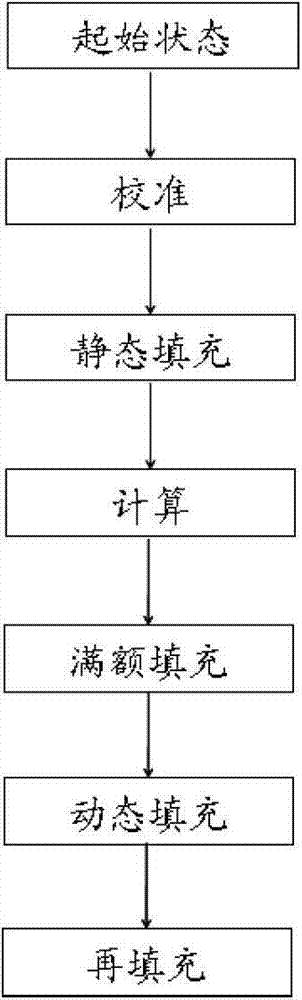

A method for filling a wash tub of a dishwasher with water

A washing basin and dishwasher technology, applied in the washing basin field, can solve the problems of increased tolerance, large space and cost, complicated dishwasher production, etc., and achieves the effect of eliminating drift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

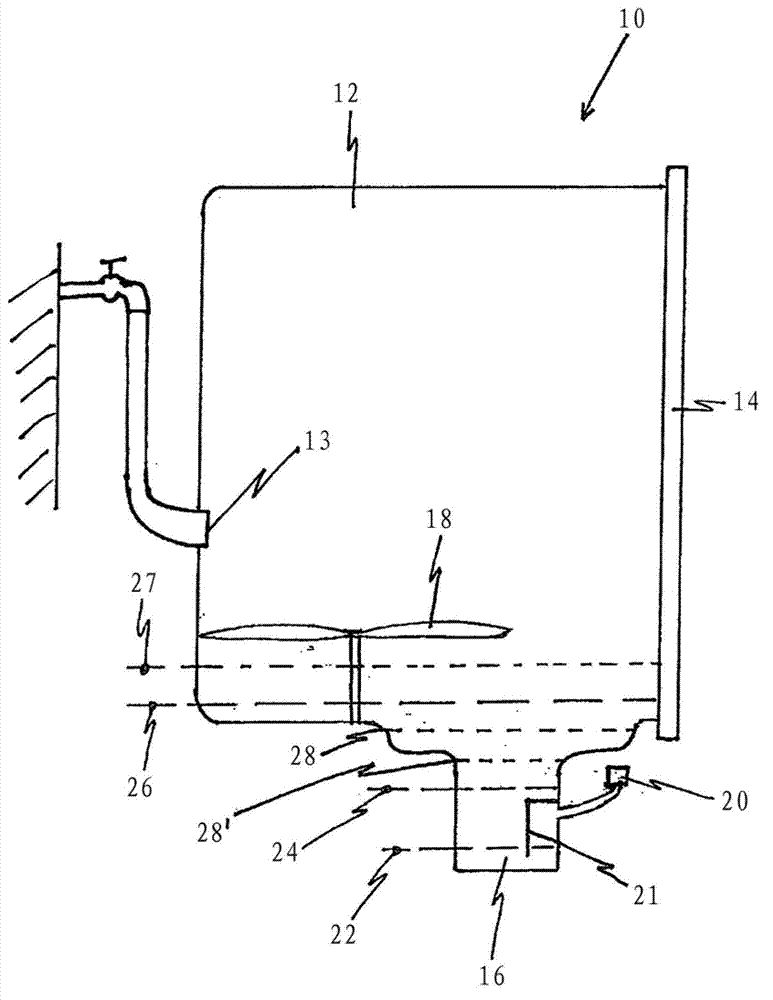

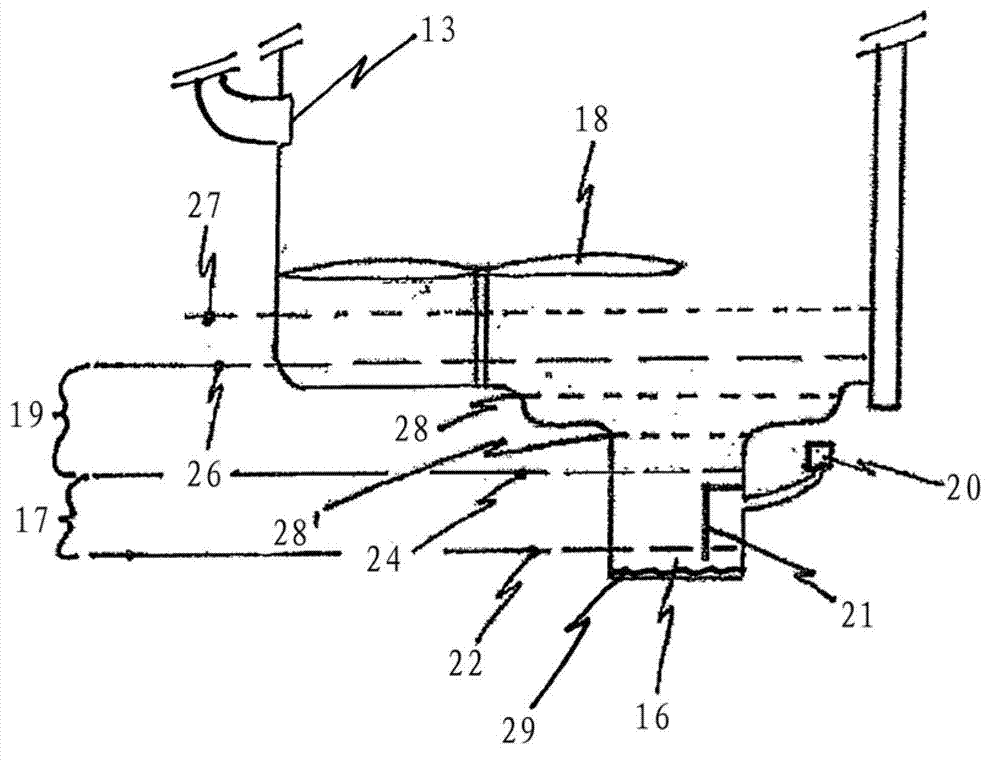

[0081] Such as figure 1 As shown, the dishwasher 10 includes a wash basin 12 for receiving laundry (not shown), the wash basin 12 is composed of a rear wall (on the left side), two opposing side walls (not shown), a top wall (on the top ), the bottom (at the lower end of the wash basin, with an opening fixed to the storage tank 16 for collecting water), the front opening (right side, not indicated), which is defined in figure 1 The center is closed by the loading door 14 at the front. At least one dishwasher sprayer 18 is arranged in the wash tub 12 for spraying pressurized wash water on the laundry. Dishwasher sprinklers receive pressurized wash water from a dishwasher's circulation pump (not shown), which in operation draws water from a corresponding opening (not shown) in the storage tank.

[0082] An analog pressure sensor 20 is arranged next to the storage tank 16 and is hydraulically connected to the storage tank by a connecting pipe. The storage tank includes an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com