Environment-friendly treatment method for medical care waste

An environmental protection treatment and medical waste technology, applied in the direction of combustion method, gas treatment, separation method, etc., can solve the problems of incomplete disposal of medical waste, high cost of ozone production, incomplete sterilization, etc., to avoid health threats, High electrothermal conversion efficiency and the effect of reducing the generation of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Such as Figure 9 Shown, a kind of medical care waste environmental treatment method comprises the following steps:

[0060] S1, the packaged medical waste is first sent into the crushing mechanism from the feed port through the medical waste transport vehicle, avoiding manual handling and contact with medical waste; the second motor drives the turntable to rotate;

[0061] S2, the medical waste enters the cylinder, and the second motor is started for crushing;

[0062] S3, after S2, after the combustion in the first combustion chamber and the reaction in the reaction chamber, air is introduced into the second combustion chamber, and the combustible gas generated by pyrolysis enters the second combustion chamber for full combustion;

[0063] S4, the flue gas after passing through the heat exchanger enters the dust removal mechanism through the dust removal pipe, the flue gas contains a large amount of smoke dust, and the dust is filtered through the dust removal filter...

Embodiment 2

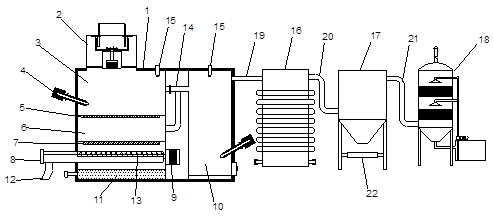

[0067] Such as figure 1 , 7 , 8, a medical care waste environmental protection treatment system; including a housing 1; the top of the housing 1 is provided with a crushing mechanism 2, the bottom of the crushing mechanism 2 is a first combustion chamber 3, the first combustion chamber 3 is located in Inside the housing 1, a reaction chamber 6 is provided below the first combustion chamber 3, and a slagging cylinder 8 is provided below the reaction chamber 6; The first leaking plate 5, the second leaking plate 7 is provided between the reaction chamber 6 and the slag discharge tube 8; the side walls of the first combustion chamber 3 and the reaction chamber 6 are connected with turning smoke pipes 14, turning smoke A one-way valve is provided on the pipe 14, and the other end of the turning smoke pipe 14 is connected to the second combustion chamber 10, and the second combustion chamber 10 is arranged inside the housing 1; the first combustion chamber 3 and the second combust...

Embodiment 3

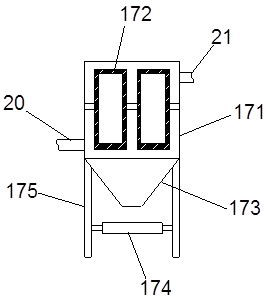

[0076] On the basis of Example 1, as figure 2 As shown, the dust removal mechanism 17 includes a dust removal tower body 171, the dust removal pipeline 20 is connected to a position near the bottom of the dust removal tower body 171, and the adsorption pipeline 21 is connected to a position near the top of the dust removal tower body 171; the dust removal tower The body 171 has a cylindrical structure, and a funnel 173 is sealed and connected under the dust removal tower body 171, and the funnel 173 is an inverted truss-shaped structure; the inside of the dust removal tower body 171 is provided with a plurality of dust removal filter elements 172, and the dust removal filter elements 172 are cylindrical The bottom of the dust removal tower body 171 is connected with a plurality of legs 175 for support; the bottom of the funnel 173 is provided with a dust collection box 174, and the dust collection box 174 is connected to the legs 175 through a connecting piece provided.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com