Outlet guiding device of seamless steel pipe rolling mill

An export-oriented, seamless steel pipe technology, applied in the direction of guiding/positioning/alignment devices, etc., can solve the problems of poor sealing, uncontrollable steel pipe jumping, etc., and achieve the effect of simple structure, flexible use, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

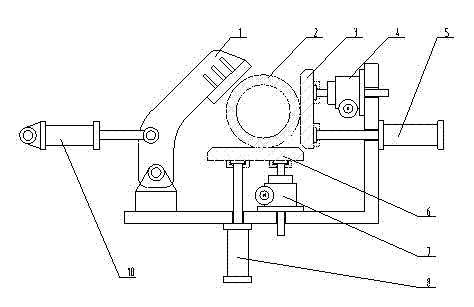

[0011] The present invention comprises a baffle 3 driven by a hydraulic cylinder 1 5 and an elevator 4, a baffle 2 6 driven by a hydraulic cylinder 2 8 and an elevator 7, and a buckle 1 driven by a hydraulic cylinder 3 9; the steel pipe 2 is placed In the enclosed space formed by baffle plate one 3, baffle plate two 6, and buckle tile 1 three.

[0012] The working process of the present invention is as follows: first adjust the baffle plate 1 3 and the baffle plate 2 6 to the required positions, and after the steel pipe 2 enters the platform formed between them, drive the buckle tile 1 to clamp the steel pipe 2 to control the steel pipe 2 beat.

[0013] The present invention can determine the clamping force of each clamping point on the steel pipe 2 by controlling the pressure of each hydraulic cylinder. The clamping force can be preset according to the actual situation so as not to damage the steel pipe 2 while guiding the steel pipe 2 .

[0014] The present invention prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com