Film heat-sealing machine

A film heat sealing and transverse heating technology, applied in the field of heat sealing machines, can solve the problems of plastic film deformation, time-consuming, and manual cutting cannot ensure accuracy, and achieve the effect of ensuring quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

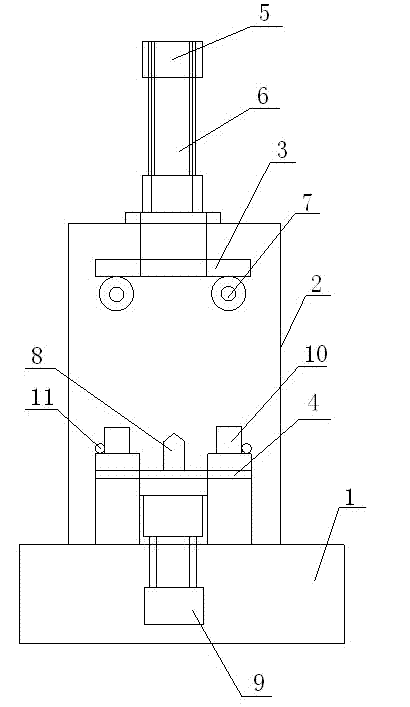

[0011] Such as figure 1 As shown, a kind of film heat sealing machine of the present invention comprises machine base 1 and frame 2, and frame 2 is arranged on machine base 1, and heat sealing device is installed on frame 2, and heat sealing device comprises upper horizontal heat sealing frame 3, lower The horizontal heat sealing frame 4 and the cylinder 5, the lower end of the cylinder 5 is connected with the upper end of the piston rod 6, the lower end of the piston rod 6 is connected with the upper horizontal heat sealing frame 3, the lower ends of the upper horizontal heat sealing frame 3 are glued with elastic rubber strips 7, and the upper horizontal heat sealing frame 3 The lower frame 2 is provided with a lower horizontal heat-sealing frame 4, and a cutter 8 is arranged in the middle of the lower horizontal heat-sealing frame 4. The tw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap