Tobacco dust flat bag horizontal insertion, off-line deashing and dedusting unit modular combined deduster unit

A unit module and dust technology, which is applied in the field of tobacco machinery, can solve the problems that the dust collector cannot work continuously for a long time, the dust treatment system and the dust conveying system are blocked, and the compressed air pressure is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

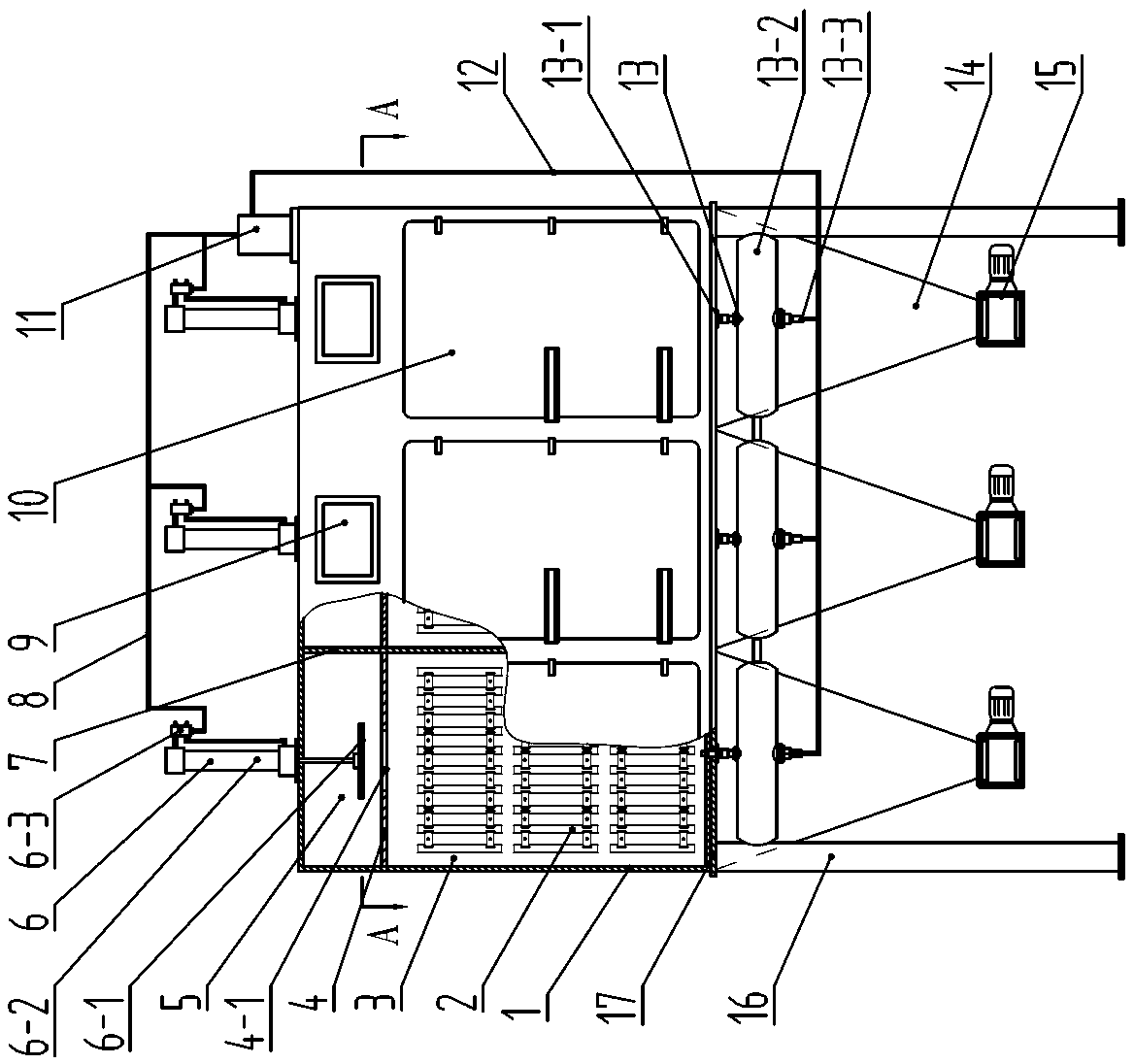

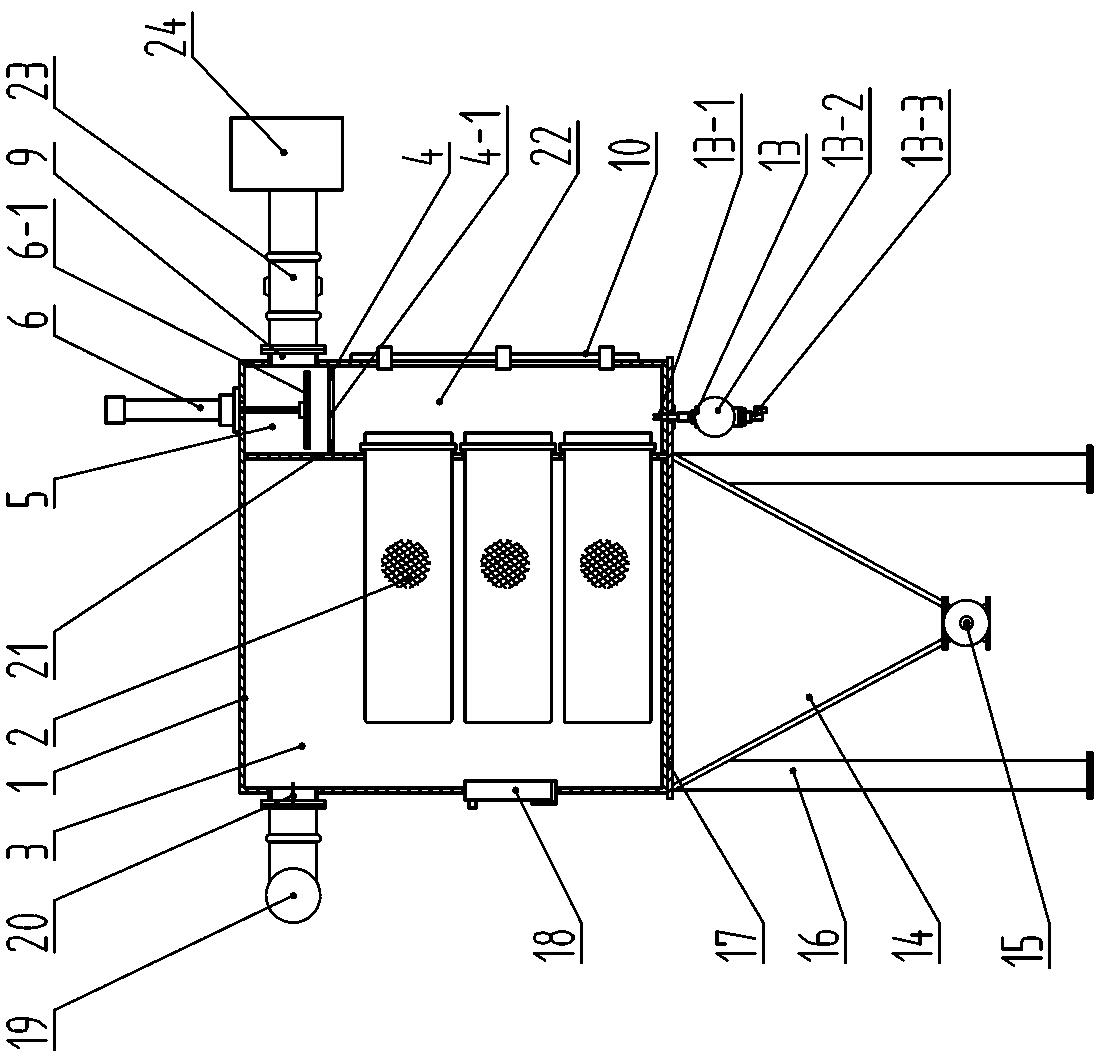

