Gravure printing method

一种凹版印刷、凹版的技术,应用在水性油墨的凹版印刷领域,能够解决减少油墨转印量、干燥性差等问题,达到优异亮度适性、高印刷浓度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

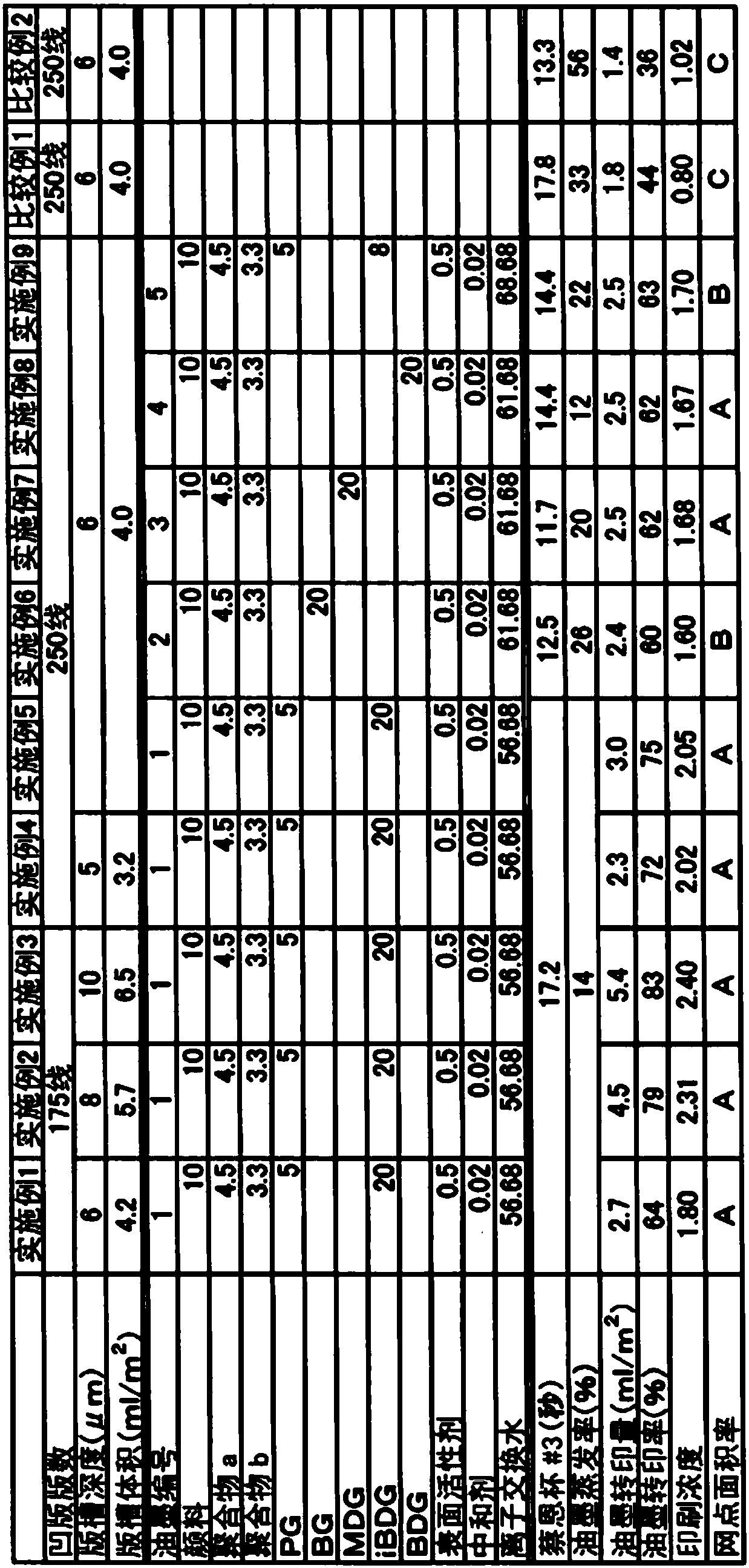

[0204] Hereinafter, the present invention will be further specifically described by way of examples and the like. In the following examples and the like, various physical properties were measured by the following methods. In addition, "parts" and symbols "%" mean "parts by mass" and "% by mass" unless otherwise noted.

