Water power balancing debugging method of pipeline system

A technology of pipeline system and debugging method, applied in the field of hydraulic system, can solve problems such as cumbersome adjustment, and achieve the effect of reducing energy consumption, reducing time, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

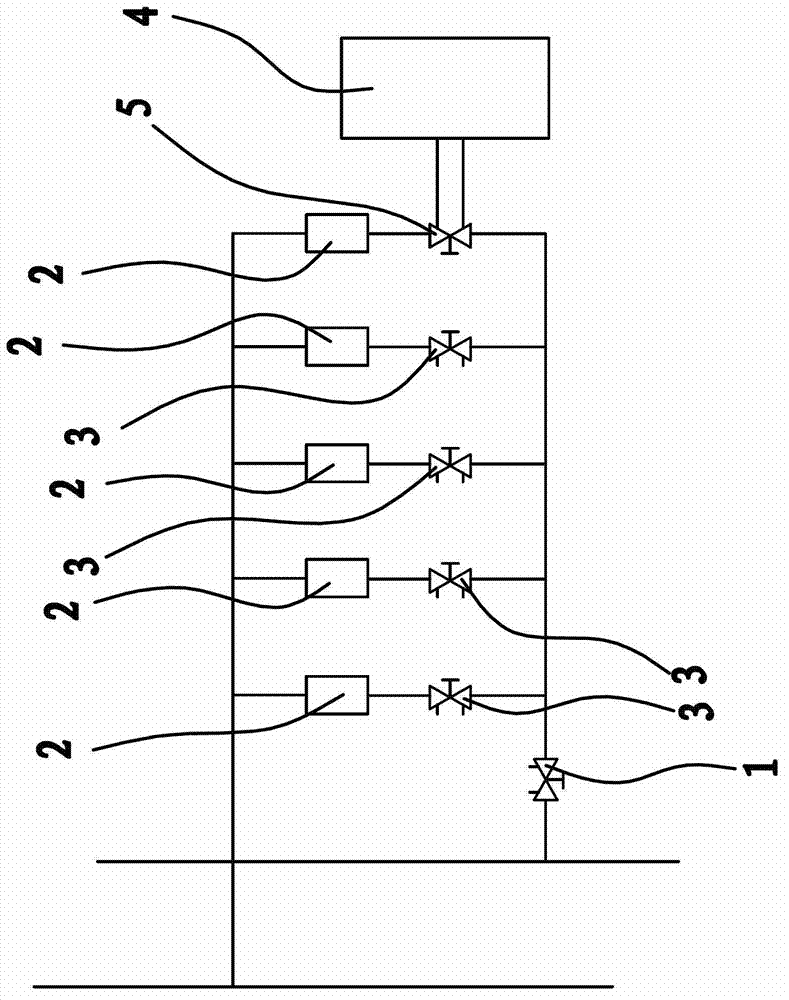

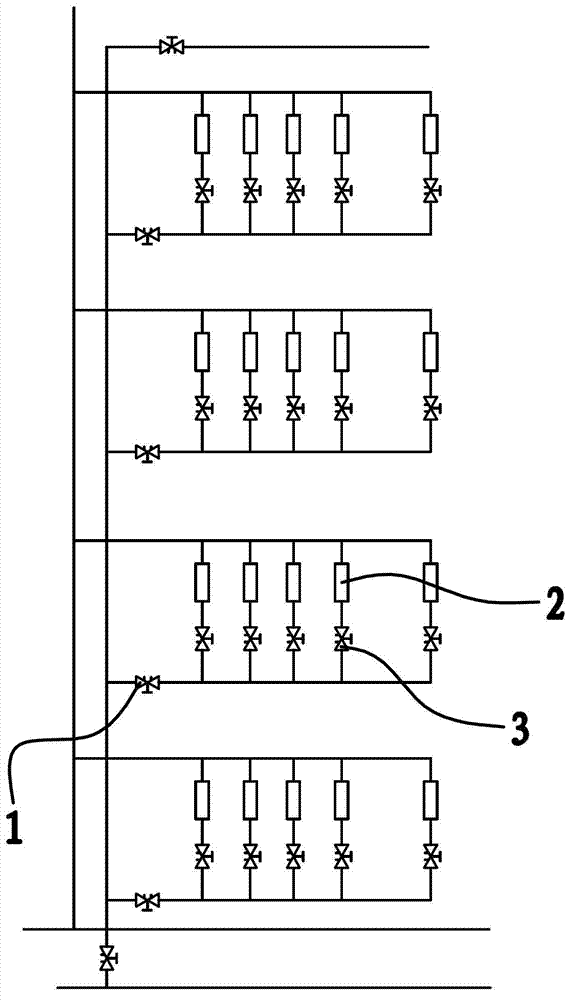

[0025] Such as figure 1 As shown, the pipeline system includes a water inlet pipe and a water return pipe. There are five user terminals 2 connected in parallel between the water inlet pipe and the water return pipe. Each user terminal 2 has a balance valve 3 that can adjust the flow of its branch. It also has a cooperative valve 1 that can regulate the flow of the entire water inlet pipe.

[0026] This debugging method includes the following steps:

[0027] A. Debugging preparation: Select the balance valve at the end user end of the pipeline system as the reference valve, and connect the ordinary differential pressure tester to the reference valve.

[0028] B. Measuring the differential pressure of the reference valve: measure the reference valve 5 with an ordinary tester 4, and obtain the pressure differential △pR continuously measured at the reference valve 5, which is used as a reference value. In this embodiment, the opening of the reference valve 5 is changed to keep ...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, except that there are six user terminals 2 connected in parallel between the water inlet pipe and the water outlet pipe, and at the same time, the pressure difference when the reference valve 5 is fully opened in step B is greater than 3KPA. At this time, the pressure difference when the reference valve 5 is fully opened is used as a reference value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com