A mode-controlled cascaded liquid crystal microlens array

A liquid crystal microlens and mode control technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of gradient-type refractive index curves not being smooth enough, increase response speed, etc., and achieve the effect of smooth contour and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

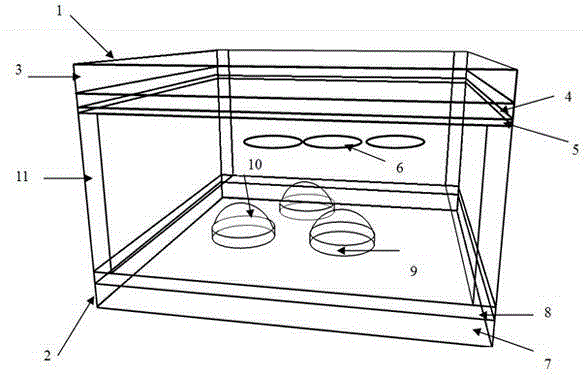

[0023] Embodiment 1, cascade type liquid crystal microlens concave lens array:

[0024] It includes an upper substrate 1, a lower substrate 2, a liquid crystal layer 6, and a gasket 11. The upper substrate 1 includes, from top to bottom, an upper substrate glass 3, an upper substrate ITO film 4, and an upper substrate alignment layer 5; the lower substrate 2 includes a lower substrate glass 7, a lower substrate ITO film 8, a high surface resistance layer 9, a polymer solid lens and a light alignment layer 10, wherein pattern etching is performed on the lower substrate ITO film 8 according to the required pixel size and shape, figure 1 The circle hole pixel pattern etching is shown, the high surface resistance layer 9 is formed by a ZnO layer with a surface resistance value ranging from 0.1-10MΩ / sq or an ITO layer prepared under specific parameters, and the radius of the polymer solid convex lens 10 is etched with the circle hole. The radii are the same, and the positions are i...

Embodiment 2

[0027] Embodiment 2, cascaded liquid crystal microlens convex lens array:

[0028] The implementation structure diagram is still as figure 1 As shown, what is changed is the refractive index of the polymer lens. In the case of embodiment two (n o e 1 -L 2 1 -L 2 2 / 2(n e -n) h~r 2 / 2(n o -n) h, where r is the radius of the polymer lens.

Embodiment 3

[0029] Embodiment 3, a cascaded liquid crystal microlens array for conversion of concave lenses and convex lenses:

[0030] The example case (n o e ), when not powered, L 1 -L 2 >0, it is a concave lens; in the power-on state, L 1 -L 2 2 / 2(n e -n) h~r 2 / 2(n o -n) h, where r is the radius of the polymer lens.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com