[0205] (1) Determination of the weight average molecular weight of the polymer

[0206] Phosphoric acid and lithium bromide were dissolved in N,N-dimethylformamide at concentrations of 60mmol / L and 50mmol / L, respectively, as eluents, and gel permeation chromatography [GPA apparatus manufactured by Tosoh Co., Ltd. (HLA-8120GPA), Tosoh Co., Ltd. column (TSK-GEL, α-M×2 pieces), flow rate: 1 mL / min] to measure the molecular weight of the water-insoluble polymer. In addition, monodisperse polystyrene with a known molecular weight was used as a standard substance.

[0207] (2) Determination of average particle size of particles

[0208] Measurement was performed us...

manufacture example I

[0211] ・Manufacture example 1 (manufacture of water-insoluble polymer a solution)

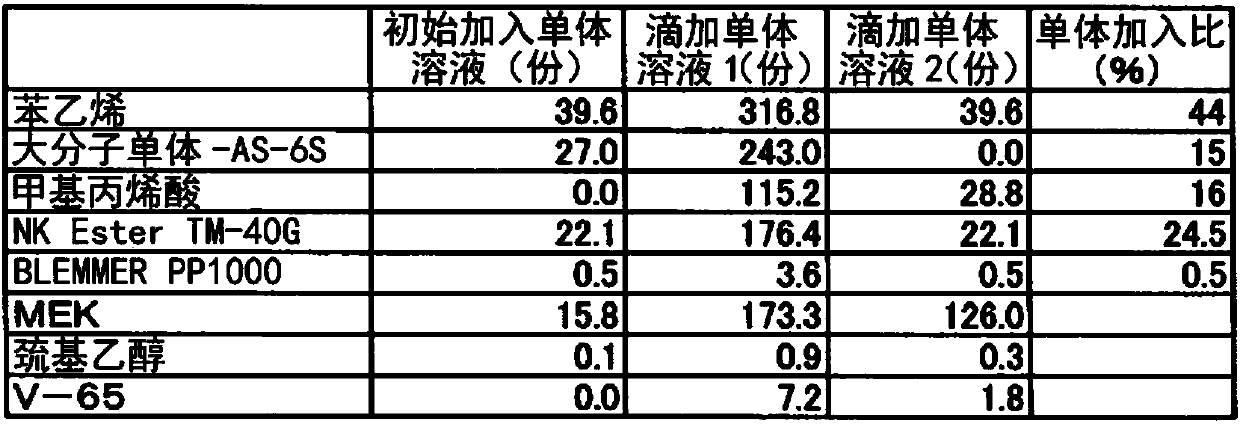

[0212] In the reaction vessel equipped with two dropping funnels 1 and 2, put the monomer, solvent and polymerization initiator (2,2'-azobis(2, 4-Dimethylvaleronitrile) (manufactured by Wako Pure Chemical Industries, Ltd., trade name: V-65), polymer chain transfer agent (2-mercaptoethanol) (manufactured by KISHIDA Chemical Co., Ltd.) were mixed and replaced with nitrogen while obtaining the initially charged monomer solution.

[0213] Next, mix the monomers, solvents, polymerization initiators, and chain transfer agents shown in the "dropping monomer solution 1" in Table 1 to obtain the dropping monomer solution 1, and then put it into the dropping funnel 1 for nitrogen replacement . In addition, the monomer, solvent, polymerization initiator, and polymerization chain transfer agent shown in the "dropping monomer solution 2" in Table 1 were mixed to obtain the dropping monomer solution 2, and...

manufacture example II

[0220] ・Manufacture Example II (Manufacture of a dispersion of water-insoluble polymer b particles)

[0221] 0.5 g of methacrylic acid, 14.5 g of methyl methacrylate (manufactured by Wako Pure Chemical Industries, Ltd.), 2-ethylhexyl acrylate (manufactured by Wako Pure Chemical Industries, Ltd.) were placed in a reaction vessel equipped with a dropping funnel. manufactured) 5.0 g, LATEMUL E-118B (sodium polyoxyethylene alkyl ether sulfate 11.1 g, manufactured by Kao Co., Ltd., surfactant), potassium persulfate (manufactured by Wako Pure Chemical Industries, Ltd.) as a polymerization initiator 0.2 g and 282.8 g of ion-exchanged water were mixed at 150 rpm and replaced with nitrogen to obtain an initial monomer solution.

[0222] 9.5 g of methacrylic acid, 275.5 g of methyl methacrylate, 95.0 g of 2-ethylhexyl acrylate, 35.1 g of LATEMULE-118B, 0.6 g of potassium persulfate, and 183.0 ion-exchanged water are mixed at 150 rpm to drop monomer The solution was put into the droppin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com