Oil-resistant and cold-resistant steel wire rope core conveyer belt

A technology of steel wire rope core and conveyor belt, which is applied in the direction of conveyor, transportation and packaging, adhesive type, etc. Brittleness and other problems, to ensure that the adhesive strength is not reduced, the adhesive strength is not reduced, and the effect of preventing transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

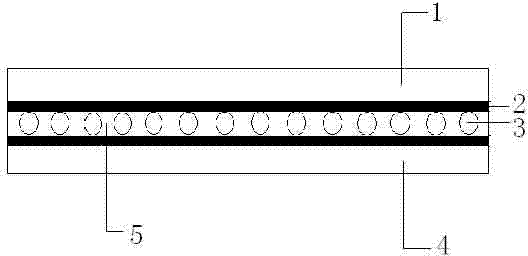

[0021] As shown in the drawings of the description, an oil-resistant and cold-resistant steel cord conveyor belt according to the present invention includes an upper covering rubber layer 1, a crack-resistant intermediate rubber 2, a high-adhesive core rubber 5, a steel wire rope 3 and a lower covering rubber layer 4 . Made by following steps:

[0022] 1 Mixing: The main rubber is mixed with carbon black as the main reinforcing agent, anti-aging agent, vulcanizing agent, plasticizer and other additives are mixed in a high-performance internal mixer according to the two-stage method, and the rubber is mixed in the first stage. Accelerators are added to make oil-resistant and cold-resistant rubber. The whole condition is completed under automatic conditions to ensure the uniformity and stability of rubber mixing.

[0023] 2. Calendering: The rubber compound obtained by mixing is extruded and calendered, and bonded with the skeleton material. The process strictly controls pr...

Embodiment 2

[0026] Covering rubber formula: 100 parts of nitrile rubber, 5 parts of zinc oxide, 1 part of stearic acid, 1.8 parts of S, 2 parts of anti-aging agent 4010NA, 2 parts of anti-aging agent BLE, 5 parts of tackifying resin, 8 parts of DOA, liquid nitrile rubber 8 parts, 30 parts of N220, 30 parts of N330, 1 part of accelerator CZ, 0.5 parts of accelerator DM.

[0027] Intermediate rubber 2 formula: 60 parts of nitrile rubber, 40 parts of natural rubber, 4 parts of zinc oxide, 1 part of stearic acid, 2.0 parts of S, 1 part of anti-aging agent 4010NA, 1 part of anti-aging agent BLE, 8 parts of tackifying resin, DOA 7 parts, 6 parts of liquid nitrile rubber, 1.5 parts of adhesive PL600, 1 part of RF, 1.5 parts of HMMM, 1 part of CZ, 0.5 parts of accelerator DM.

[0028] High adhesive core rubber 5 formula: 60 parts of natural rubber, 40 parts of styrene-butadiene rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 2.0 parts of S, 1.5 parts of microcrystalline paraffin, 1 part o...

Embodiment 3

[0030] Covering rubber formula: 100 parts of nitrile rubber, 4.5 parts of zinc oxide, 1.2 parts of stearic acid, 1.8 parts of S, 1.5 parts of anti-aging agent 4010NA, 2.5 parts of anti-aging agent BLE, 5 parts of tackifying resin, 8 parts of DOS, liquid nitrile 8 parts of rubber, 30 parts of N220, 30 parts of N330, 1 part of accelerator NOBS, 0.5 parts of accelerator DM.

[0031] Intermediate rubber 2 formula: 65 parts of nitrile rubber, 35 parts of natural rubber, 4 parts of zinc oxide, 1 part of stearic acid, 2.0 parts of S, 1 part of anti-aging agent 4010NA, 1 part of anti-aging agent BLE, 8 parts of tackifying resin, DOS 7 parts, 6 parts of liquid nitrile rubber, 2 parts of RF, 3 parts of HMMM, 1 part of CZ, 0.5 parts of accelerator DM.

[0032] High adhesion core rubber 5 formula: 70 parts of natural rubber, 30 parts of butadiene rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 2.0 parts of S, 1.5 parts of microcrystalline paraffin, 1.5 parts of anti-aging agent 40...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap