End-of-roll paper detection device, printing apparatus and detection method for end-of-roll paper

A technology of detection device and printing equipment, applied in printing device, printing and other directions, can solve the problems of trouble, inaccurate detection results, increase of users, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The roll paper end detection device, the printing equipment and the roll paper end detection method will be further described in detail below with reference to the embodiments and the accompanying drawings.

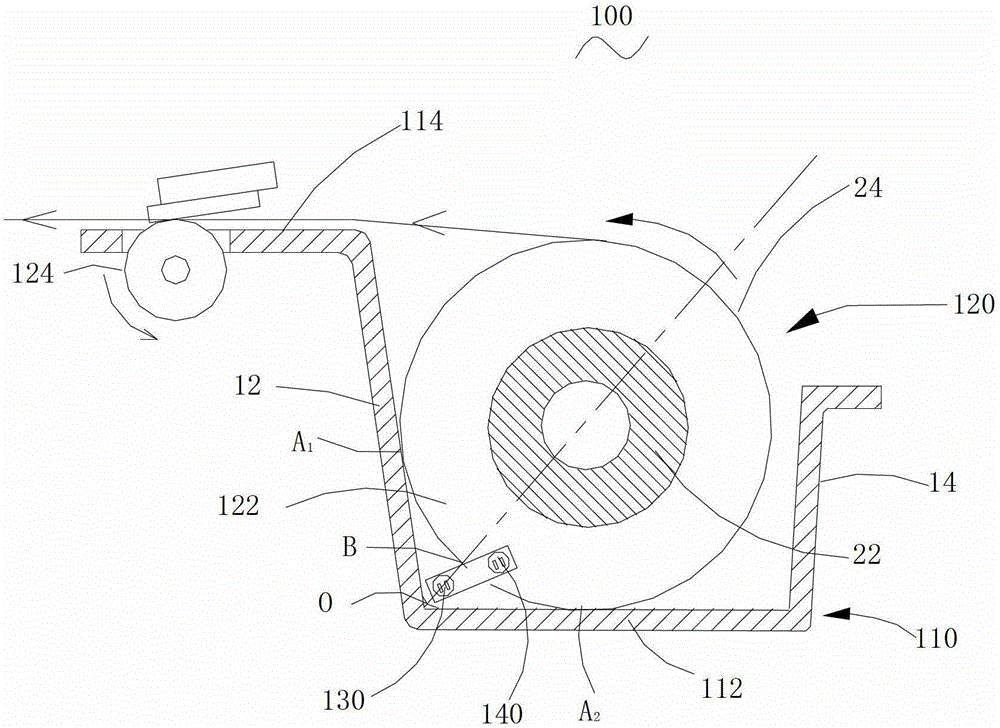

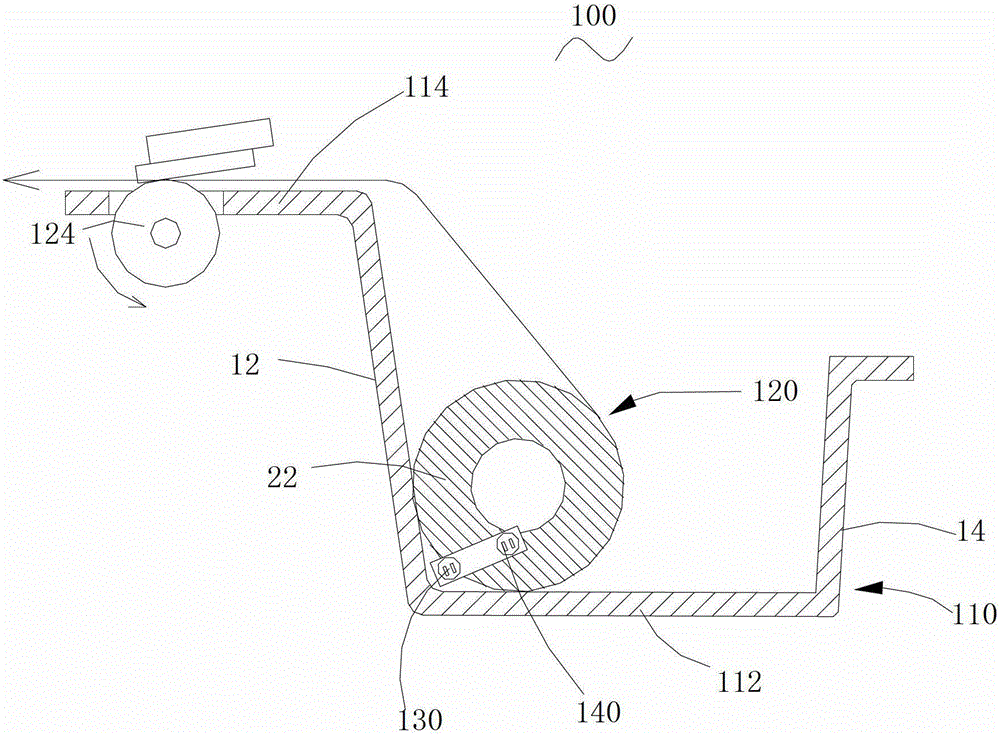

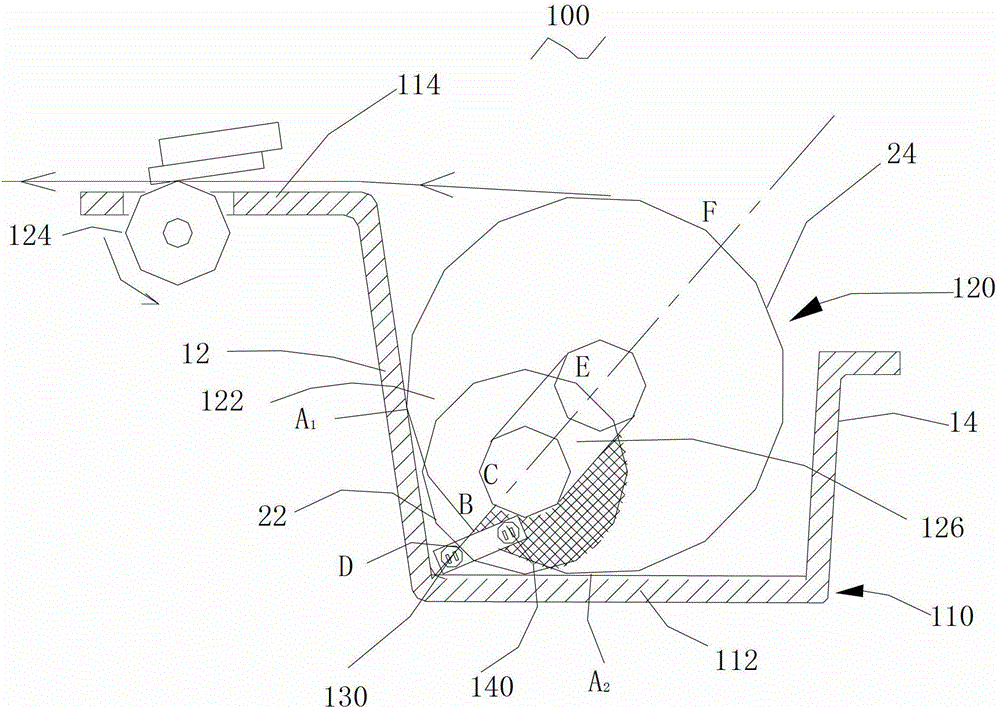

[0040] see figure 1 , the roll paper end detection device 100 of an embodiment includes a paper bin 110 , a roll paper assembly 120 , a first photoelectric sensor 130 and a second photoelectric sensor 140 .

[0041] The shape of the paper bin 110 is a square box, which includes a substantially square bottom wall 112 and four side walls connected to the four edges of the bottom wall 112, which are respectively a left side wall 12, a right side wall 14, and a front side wall. (not shown) and rear side wall (not shown). The bottom wall 112 and the four side walls form an open warehouse for storing roll paper. The bottom wall 112 and the four side walls can be integrally formed to simplify the assembly process. In other embodiments, the right side wall, front side w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com