Ultrasonic-wave dynamic sealing device and method

A sealing device and ultrasonic technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., to reduce maintenance costs, facilitate structural assembly, and reduce wear and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

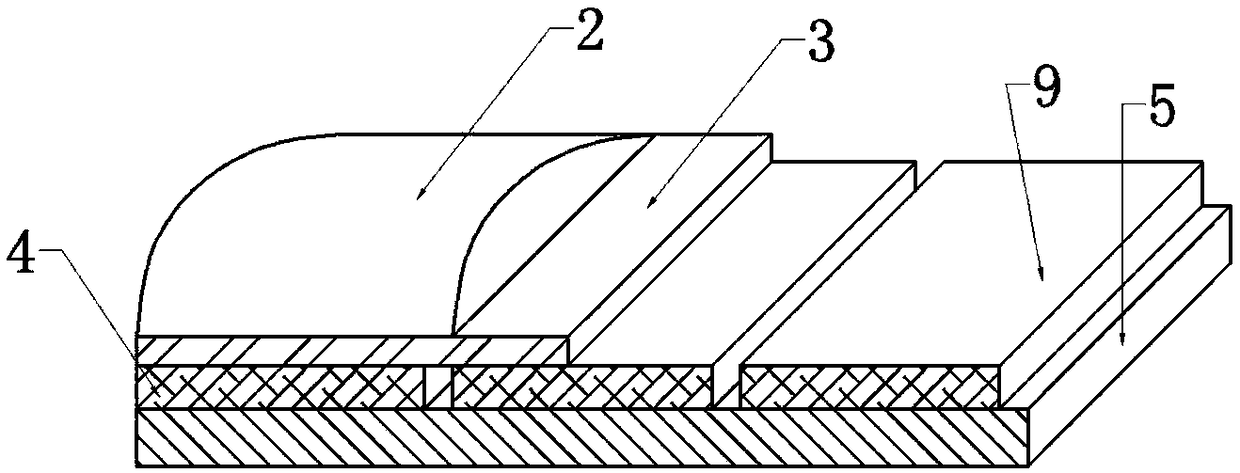

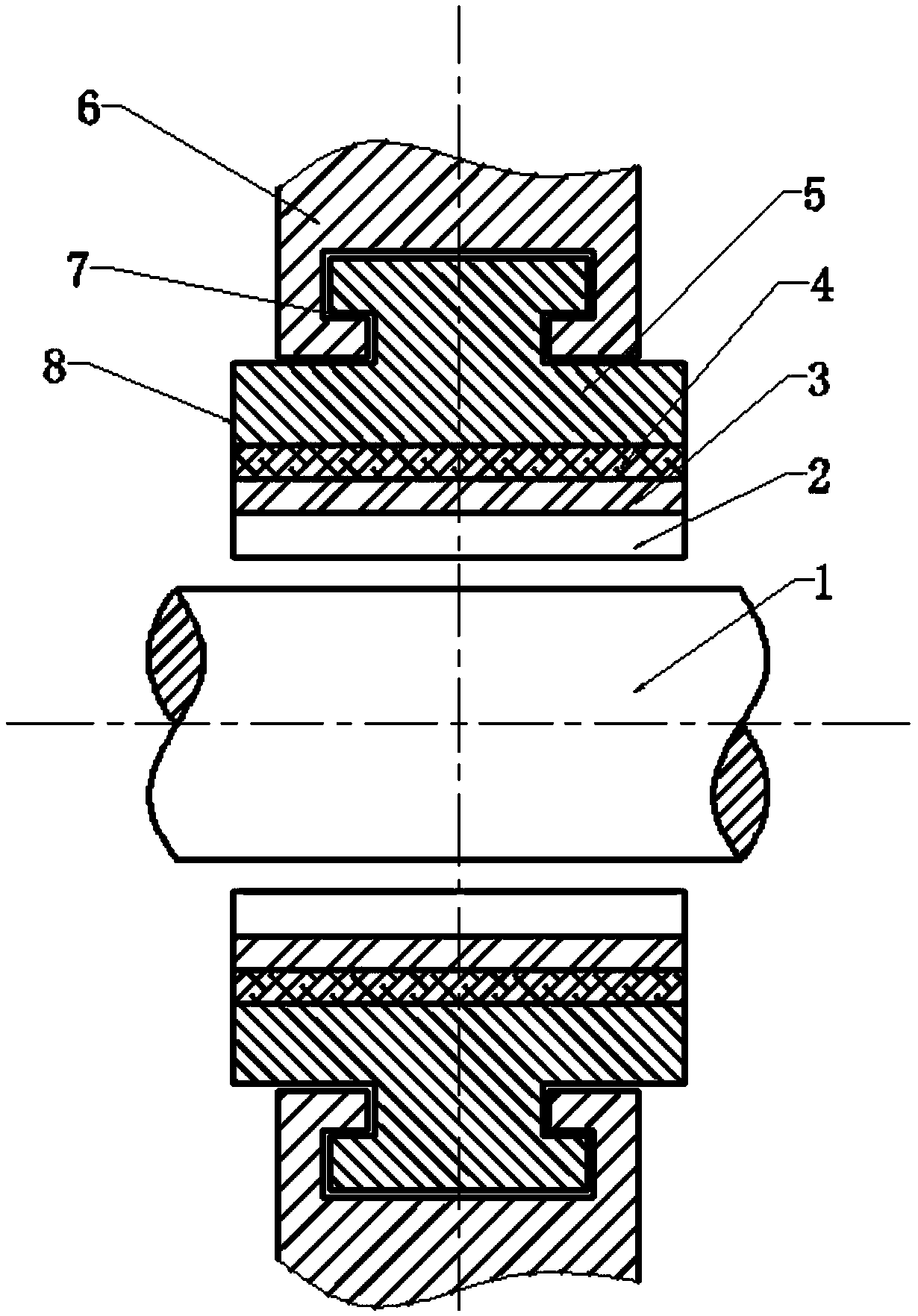

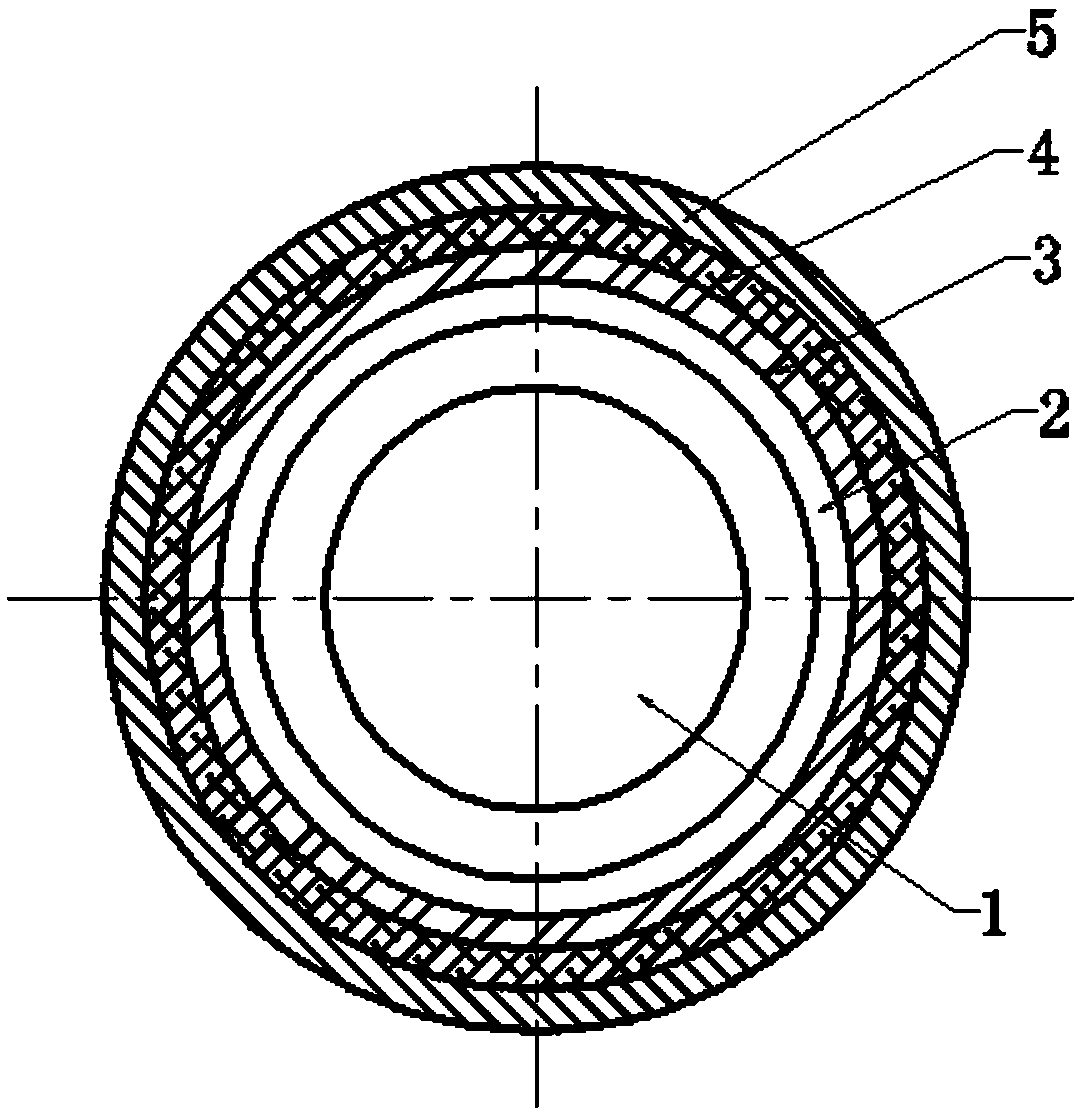

[0029] The present invention is a dynamic sealing device for rotating machines. The backing 5 is hot-pressed after being fully mixed with tungsten powder and epoxy resin. The particle size of the tungsten powder is 5 μm, and the volume fraction is 15%. The outer side of the backing 5 is connected in contact with In the T-shaped groove of the sealing groove, it is connected on the sealing sleeve 6 through the T-shaped groove; the acoustic-electric chip 9 is a rectangular PZT piezoelectric ceramic sheet, the ultrasonic frequency of the acoustic-electric chip 9 is selected at about 60 kHz, and the thickness of the acoustic-electric chip 9 is about 60 kHz. 1 / 2 wavelength when propagating in the acoustic electric chip 9;

[0030] The matching layer 3 is made of low-viscosity epoxy resin filled with alumina in a single layer, the particle size of alumina powder is 2.5 μm, and the volume fraction is 25%. The filler and the base material are cast into a thin layer by casting. 1 / 4 wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com