Non-aqua-system pigment ink for ink jet

A non-aqueous, non-aqueous solvent technology, applied in the direction of ink, applications, household appliances, etc., can solve the problems of roller transfer pollution, ink viscosity increase, and performance difficulties, etc., to achieve high printing density, reduce cross-printing, prevent The effect of transfer contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these.

[0060]

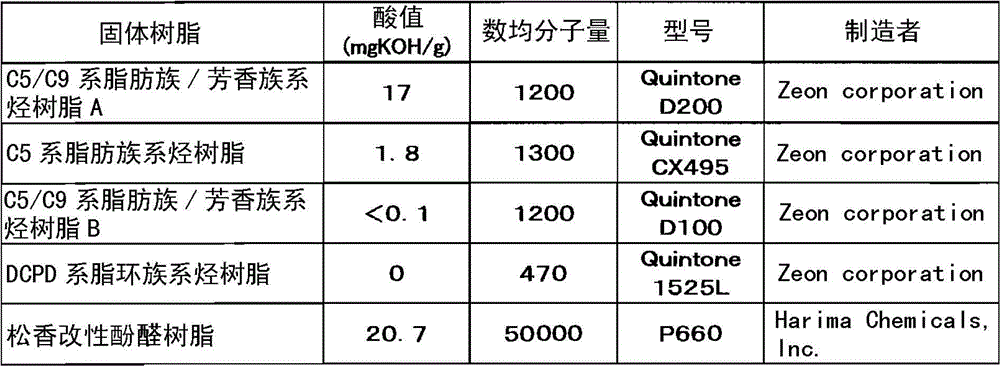

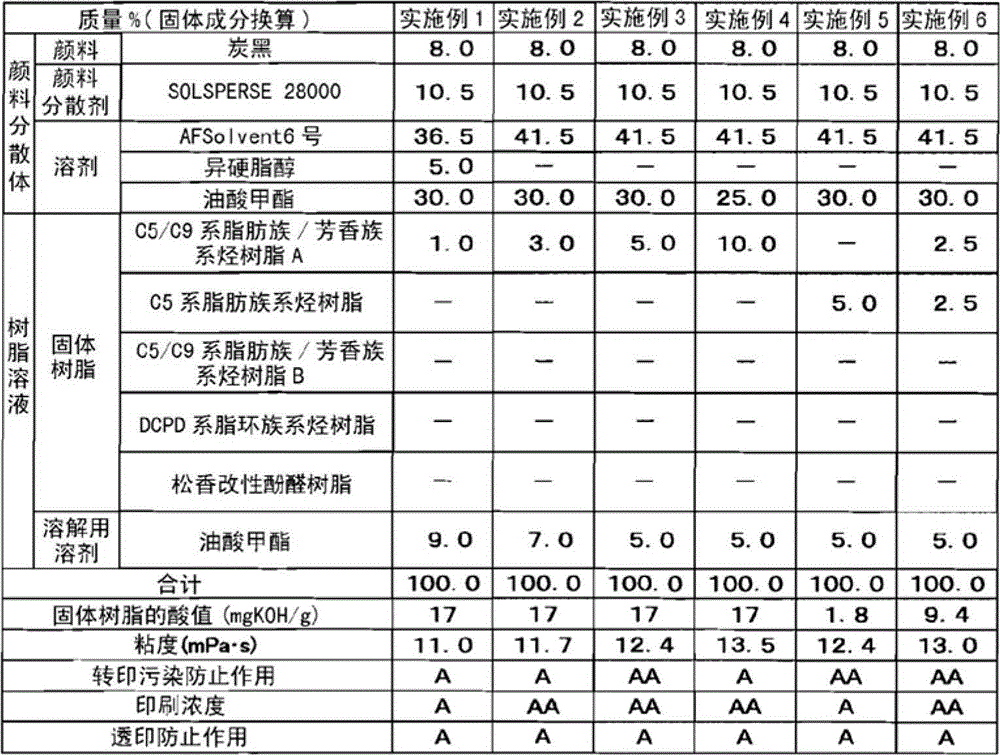

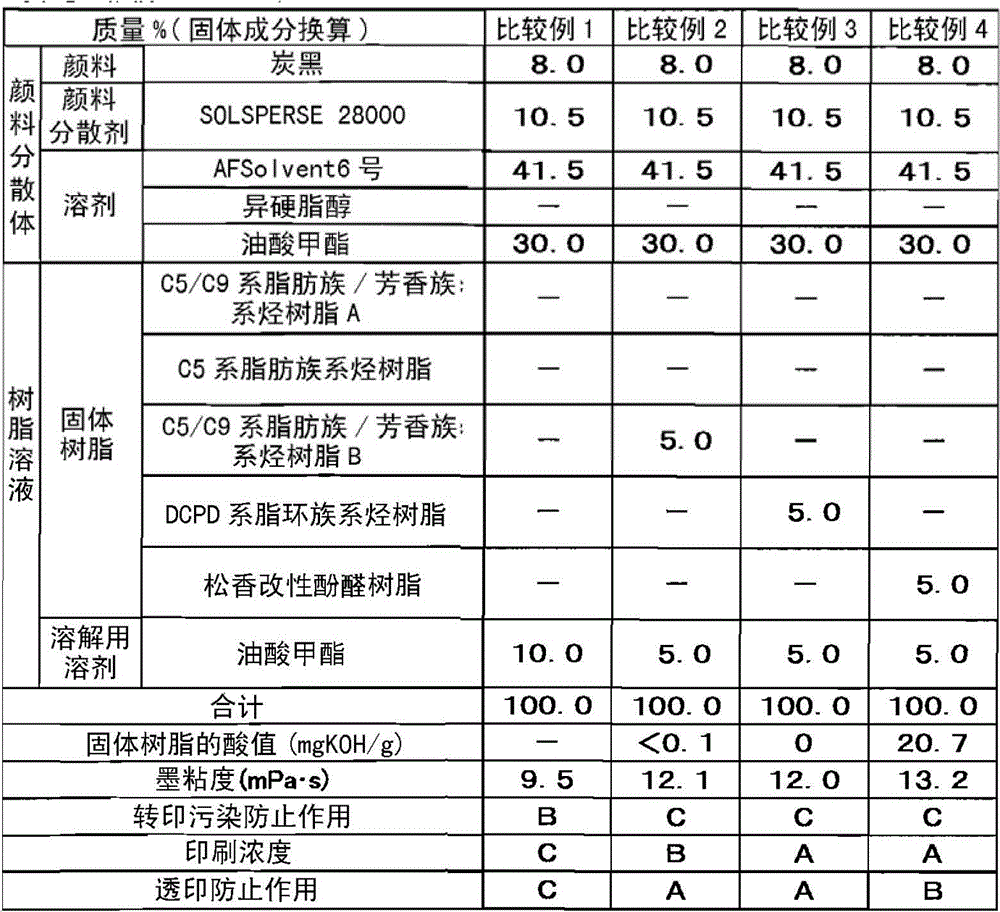

[0061]Mix 50% by mass of each solid resin shown in Table 1 with 50% by mass of methyl oleate (EXCEPARL "M-OL" produced by Kao Corporation), heat to 120°C, and dissolve it while stirring to obtain a composition as follows: Resin solutions shown in Table 2 and Table 3. In addition, the resin solution of Example 6 is a mixture of C5 / C9 aliphatic / aromatic hydrocarbon resin A and C5 aliphatic hydrocarbon resin in a mass ratio of 1:1, 50% by mass and methyl oleate 50% by mass mixed.

[0062] Table 1

[0063] [Table 1] Details of solid resin

[0064]

[0065]

[0066] The pigments, pigment dispersants, and non-aqueous solvents were premixed in the formulations shown in Table 2 and Table 3, and then dispersed for 4 hours using a swing mill (manufactured by SEIWA GIKEN Co., Ltd.) to obtain pigment dispersions. After mixing the obtained pigment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap