Backing plate for sleeper

A sleeper and backing plate technology, which is applied in the field of railway accessories, can solve the problems of poor sleeper protection effect, large temperature influence, uneven stress distribution, etc., to overcome poor vibration damping effect, reduce wear and consumption, and have good energy saving and environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

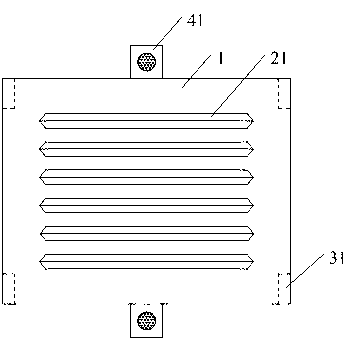

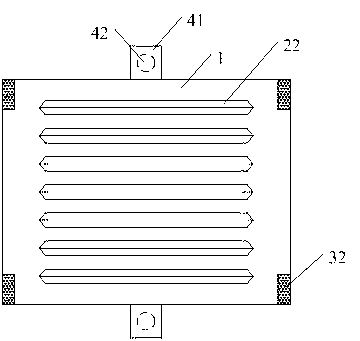

[0022] According to an embodiment of the present invention, a backing plate for sleepers is provided. Such as figure 1 with figure 2 As shown, a backing plate for a sleeper of this embodiment includes a plate-shaped body (such as the plate-shaped body 1) for matching the cushion to be installed on the lower surface of the sleeper, and the upper surface of the plate-shaped body is provided with evenly spaced plates. V-shaped grooves (such as V-shaped groove 21), and a plurality of inverted V-shaped grooves (such as inverted V-shaped groove 22) that are evenly spaced and arranged in a staggered arrangement on the lower surface of the plate-shaped body; On the lower surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com