Multi-rotor forced mixer

A powerful mixer and multi-rotor technology, applied in mixers, mixers with rotating mixing devices, mixer accessories, etc., can solve the problems of decreased machine running stability, poor mixing uniformity, and increased machine noise, etc. To achieve the effect of improving stability, good vibration resistance, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

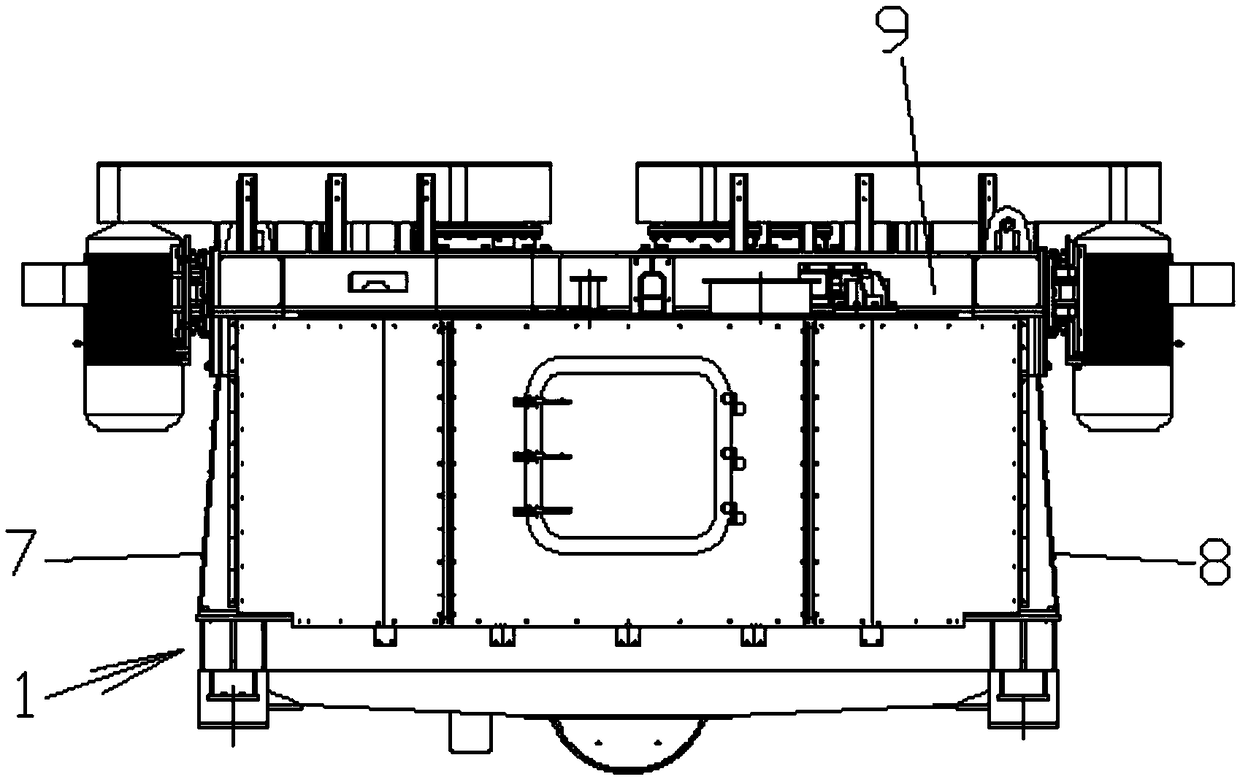

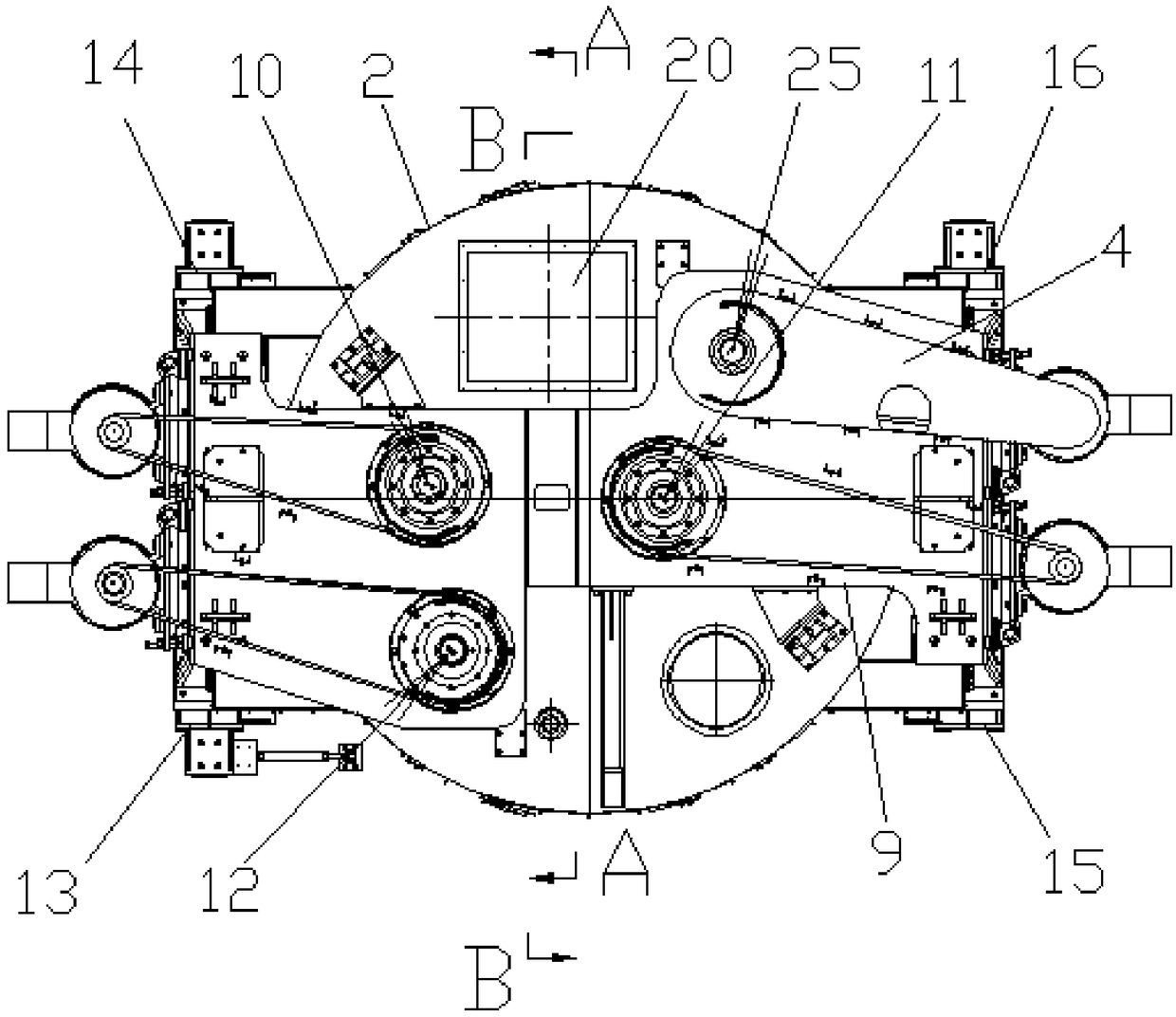

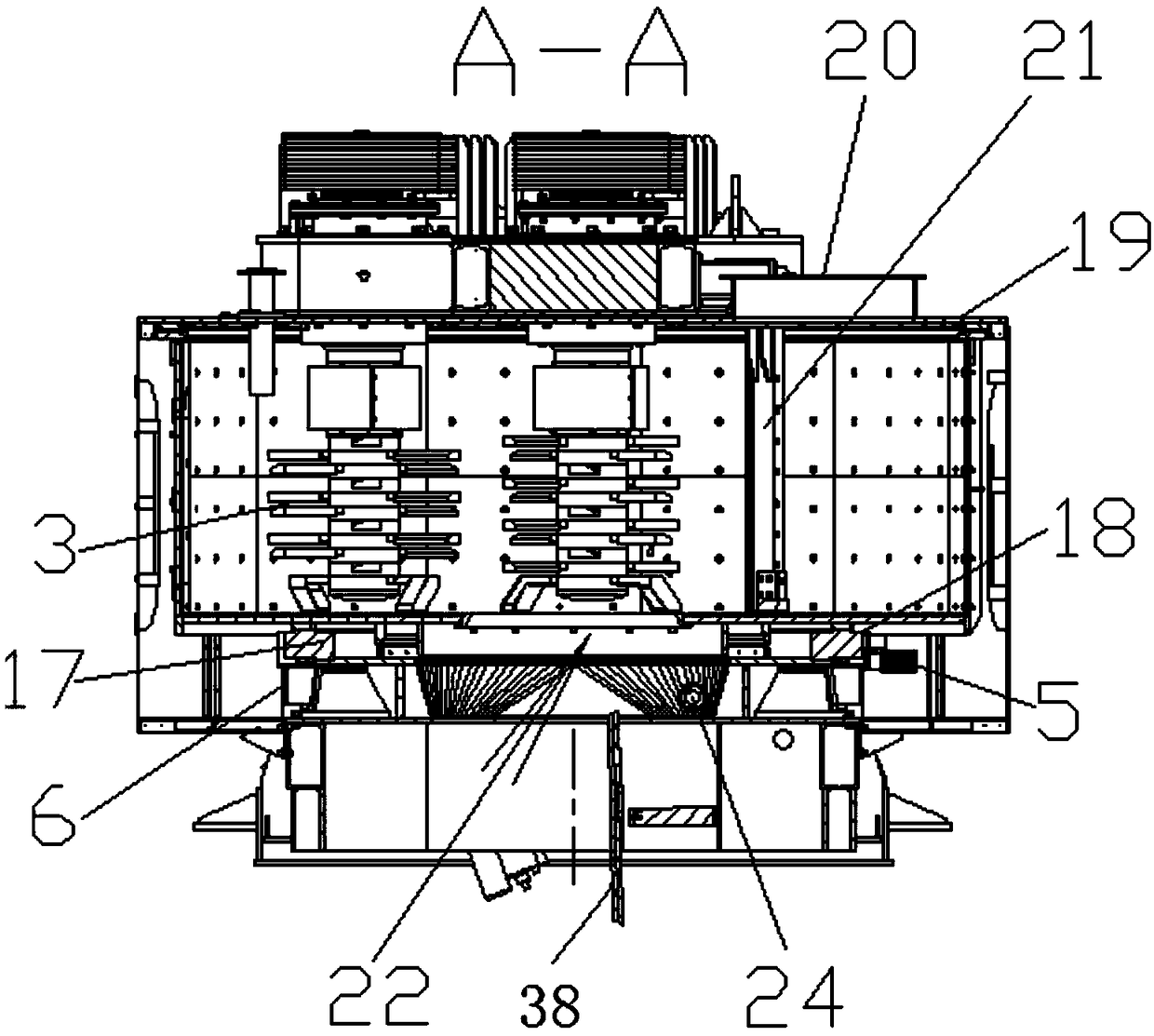

[0070] Such as Figures 1 to 13 Shown is an embodiment of a multi-rotor intensive mixer of the present invention, including a frame 1, a cylinder 2 arranged on the frame 1 for placing mixed materials, and a cylinder 2 arranged on the cylinder 2, the rotor assembly 3 for mixing materials, and the rotor drive mechanism 4 and the cylinder drive mechanism 5 arranged on the frame 1 for respectively connecting and driving the rotor assembly 3 and the cylinder 2 to realize rotation, The frame 1 includes a bottom frame 6, a left column module 7 and a right column module 8 that are respectively arranged on both sides of the bottom frame 6 and extend upward, and are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com