A Batch Detection Method for Spatial Dimensions of Small Pin Shaft Parts

A technology of space size and batch detection, which is applied in the field of part size measurement, can solve problems such as low measurement efficiency, decreased measurement accuracy, and long production cycle of parts, so as to reduce artificial measurement errors, improve measurement accuracy, and improve measurement efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments, but the scope of protection is not limited to the description.

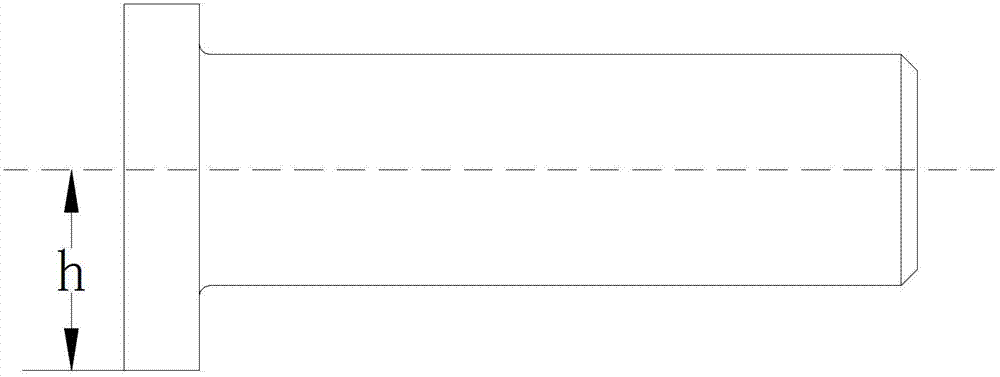

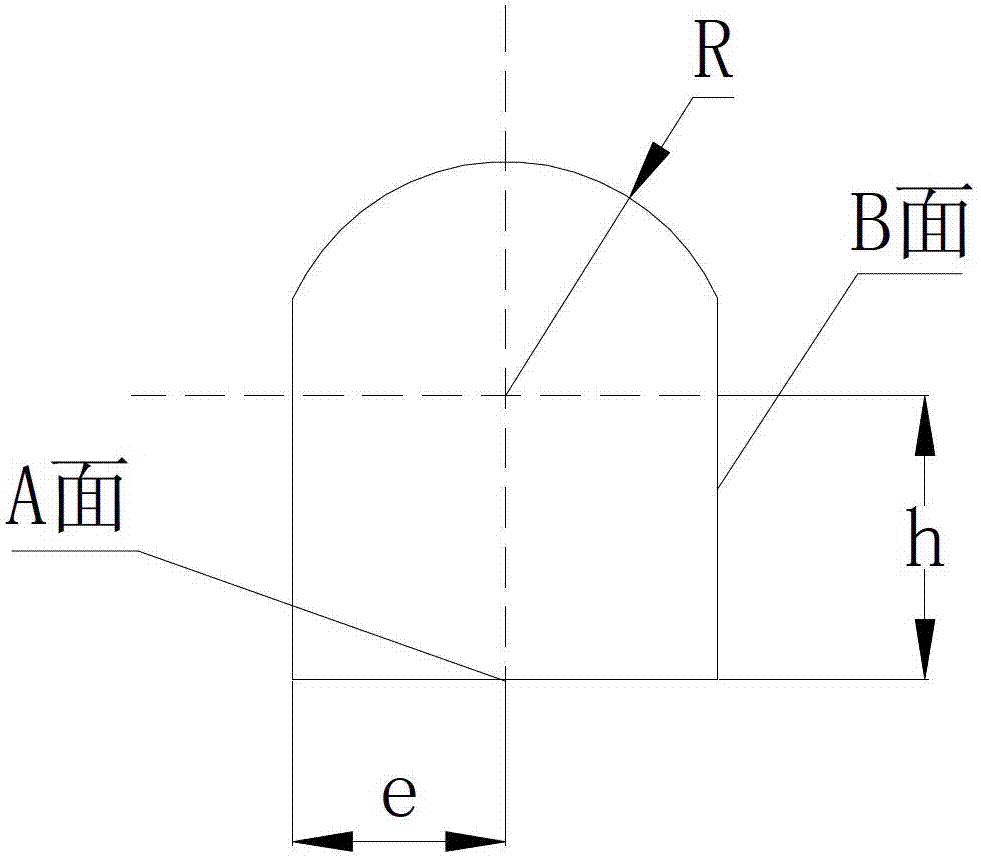

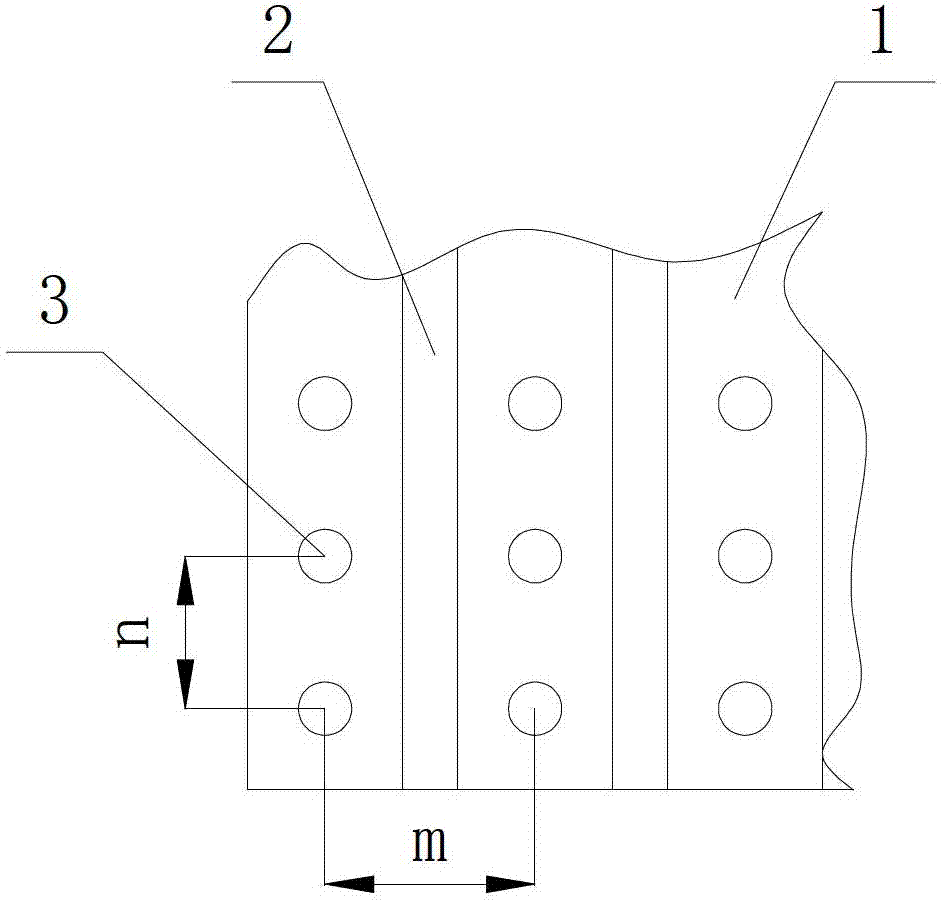

[0019] Such as figure 1 , figure 2 , processing this type of parts, the spatial dimensions e and h of the parts, the existing measurement methods cannot directly measure the spatial dimensions, and often use the method of indirect measurement of a single piece to calculate the measurement results.

[0020] Such as figure 1 , a batch detection method for the spatial dimensions of small pin-shaft parts, which includes the following steps:

[0021] (1) Analyze the space size to be measured, the e size and h size are related to the arc R, and determine to use the automatic measurement function of the optical imager to realize batch simultaneous detection;

[0022] (2) Determine the detection method of a single part, establish a part measurement coordinate system, use the A surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com