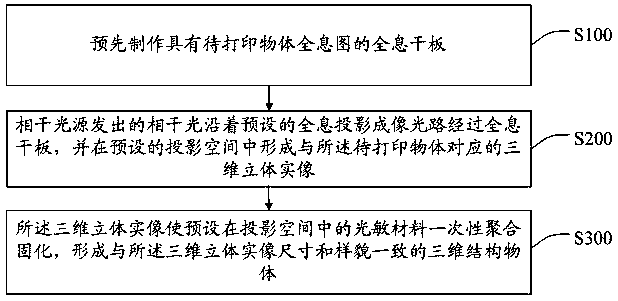

3D (three-dimensional) printing method and printing system based on holographic projection

A holographic projection and 3D printing technology, applied in the field of 3D printing methods and systems based on holographic projection, can solve the problems of inability to produce complex structures, poor forming effect and precision, and achieve the goal of shortening forming time, improving work efficiency and forming accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

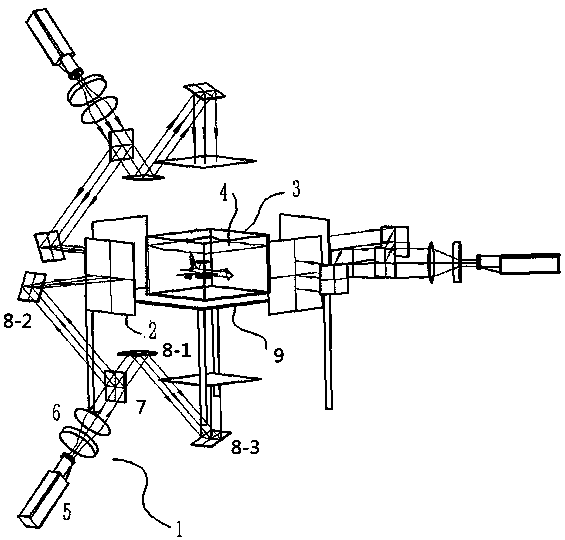

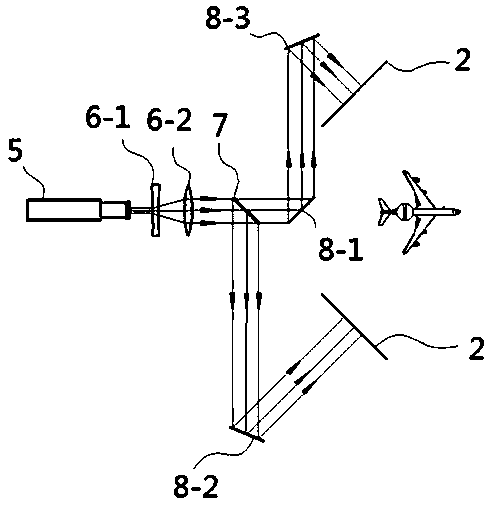

[0035] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0036] 3D printing technology was born in the late 1980s. It is a high-tech manufacturing technology based on the material accumulation method. It is considered to be a major achievement in the manufacturing field in the past 20 years. It integrates mechanical engineering, CAD, reverse engineering technology, layered manufacturing technology, numerical control technology, material science, and laser technology, and can automatically, directly, quickly and accurately transform design ideas into prototypes with certain functions or directly manufacture parts , so as to provide a high-effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com