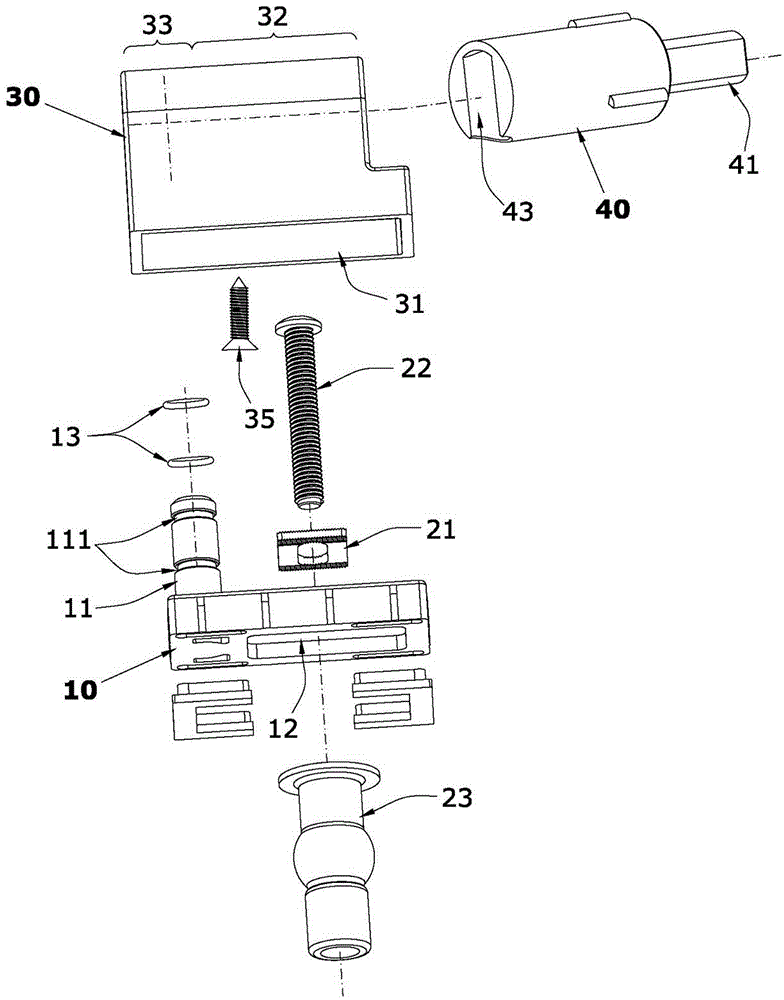

[0035] Embodiment two (The torsion-stop post of the base is plugged into the stop hole of the rotary damper inserted into the torsion-stop area).

[0036] like Figure 7 ~ Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the torsion-bearing area 32 and the torsion-stopping area 33 above the cavity 31 of the support 30 communicate with each other, and the rotation damper 40 of the torsion-bearing area 32 is inserted laterally into the torsion-stopping area. In the torsion area 33, the rotation damper 40 is inserted into the anti-torsion area 33. There is a stop hole 42, and the anti-torsion column 11 is plugged and connected with the stop hole 42. When the rotation damper 40 generates a torque to the cover plate, its reverse torque Directly acting on the rotary damper 40, the reverse torque does not act on the support 30, so that the fitting portion between the cavity 31 of the support 30 and the base 10 is not subjected to torsion. The...

Embodiment 4

[0039] Embodiment Four (The anti-torque column of the base is plugged into the anti-torsion pin hole of the support, and is locked through the torsion connection).

[0040] like Figure 12 As shown, the difference between this embodiment and Embodiment 1 is that a locking hole 36 communicating with the anti-torsion pin hole 331 is provided on the side wall of the support 30 anti-torsion area 33, and the anti-torsion post 11 of this embodiment is no longer provided. The ring groove 111, the anti-torsion column 11 and the anti-torsion pin hole 331 are plugged and matched. The present invention is provided with a locking hole 112 on the anti-torsion column 11 that is aligned with the locking hole 36, and a dial 70 is inserted into the locking hole 36. Engaged with the locking opening 112, the anti-torque column 11 on the base 10 is connected and fixed with the anti-torque pin hole 331 on the support 30, so as to realize the fast connection and fixation between the cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com