Method for simultaneous roll-forming of threads and splines of shaft parts

A technology for roll forming and shaft parts, which is applied to threaded products, other household appliances, household appliances, etc., can solve problems such as troublesome adjustment of various types of workpieces, production quality, processing range and application limitations, etc. Achieve the effect of improving forming quality, consistent relative position and reducing forming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0020] The material of the workpiece 3 in this embodiment is 45 steel, and the formed part 4 has a spline part 41 and a thread part 42 at the same time.

[0021] A method for simultaneous roll forming of shaft parts with threaded splines, comprising the following steps:

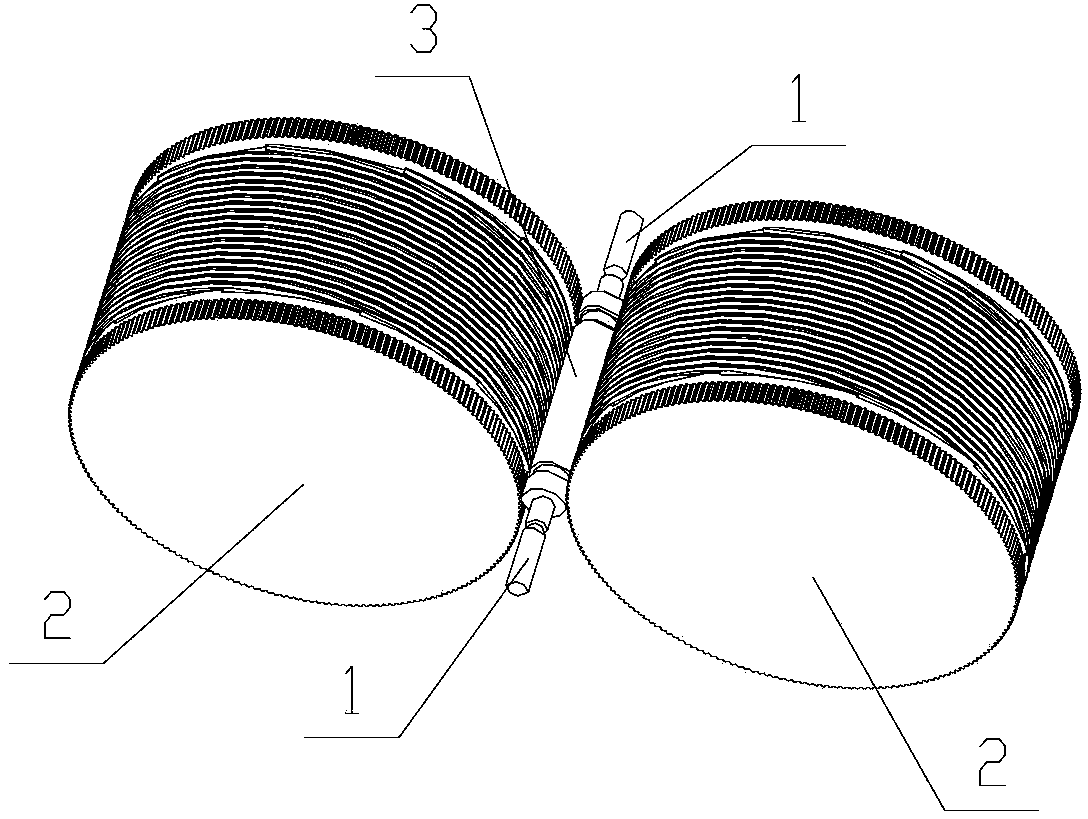

[0022] Step 1, refer to figure 1 , the workpiece 3 is clamped, and the workpiece 3 is clamped by the top 1, ensuring that the axis of the workpiece 3 is on the same level as the axes of the two rolling dies 2, and the axes of the two rolling dies 2 are parallel and symmetrically distributed on both sides of the workpiece 3;