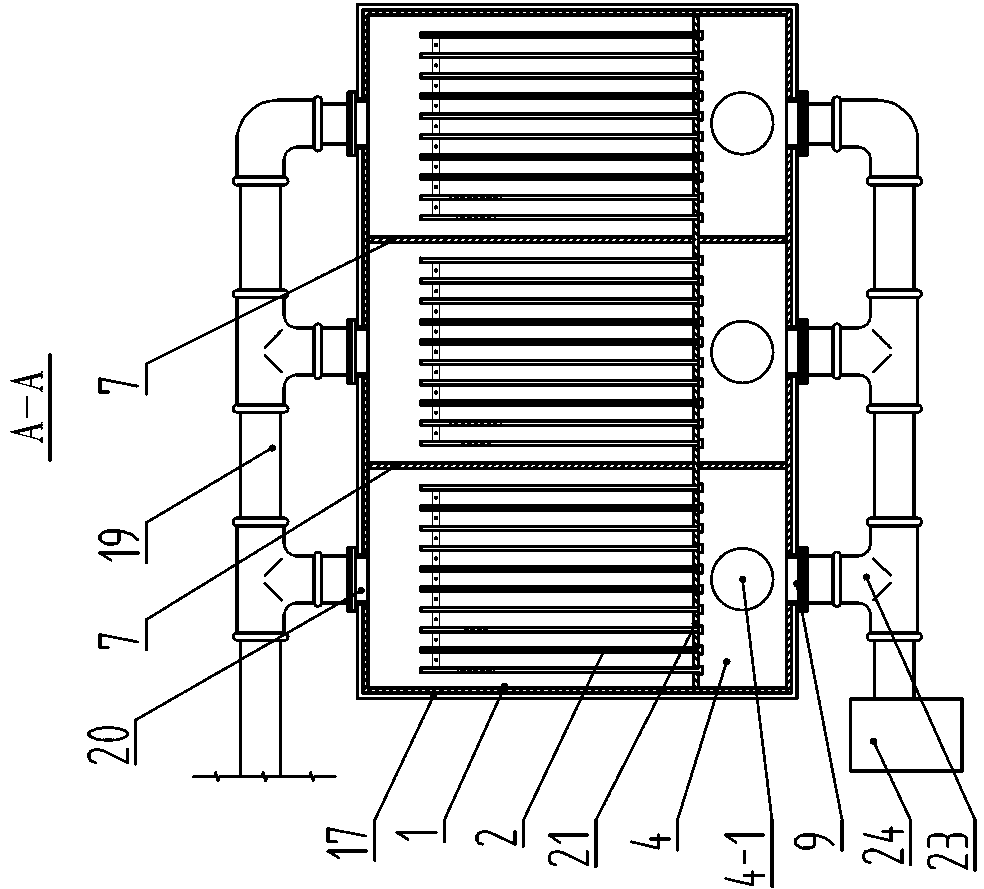

[0021] Such as figure 1 , 2 , 3. As shown: a flat bag of tobacco dust horizontally inserted into the offline dust removal unit modular combination dust removal unit, the dust removal unit module includes: box body, flat filter 2, gas circuit switch valve group 6, pulse injection System 13, ash hopper 14 and ash discharge valve 15. The box is a fully enclosed rectangular box with a steel structure, the upper part of the rear side plate of the box body has an air inlet 20 to be purified, and the middle part of the rear side plate of the box body has an observation window 18 . The top of the casing front side panel has a clean air outlet 9, and the middle part of the casing front side panel has maintenance personnel 10. A filter mounting plate 21 parallel to the front and rear side plates is fixed on the end of the box cavity close to the front side plate, and the filter mounting plate 21 divides the box cavity into a dust gas chamber 3 and a clean air chamber 22 . A plurality...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap