Angular adjustment accessory

An angle adjustment and parts technology, applied in the field of angle adjustment parts, can solve the problems of inability to perform fine adjustment, inability to claws, small gears, and few angle switching stages, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

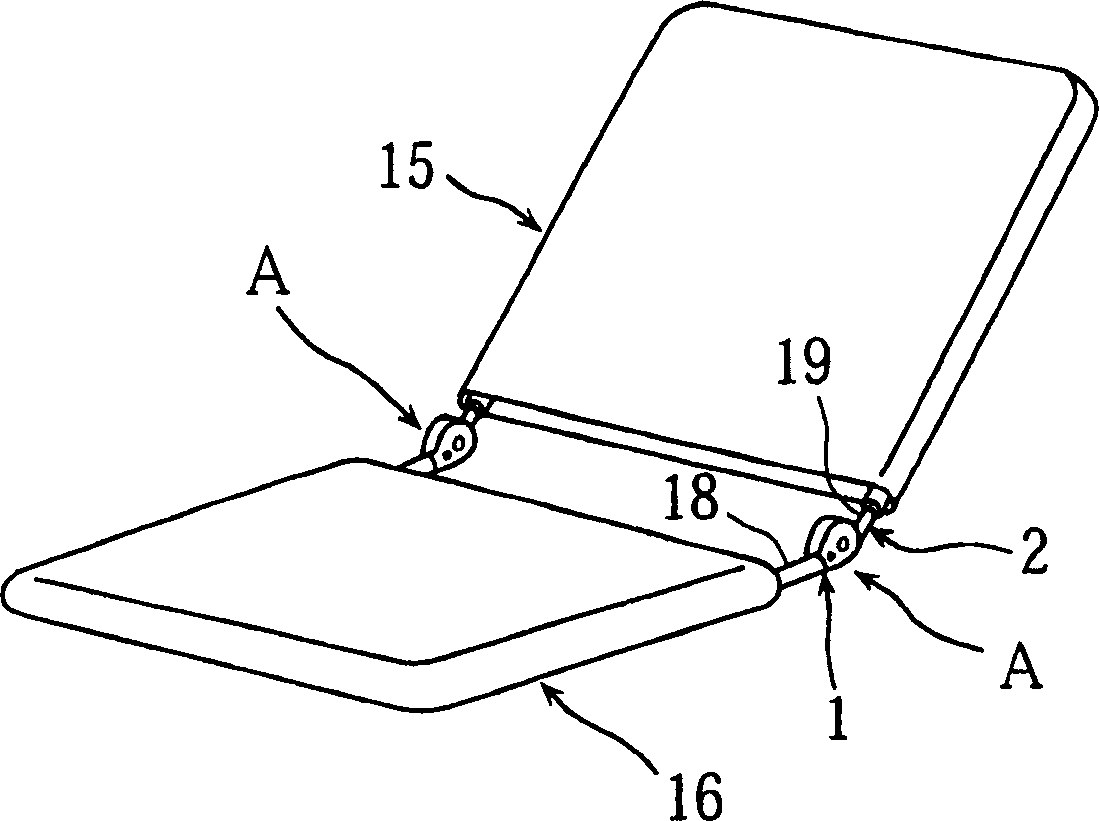

[0038] Angle adjustment parts of the present invention, such as figure 1 As shown in the perspective view, it is a part that is arranged between the backrest 15 and the seat portion 16 so that the inclination angle of the backrest 15 can be adjusted on the seat with the backrest 15 and the seat portion 16 . That is, the angle adjustment part A is a joint part (connection part) having an angle adjustment function. In addition, this part A can be used not only on the seat, but also on sofas, headrests, footrests, etc. Shelves etc. with doors swinging open and close.

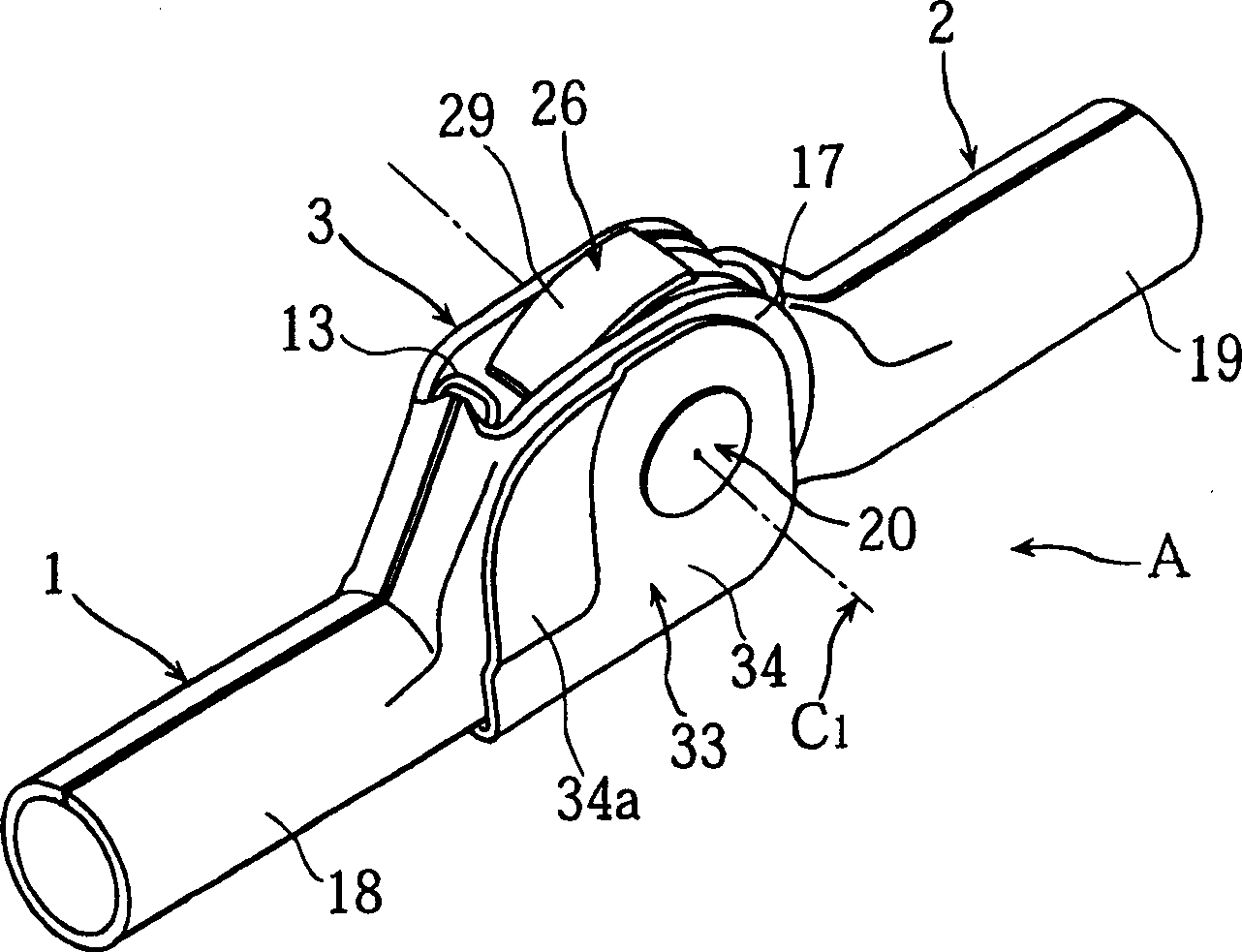

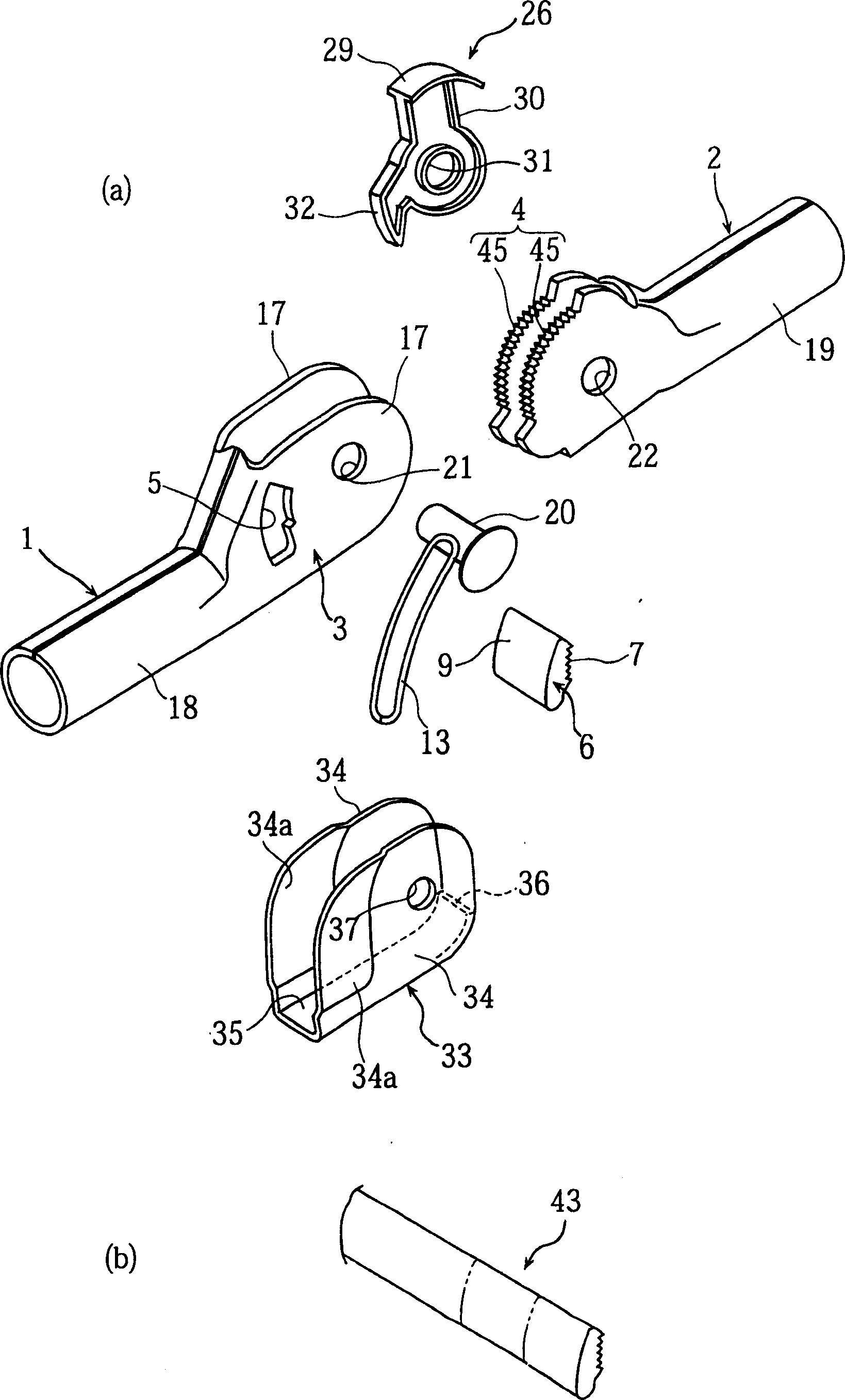

[0039] figure 2 is a perspective view of the angle adjustment part A, image 3 is its exploded perspective view.

[0040] The angle adjustment part A of the present invention has: a first arm 1 with a shell portion 3; 1 The swinging way is pivotally connected with the first arm 1, and has a first axis C 1 Centered gear part 4. That is, the first arm 1 and the second arm 2 are pivotally mounted so that the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com