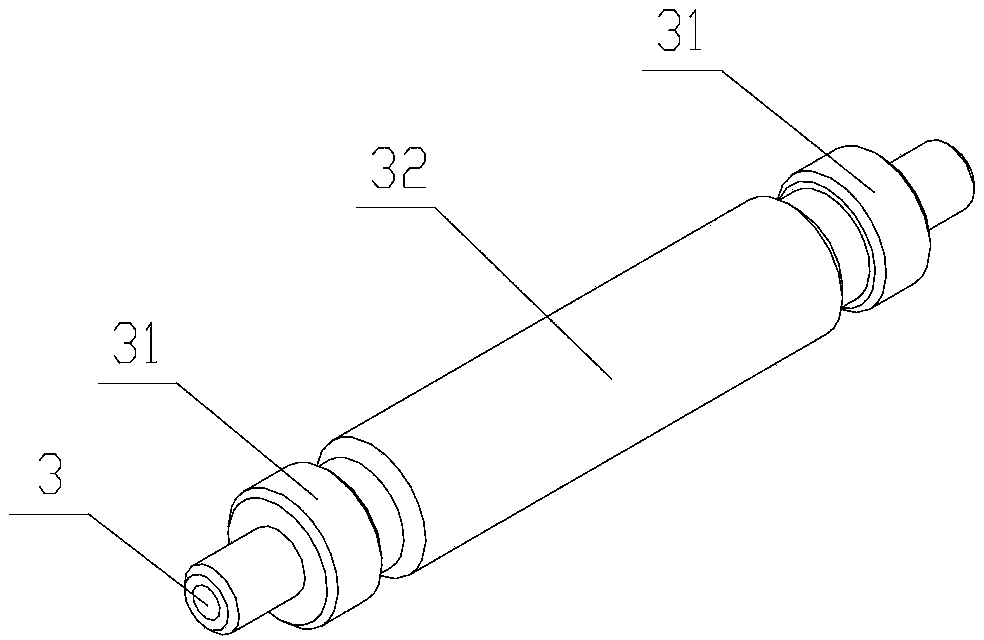

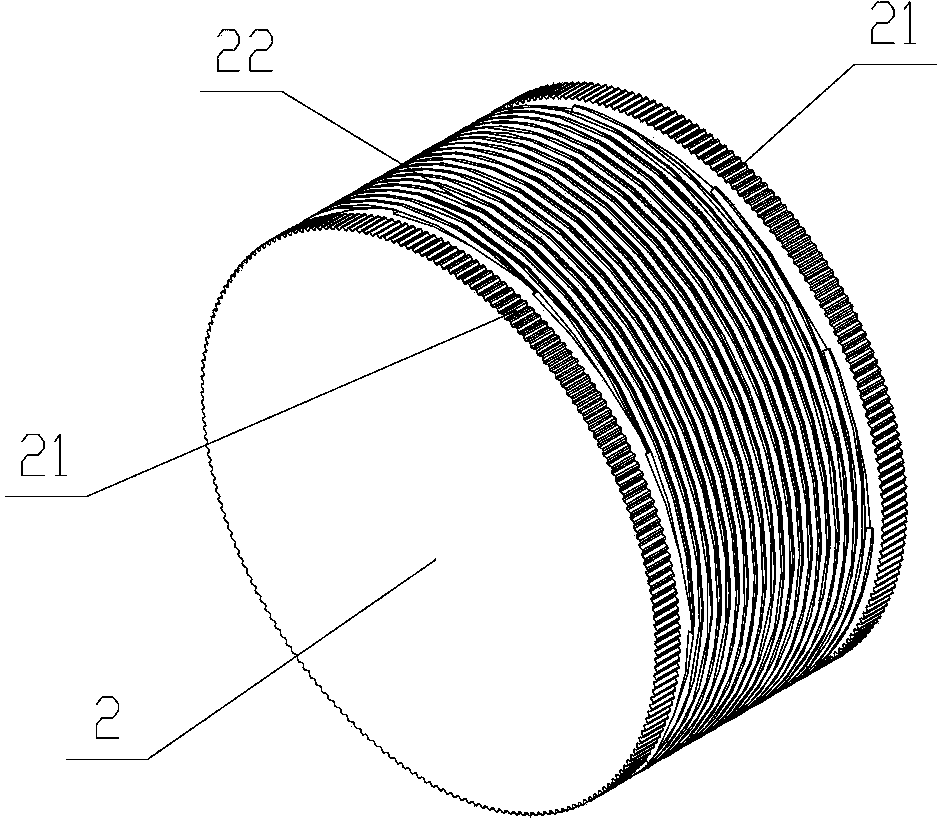

[0023] Step 2, the workpiece 3 is fed in the direction of the rolling die 2; refer to figure 2 , there is a first roll forming part 31 and a second roll forming part 32 on the workpiece 3, referring to image 3 , there is spline shape part 21 and thread shap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap