Pneumatically actuated liquid dispensing valve and method

A technology for dispensing valves, liquids, used in the direction of liquid injection devices, devices for applying liquid to surfaces, valve details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

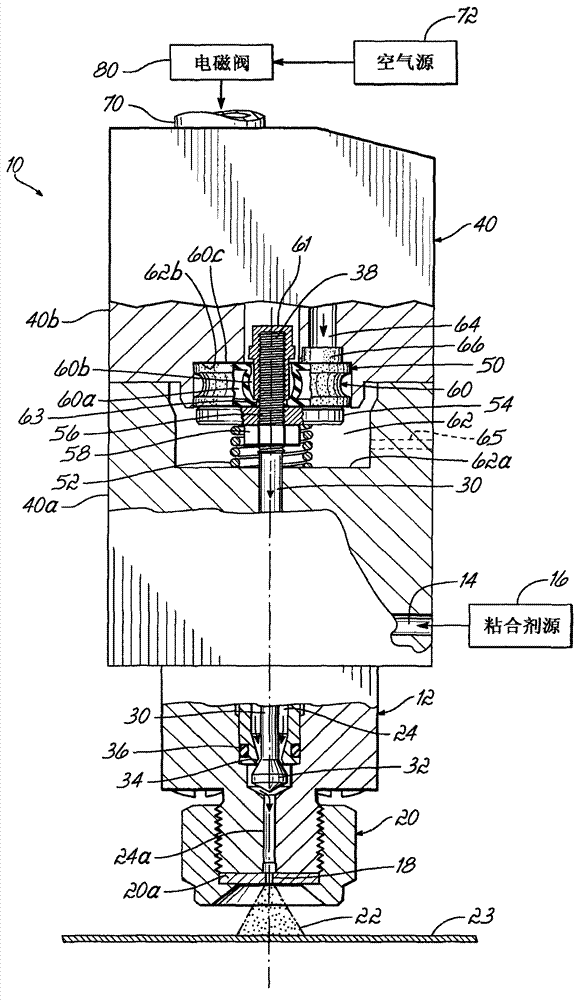

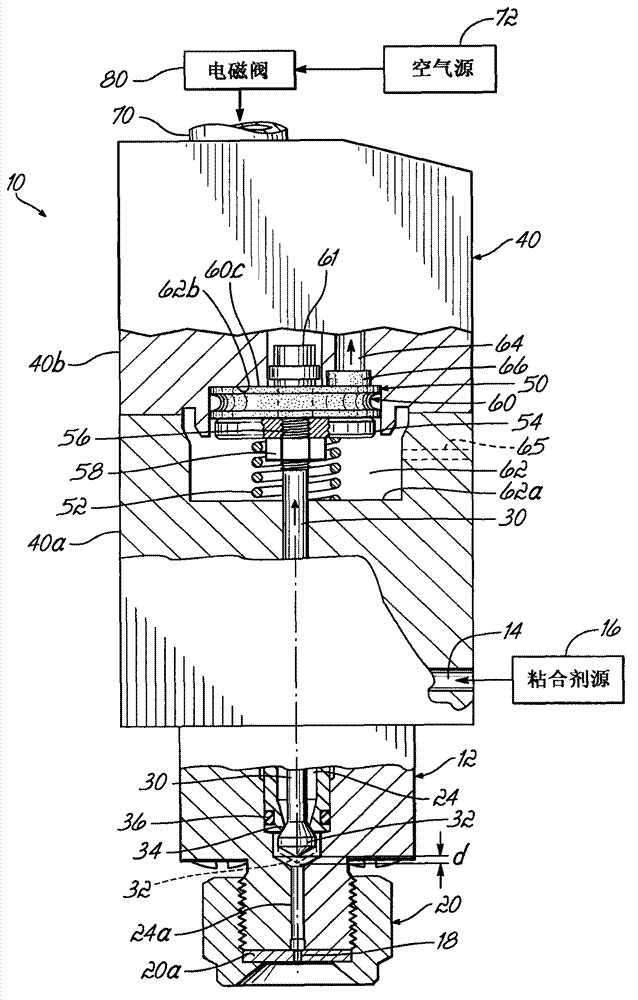

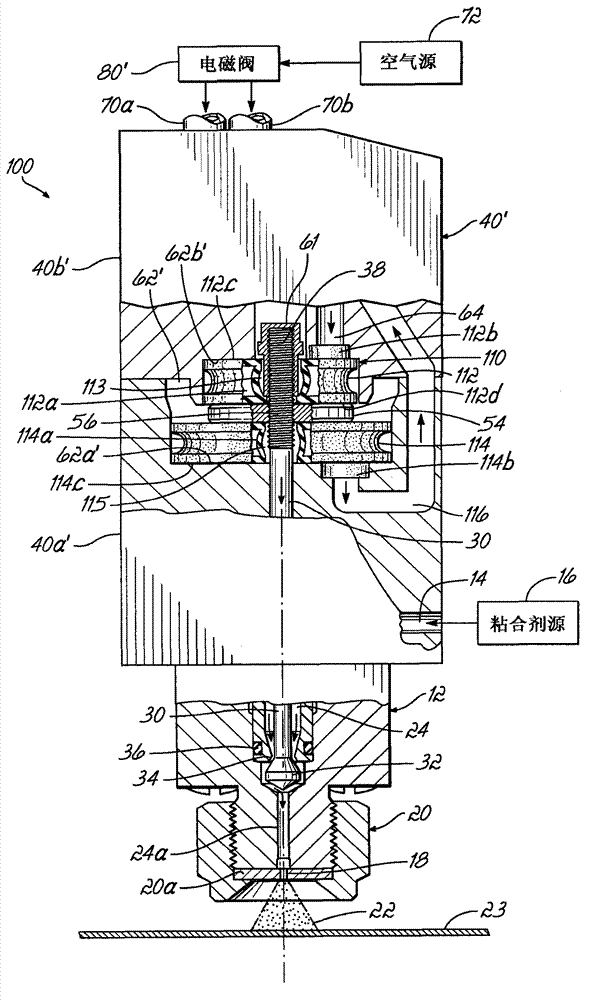

[0017] figure 1 and figure 2 A first embodiment of a liquid dispensing valve 10 is shown. Valve 10 includes a liquid dispensing portion 12 having a liquid inlet 14 for receiving liquid, such as a hot melt adhesive, from a pressurized source 16 . The liquid dispensing portion 12 also includes a liquid outlet 18 associated with the insert 20a of the nozzle 20 to discharge the liquid 22 onto the substrate 23 . It will be appreciated that the nozzle 20 is shown schematically and may have a variety of different forms and discharge liquid in a variety of ways. When dispensing liquid hot melt adhesive, for example, a swirl pattern, bead pattern, dot or other spray pattern may be expelled. A liquid passage 24 communicates between the liquid inlet 14 and the liquid outlet 18 . The valve member 30 is mounted to move relative to the liquid outlet 18 between an open position and a closed position, respectively at figure 1 and figure 2 shown in . More specifically, the valve membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com