High-efficiency vehicular hedge clipper with two clipping faces

A hedge trimmer, vehicle-mounted technology, applied to hedge trimming equipment, etc., can solve problems such as large manpower and financial resources, no efficient hedge trimming methods, and affect the normal traffic of expressways, etc., to achieve high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

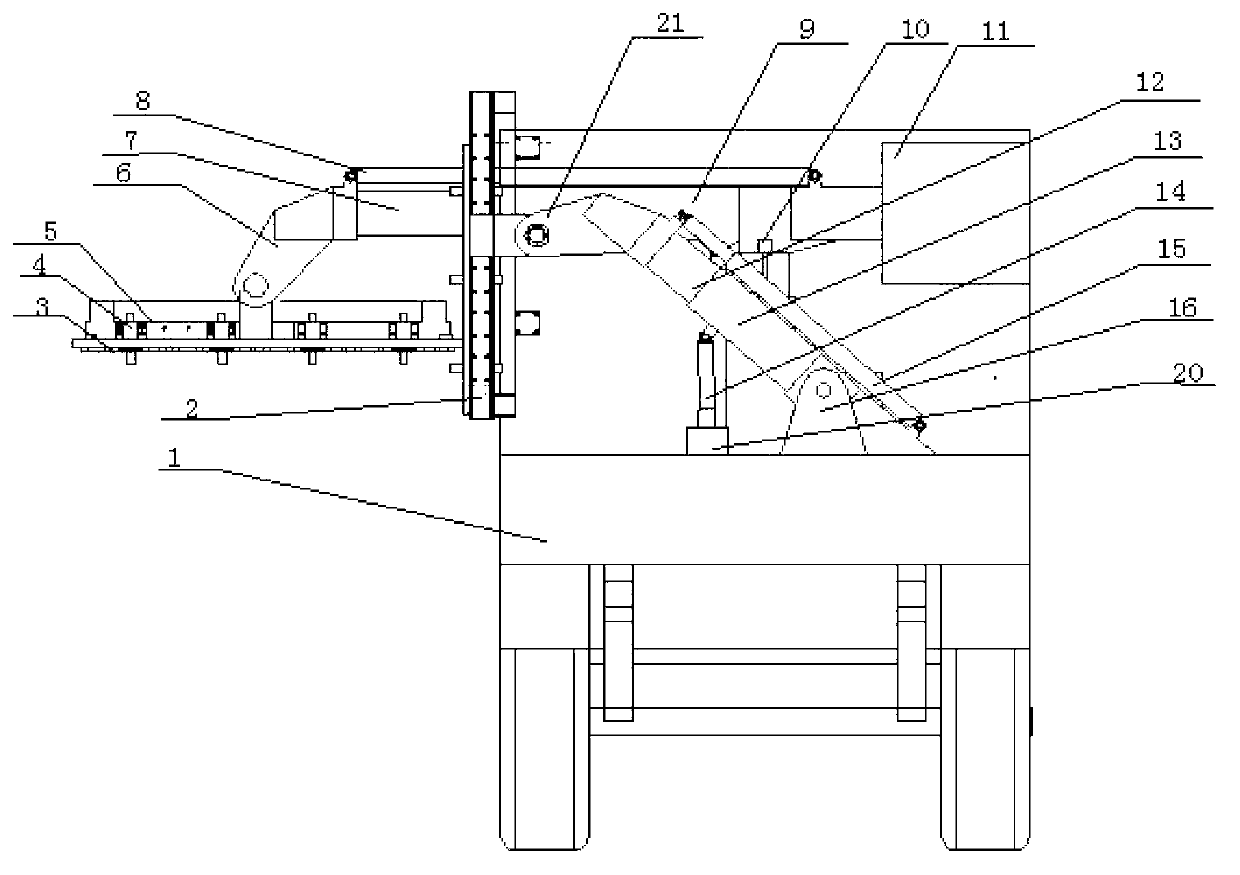

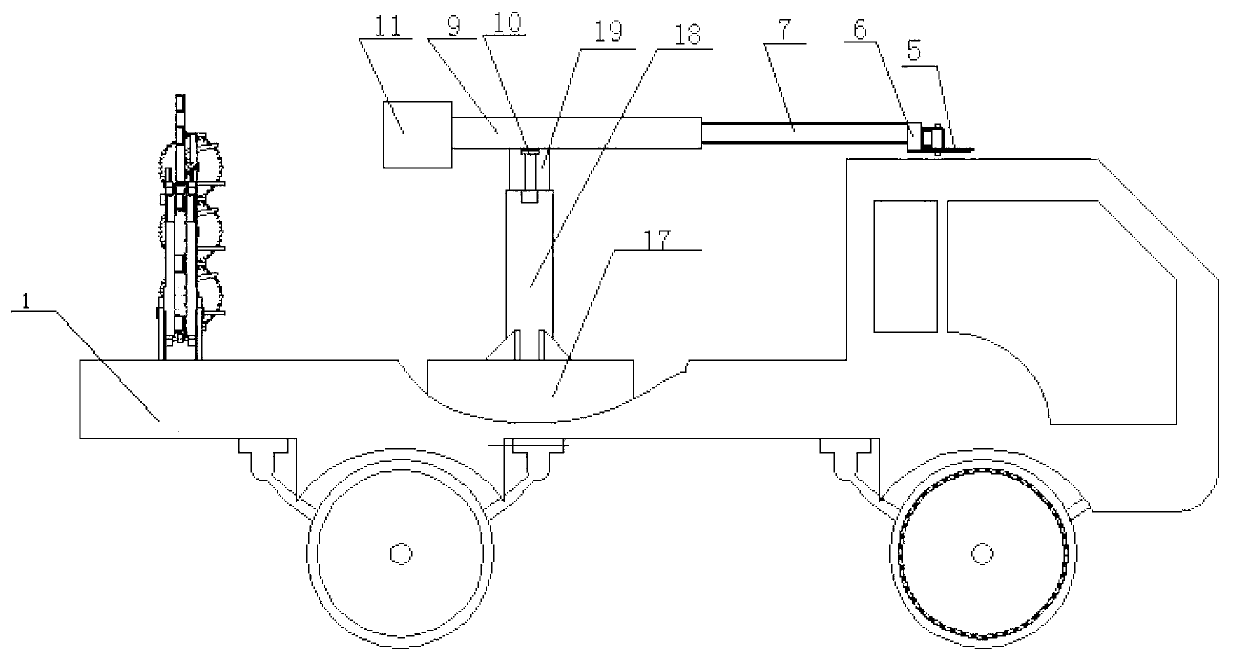

[0010] like figure 1 - As shown in 2, the present invention has the high-efficiency vehicle-mounted hedge trimmer with two trimming surfaces, and the vertical plane knife rest 2 and the horizontal plane knife rest 5 are independently installed respectively on the carrying vehicle 1.

[0011] The installation method of the vertical surface tool holder 2 is: the bearing car 1 is fixed with a support Ⅱ16 by means of bolt connection, the support Ⅱ16 is connected with one end of the static arm Ⅱ13 through a pin shaft, and the other end of the static arm Ⅱ13 is sleeved with a moving arm Ⅱ12, the other end of the movable arm Ⅱ12 is fixedly connected with the connection block Ⅱ21, and the connection block Ⅱ21 is connected with the vertical surface tool rest 2 by bolts, so that when the operation starts, the angle required for trimming the vertical surface knife rest 2 can be manually adjusted; The base II20 of the lifting cylinder II14 is fixed on the carrier vehicle 1, the telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com