Thermal printing head capable of not only improving lettering quality but also prolonging service life

A thermal print head, quality technology, applied in the direction of printing device, printing, etc., to achieve the effect of improving service life, increasing printing density, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

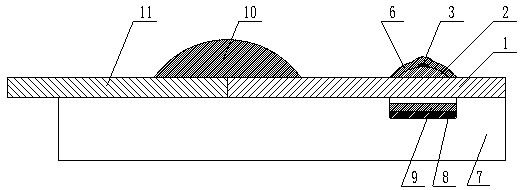

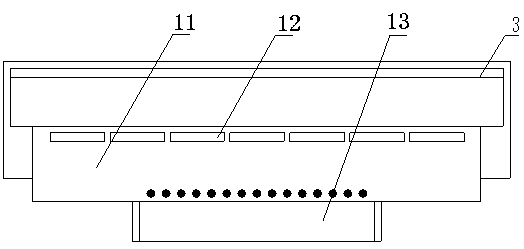

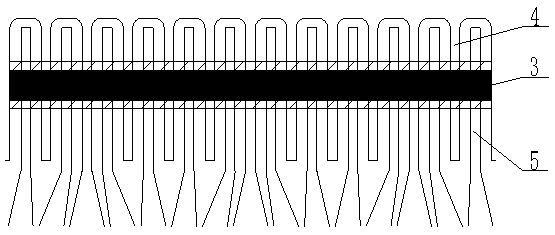

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as Figure 1-3 As shown, the thermal printhead that can improve the printing quality and service life involved in the present invention includes a ceramic substrate 1, on which a lead-free amorphous glass underglaze layer 2 is fully or partially printed, Sinter the ceramic substrate 1 with the underglaze layer 2 at a temperature of 1200°C-1300°C; then print and sinter the conductive paste on the surface of the ceramic substrate 1 and the underglaze layer 2 at a sintering temperature of 800°C-920°C, and then use it up Common electrodes 4 and individual electrodes 5 are formed by engraving technology, and then strip-shaped coating is carried out along the main printing direction of the thermal print head, and sintered at a temperature of 780°C-850°C to form a heating resistor 3 with a thickness of 4 μm to 8 μm; image 3 As shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap