Coil component and manufacturing method thereof

A production method and coil component technology, applied in the direction of electrical components, inductors/transformers/magnets, inductors with magnetic cores, etc., can solve problems such as difficult to improve noise, improve noise, avoid mutual contact, and strengthen isolation with the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

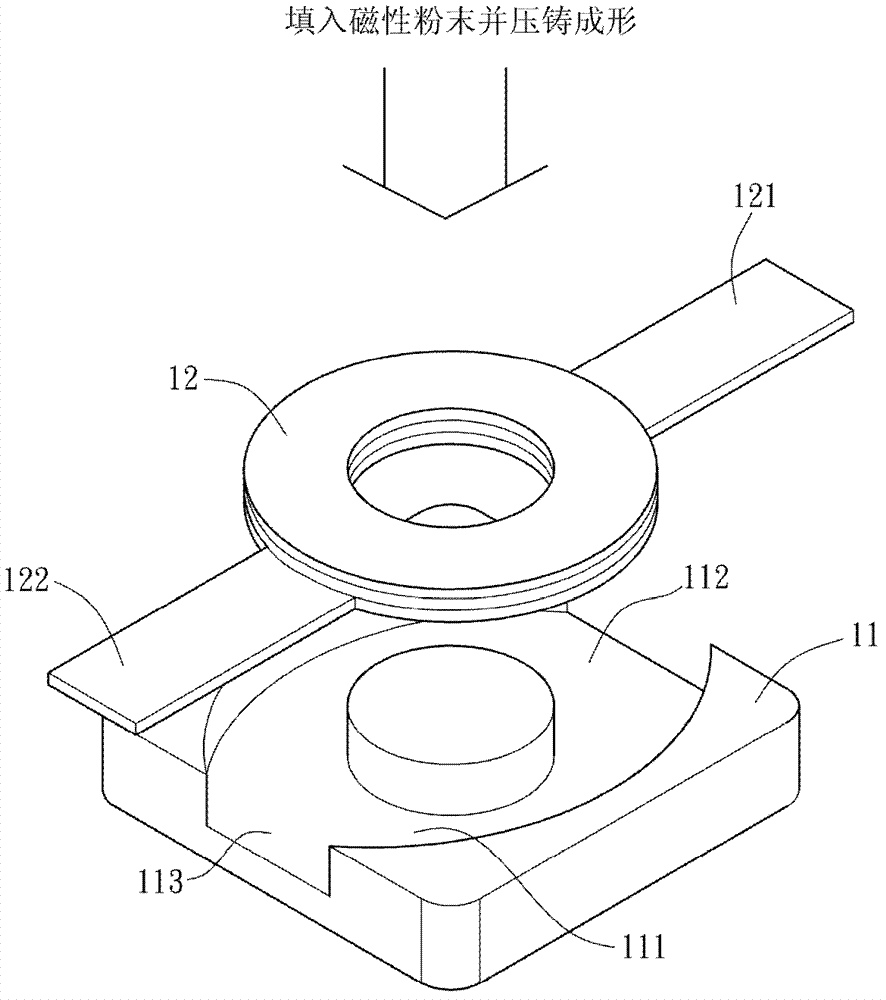

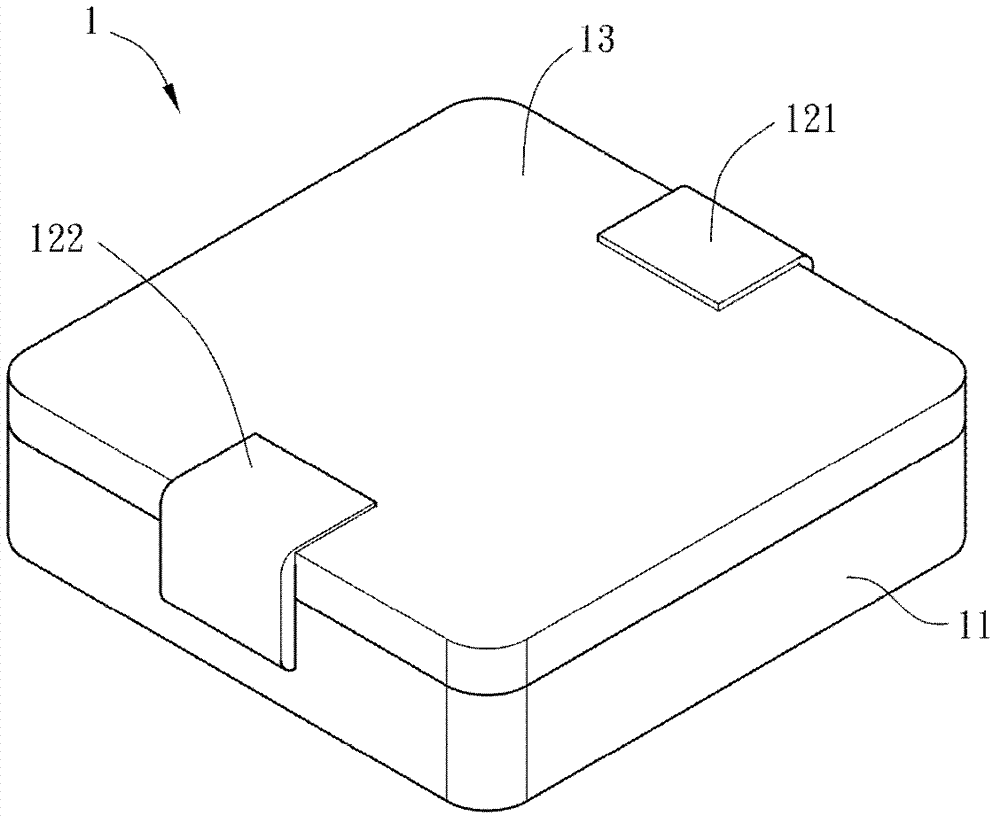

[0057] A coil assembly and a manufacturing method thereof according to preferred embodiments of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference numerals.

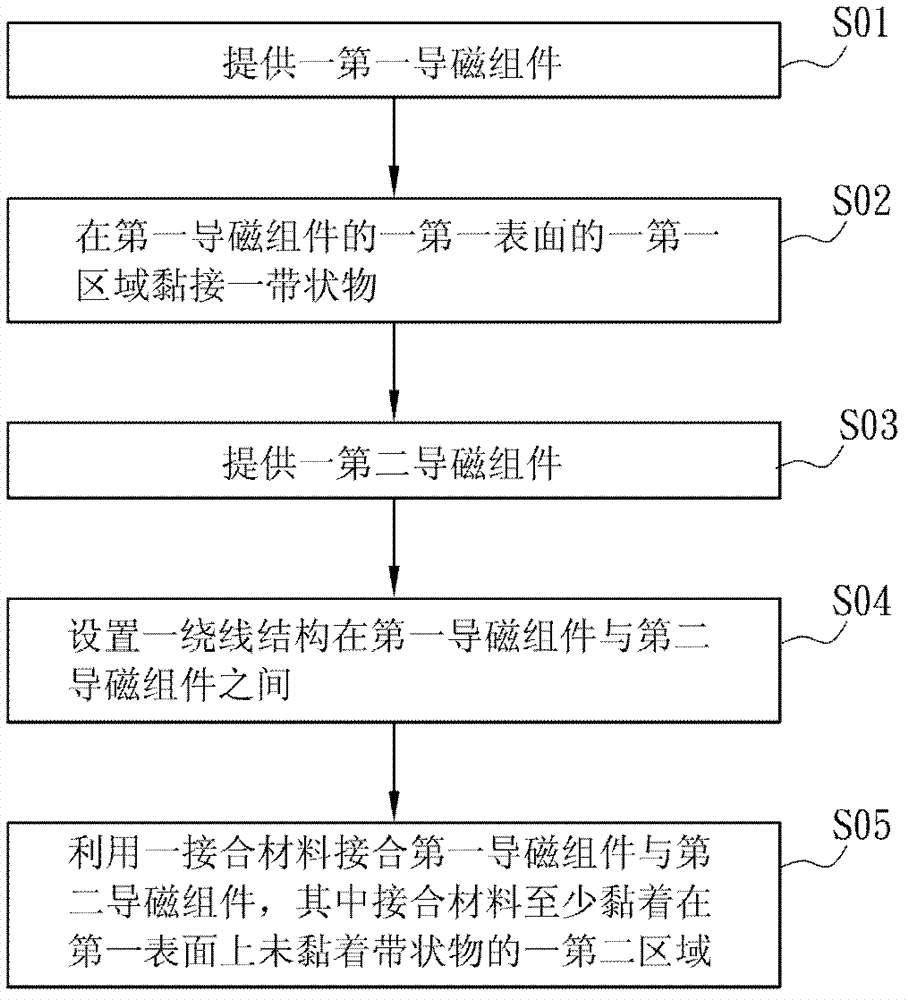

[0058] figure 2 It is a flow chart of a manufacturing method of a coil assembly in a preferred embodiment of the present invention.

[0059] Such as figure 2 As shown, the manufacturing method of the coil assembly includes the following steps:

[0060] Step S01: providing a first magnetically conductive component;

[0061] Step S02: Adhesive a strip on a first area of a first surface of the first magnetically permeable component;

[0062] Step S03: providing a second magnetically conductive component;

[0063] Step S04: setting a winding structure between the first magnetically permeable component and the second magnetically permeable component; and

[0064] Step S05 : Using a bonding material to bond the first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com